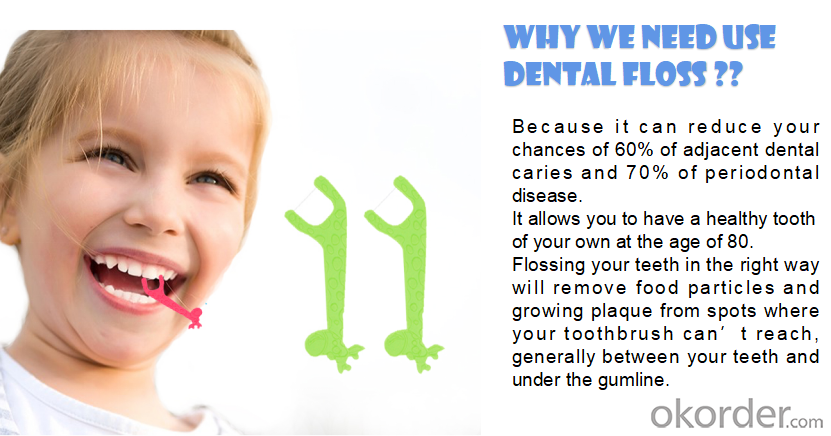

Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Correcting smell dental floss suitable for children

| Brand | Ok Floss |

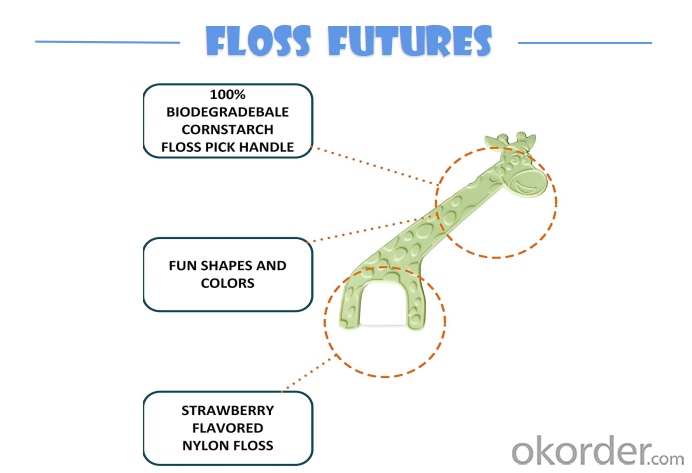

| Floss material | UHMWPE |

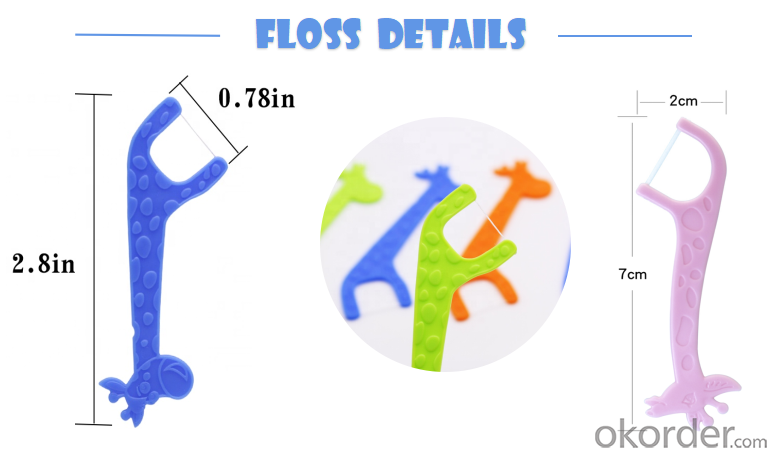

| Size | Length: 7.5cm Width:2.0cm Thickness: 0.2cm U-Slot: 2.0cm Floss: 1.2cm |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

| Flavor | Mint / green tea /fruit |

| Color | white,yellow,orange |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Restaurant |

| Shape | Bear,Giraffe |

| Lead time | 20-30days |

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEM make?

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:How do medical plastics contribute to the portability of medical devices?

- Medical plastics contribute to the portability of medical devices through their lightweight and durable properties. By using plastics in the manufacturing of medical devices, they become more compact, easier to handle, and can be transported more conveniently. Additionally, medical plastics offer resistance to various chemicals, moisture, and temperature changes, ensuring that the devices remain functional and reliable during transportation.

- Q:What are the considerations when selecting medical plastics for specific applications?

- When selecting medical plastics for specific applications, there are several important considerations to keep in mind. First and foremost, the material must be biocompatible, meaning it does not elicit any harmful reactions or toxic effects when in contact with the human body. Additionally, the plastic should possess the necessary mechanical properties to withstand the intended use, such as strength, flexibility, and durability. Other factors to consider include chemical resistance, sterilizability, and cost-effectiveness. It is crucial to consult with experts and comply with regulatory standards to ensure the chosen medical plastic is suitable and safe for the intended application.

- Q:How does medical plastic contribute to the development of tele-audiology technologies?

- Medical plastic plays a crucial role in the development of tele-audiology technologies by providing the necessary materials for the production of various components. It allows for the creation of lightweight, durable, and biocompatible devices such as ear molds, hearing aid shells, and diagnostic tools. These plastic materials enable the integration of technology in tele-audiology devices, ensuring accurate sound transmission, comfortable fit, and overall functionality.

- Q:Can medical plastics be used for long-term medical implants?

- Yes, medical plastics can be used for long-term medical implants. Medical-grade plastics such as polyethylene, polyurethane, and silicone have been successfully used in various long-term implantable devices such as joint replacements, pacemakers, and artificial heart valves. These plastics are biocompatible, durable, and resistant to degradation, making them suitable for long-term use within the human body. However, thorough testing and regulatory approvals are essential to ensure the safety and efficacy of such implants.

- Q:How does medical plastic contribute to the development of remote monitoring devices?

- Medical plastic plays a crucial role in the development of remote monitoring devices by providing the necessary properties and characteristics required for their functionality. It offers a lightweight and durable material that can withstand various environmental conditions and sterilization processes. Medical plastics also enable the manufacturing of complex and intricate designs, allowing for the integration of sensors, electronic components, and communication technologies within the devices. Furthermore, medical plastics are biocompatible, reducing the risk of adverse reactions when in contact with the human body. Overall, medical plastic facilitates the advancement of remote monitoring devices by providing the essential features needed for their reliability, performance, and patient comfort.

- Q:What are the considerations for designing medical plastic parts for injection molding?

- When designing medical plastic parts for injection molding, several considerations need to be taken into account. First and foremost is the material selection, as the plastic used must be biocompatible, able to withstand sterilization processes, and meet regulatory standards. Additionally, the design should incorporate features that promote ease of moldability, such as uniform wall thickness, adequate draft angles, and minimal undercuts. Part functionality, durability, and assembly requirements must also be considered to ensure the final product meets the intended purpose and can be easily manufactured and assembled. Finally, factors like cost, scalability, and sustainability should be addressed to optimize the overall design and production process.

- Q:Can medical plastics be used in syringes?

- Yes, medical plastics can be used in syringes.

- Q:How do medical plastics contribute to the field of dermatology?

- Medical plastics play a crucial role in dermatology by providing innovative solutions for various procedures and treatments. These plastics are used in the fabrication of medical devices, such as surgical instruments, wound dressings, and implants, which offer improved precision, biocompatibility, and infection control. Additionally, medical plastics are used in the production of dermatological creams, ointments, and patches, ensuring optimal drug delivery and enhanced patient comfort. Overall, medical plastics contribute to the advancement of dermatology by facilitating more effective and efficient treatments, ultimately improving patient outcomes.

- Q:How do medical plastics differ from other types of plastics?

- Medical plastics differ from other types of plastics in several ways. Firstly, medical plastics are specifically designed and manufactured to meet the strict requirements and regulations of the healthcare industry. They need to be biocompatible, meaning they do not create any harmful reactions or toxic effects when in contact with the human body. Additionally, medical plastics are often sterilizable, as they are commonly used in devices or equipment that require frequent sterilization to ensure patient safety. Medical plastics are also formulated to be resistant to chemicals, heat, and wear, as they must withstand the harsh conditions of medical procedures and treatments. Overall, the unique properties and characteristics of medical plastics make them suitable for a wide range of medical applications, ensuring the safety and effectiveness of healthcare practices.

- Q:Are there any limitations to the use of medical plastics?

- Yes, there are limitations to the use of medical plastics. Some limitations include the potential for leaching of chemicals into the body, the risk of allergic reactions or sensitivities, and the inability to withstand extreme temperatures or certain sterilization methods. Additionally, the disposal and environmental impact of medical plastics is a concern.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Correcting smell dental floss suitable for children

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords