Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Children's Safe Flavoring Dental Floss Pick

| Brand: | OEM/Ok Floss |

| Floss material: | UHMWPE,Charcal as customized |

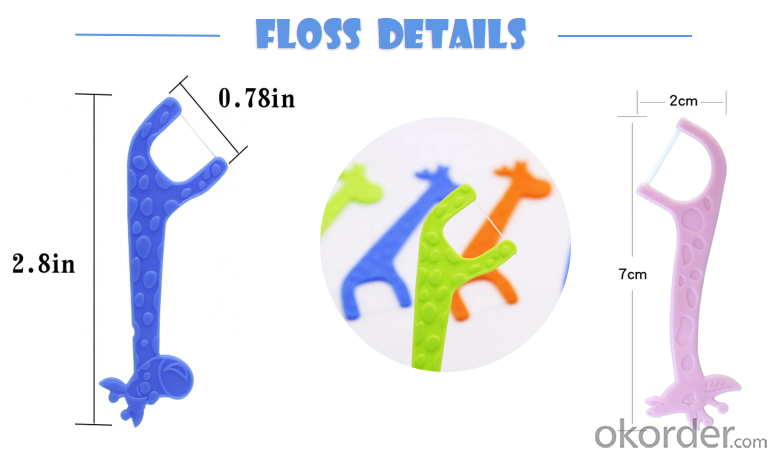

| Size: | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax: | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor: | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color: | Floss original color |

| Floss original color: | Individual bulk PP bag/individual paper box/as customized |

| Applications: | Family,Hotel,Travel,Supermarket |

| Shape: | Bear,Giraffe,Cola |

| Lead time: | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

OEM SERVICE SMALL MOQ FACTORY PRICE HIGH QUALITY INTERNATIONAL CERTIFICATE

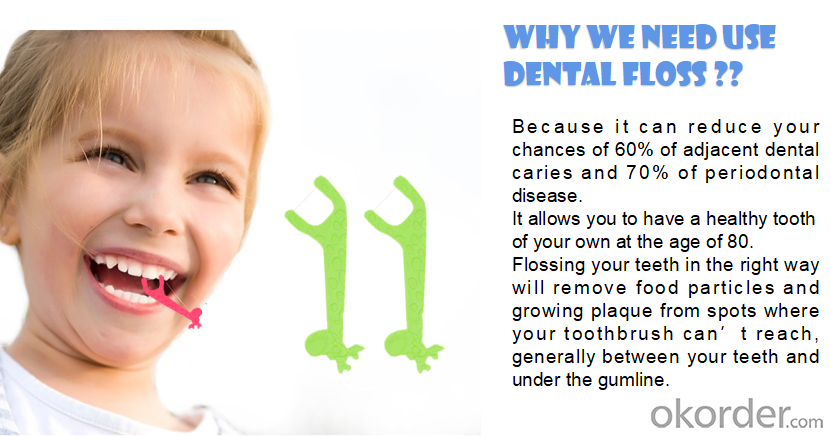

REDUCE ADJACENT DENTAL CARIES

DENTAL FLOSS FOR KIDS

FOOD-GRAD MATERIAL; FIBER FLOSS;MULBERRY SILK POLYACTIC ACID BAMBOO CHARCOAL

DENTAL FLOSS DETAILS & SIZE

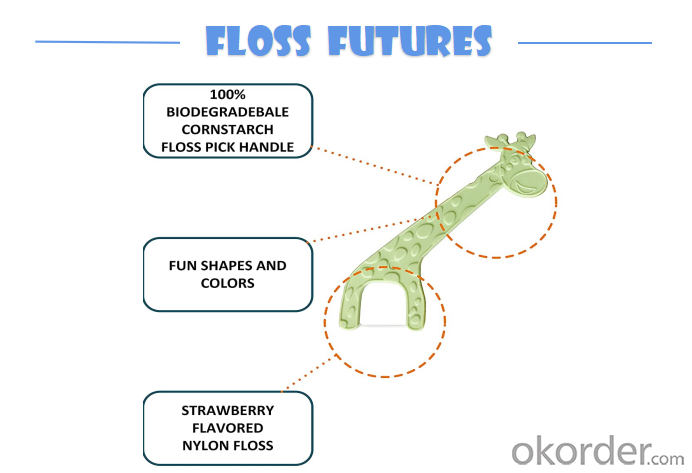

100% BIODEGRADEBALE CORNSTRACH FLOSS PICK HANDLE;FUN SHAPES AND COLORS

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:Are there any risks or side effects associated with medical plastic?

- Yes, there are potential risks and side effects associated with medical plastic. Some plastics may release harmful chemicals, such as phthalates or bisphenol A, which could have adverse effects on human health. Additionally, certain individuals may have allergic reactions to specific types of medical plastic. It is important for healthcare professionals to carefully assess the safety and compatibility of medical plastics before using them in clinical settings.

- Q:How are medical plastics used in imaging equipment?

- Medical plastics are used in imaging equipment primarily for their ability to provide excellent clarity and transparency. They are used in the construction of X-ray machines, CT scanners, and MRI machines, where they are utilized as protective shields, housings, and components. These plastics are chosen for their radiolucency, durability, and resistance to chemicals, making them essential in ensuring accurate and safe medical imaging procedures.

- Q:How is medical plastic used in IV tubing and bags?

- Medical plastic is used in IV tubing and bags to provide a safe and sterile environment for the administration of fluids and medications. The plastic used is specifically designed to be biocompatible, non-reactive, and resistant to contamination. It ensures the integrity of the IV system, preventing leakage and maintaining the fluid's purity, while also allowing for easy monitoring and control of flow rates.

- Q:What are the considerations for preventing the release of toxic fumes from medical plastic during manufacturing?

- There are several considerations for preventing the release of toxic fumes from medical plastic during manufacturing: 1. Material Selection: Choosing the right type of plastic with low toxicity is crucial. Medical-grade plastics that meet regulatory standards and have low levels of volatile organic compounds (VOCs) are preferred. 2. Ventilation Systems: Implementing proper ventilation systems in the manufacturing facility helps to remove any fumes or gases that may be released during the manufacturing process. This ensures a safe working environment and prevents the accumulation of toxic fumes. 3. Manufacturing Processes: Employing efficient and controlled manufacturing processes reduces the likelihood of toxic fume release. Implementing closed systems or using automated machinery can minimize exposure to harmful fumes. 4. Monitoring and Testing: Regular monitoring and testing of the manufacturing process and finished products are essential to ensure compliance with safety standards. This helps to identify any potential issues or risks related to toxic fume release. 5. Regulatory Compliance: Adhering to relevant regulations and standards, such as those set by the Food and Drug Administration (FDA) and other regulatory bodies, is critical. Compliance ensures that the manufacturing process follows specific guidelines for the prevention of toxic fume release. By considering these factors, manufacturers can minimize the risk of toxic fume release during the production of medical plastic, ensuring the safety of both the workers and the end-users of the products.

- Q:Can medical plastics be used in wound closure devices?

- Yes, medical plastics can be used in wound closure devices. They are commonly used in various types of wound closure products such as sutures, staples, and adhesive strips. Medical plastics offer properties like biocompatibility, flexibility, and strength, making them well-suited for wound closure applications.

- Q:Can medical plastic be used in respiratory devices?

- Yes, medical plastic can be used in respiratory devices. It is commonly used in the manufacturing of components such as tubing, connectors, and masks due to its durability, flexibility, and biocompatibility.

- Q:How is medical plastic used in neonatal incubators?

- Medical plastic is used in neonatal incubators to provide a safe and sterile environment for premature babies. It is used to construct the walls, windows, and doors of the incubator, ensuring a controlled temperature, humidity, and oxygen level. The plastic also allows healthcare professionals to easily monitor and access the baby while protecting them from external contaminants and maintaining a sterile environment.

- Q:Are medical plastics resistant to chemicals?

- Yes, medical plastics are generally resistant to chemicals. They are specifically designed and manufactured to withstand various chemical substances commonly used in medical settings, ensuring their durability and preventing any negative reactions or degradation.

- Q:Are there any limitations to the use of medical plastics?

- Yes, there are limitations to the use of medical plastics. Some limitations include the potential for leaching of chemicals into the body, the risk of allergic reactions or sensitivities, and the inability to withstand extreme temperatures or certain sterilization methods. Additionally, the disposal and environmental impact of medical plastics is a concern.

- Q:Can medical plastics be used for bone replacement or regeneration?

- Yes, medical plastics can be used for bone replacement or regeneration. Medical grade plastics, such as biocompatible polymers, have been developed specifically for use in medical applications. These plastics have properties that make them suitable for bone replacement, including biocompatibility, durability, and the ability to support bone growth. They can be used in various forms, such as implants or scaffolds, to aid in bone regeneration and repair.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Children's Safe Flavoring Dental Floss Pick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 box

- Supply Capability:

- 100000 box/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords