Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

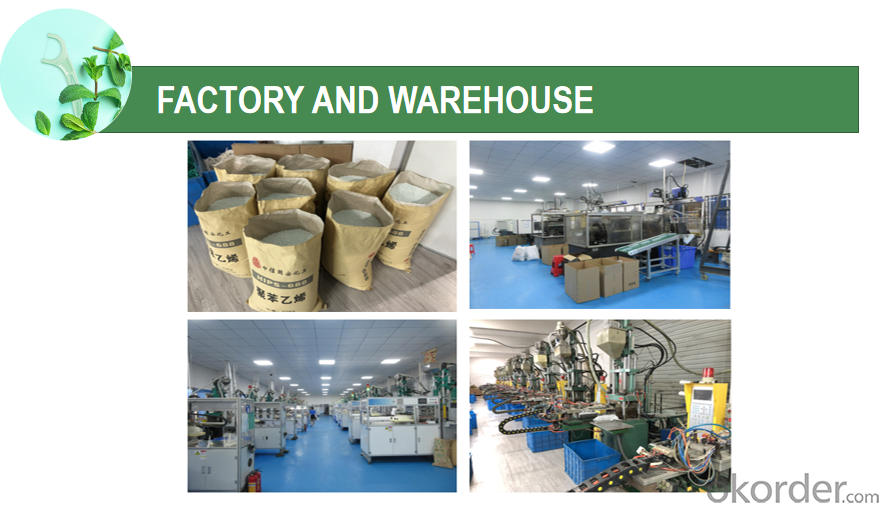

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

| Brand | OEM/Ok Floss |

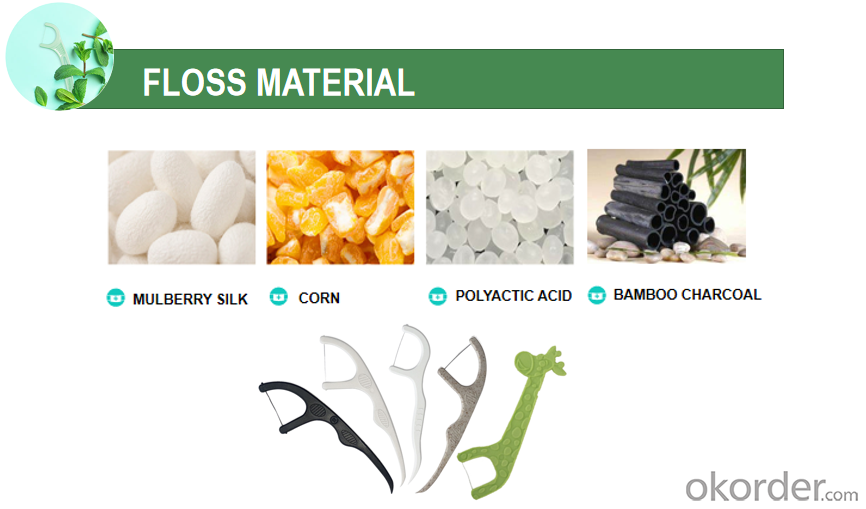

| Floss material | Charcoal /OEM |

| Floss length | 7.4*2.2cm、OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

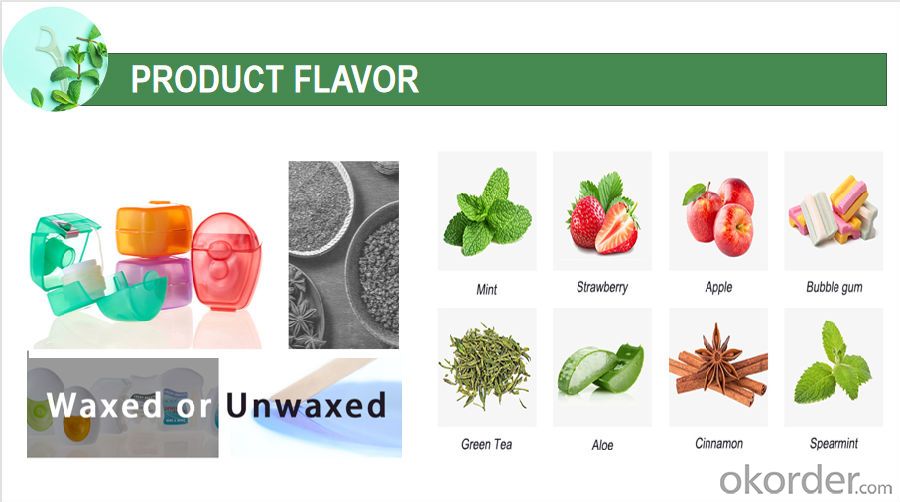

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Black |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Top quality dental floss for your business

Ok Floss help your oral care

Professional OEM/ODM provider

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

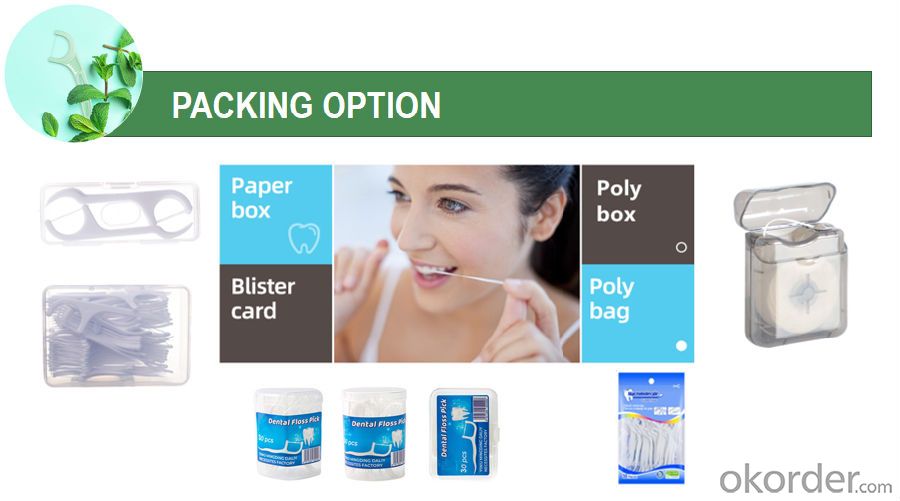

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:There is litter in the plastic pipe. How should I clean it?

- Remove obstruction by dissolving or dissolving by means of a dredge. What you need to remind is: before buying, please make sure what material the sewer pipe is, and buy the suitable pipeline dredge according to the material of the sewer pipe.

- Q:What are the advancements in self-lubricating medical plastic?

- Advancements in self-lubricating medical plastic include the development of innovative polymer formulations that possess intrinsic lubricity, reducing the need for external lubricants. These materials offer improved biocompatibility, reduced friction, and increased wear resistance, resulting in enhanced performance and longevity of medical devices. Additionally, the incorporation of nanotechnology has allowed for the creation of self-lubricating surfaces at the nanoscale, further enhancing the lubricating properties of medical plastics.

- Q:What are the advancements in shape memory medical plastic?

- Advancements in shape memory medical plastic involve the development of materials with enhanced shape memory effect, improved biocompatibility, and increased flexibility for applications in medical devices and implants. These plastics can be programmed to return to their original shape after deformation, allowing for minimally invasive procedures and improved patient outcomes. Additionally, advancements in shape memory medical plastic include the incorporation of antimicrobial properties, drug delivery capabilities, and compatibility with various sterilization methods, making them more versatile for a wide range of medical applications.

- Q:What are the most commonly used medical plastic additives?

- Some of the most commonly used medical plastic additives include plasticizers, antioxidants, UV stabilizers, lubricants, colorants, and antimicrobial agents.

- Q:How do medical plastics contribute to the development of personalized implants?

- Medical plastics play a crucial role in the development of personalized implants by providing a versatile and biocompatible material that can be tailored to each individual's specific needs. These plastics can be easily molded into complex shapes, allowing for the creation of customized implants that perfectly fit the patient's anatomy. Additionally, medical plastics are lightweight, durable, and resistant to corrosion, making them ideal for long-term implantation. By utilizing medical plastics, personalized implants can be designed to enhance patient comfort, improve surgical outcomes, and promote faster healing.

- Q:How do medical plastics contribute to the development of personalized prosthetics?

- Medical plastics play a crucial role in the development of personalized prosthetics by offering various benefits such as flexibility, durability, and biocompatibility. These plastics can be molded into complex shapes that perfectly fit an individual's unique anatomy, enhancing comfort and functionality. Additionally, medical plastics are lightweight, making prosthetics easier to wear and reducing the strain on the user. Furthermore, these materials can be colored or transparent, allowing for aesthetically pleasing designs that help boost self-confidence. Overall, medical plastics enable the creation of personalized prosthetics that greatly improve the quality of life for individuals with limb loss or impairment.

- Q:What are the considerations for using medical plastic in remote patient monitoring devices?

- There are several important considerations when using medical plastic in remote patient monitoring devices. Firstly, it is crucial to ensure that the plastic used is biocompatible and safe for long-term contact with the patient's body. This includes checking for any potential allergic reactions or adverse effects. Secondly, the plastic should be able to withstand the rigors of daily use, including resistance to cracking, breaking, or deformation. It should also be resistant to moisture, chemicals, and cleaning agents to maintain its functionality and sterility. Additionally, the plastic should be compatible with the manufacturing processes involved, such as injection molding, to ensure cost-effectiveness and scalability. Lastly, considerations should be given to the environmental impact and recyclability of the plastic used, promoting sustainability in healthcare practices. Overall, careful selection and evaluation of medical plastic are crucial to ensure the safety, durability, and effectiveness of remote patient monitoring devices.

- Q:What are the applications of medical plastic?

- Medical plastic has a wide range of applications in the healthcare industry. It is used in the manufacturing of medical devices such as syringes, catheters, surgical instruments, and implants. It also plays a vital role in creating sterile packaging for medications and medical supplies. Additionally, medical plastic is utilized in prosthetics, drug delivery systems, and various diagnostic tools. Overall, medical plastic contributes to advancements in medical technology, improves patient care, and enhances safety in healthcare procedures.

- Q:How does medical plastic contribute to tissue engineering?

- Medical plastic plays a crucial role in tissue engineering as it provides a versatile and biocompatible material for constructing scaffolds, which mimic the extracellular matrix and support cell growth. These scaffolds made from medical plastics offer a three-dimensional structure where cells can adhere, proliferate, and differentiate, facilitating tissue regeneration and repair. Additionally, medical plastics can be engineered to have specific properties like porosity, surface characteristics, and degradation rates, allowing for precise control over the tissue engineering process.

- Q:Can medical plastic be used in smart medical devices?

- Yes, medical plastic can be used in smart medical devices. Medical-grade plastics are often used in the manufacturing of various medical devices due to their biocompatibility, durability, and ability to be molded into complex shapes. These plastics can be integrated with smart technology, such as sensors, wireless connectivity, and data processing capabilities, to create smart medical devices that can monitor patients' health, deliver targeted treatments, and enhance overall healthcare outcomes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Floss Bamboo Charcoal Fiber Dental Floss Oral Care Tooth Clean Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords