Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

| Brand | OEM/Ok Floss |

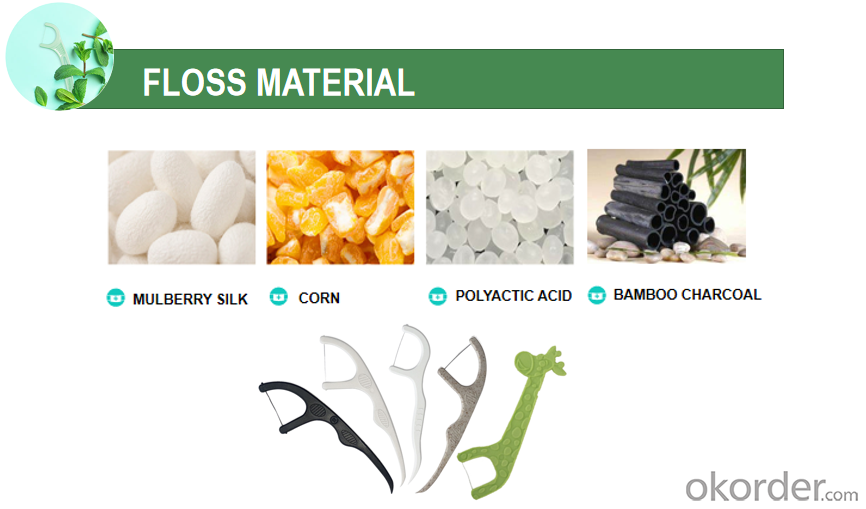

| Floss material | UHMWPE/PTFE+Straw |

| Floss length | 7.4*2.2cm/OEM |

| Wax | Import germany wax/american wax/bee wax/candelilla wax/customized wax |

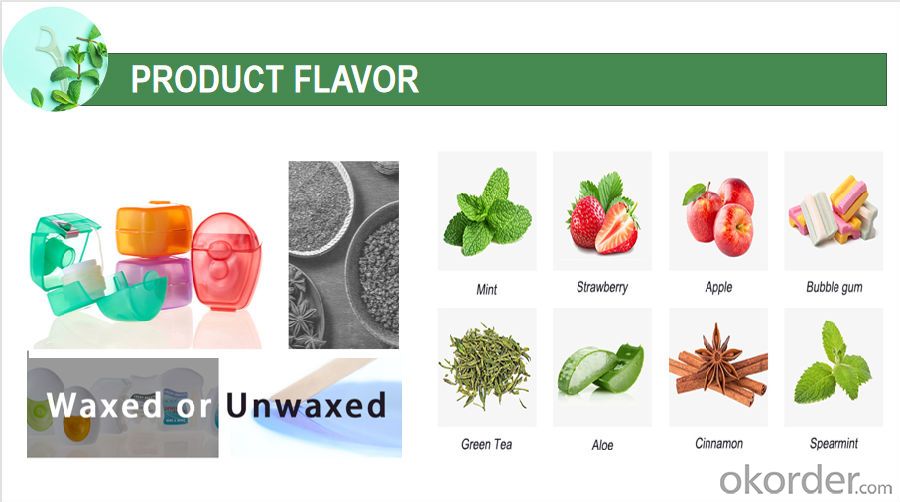

| Flavor | Mint / green tea / lemon / peach / fruit / aloe / gin |

| Color | Floss original color |

| Floss original color | Individual bulk PP bag/individual paper box/as customized |

| Applications | Family,Hotel,Travel,Supermarket |

| Delivery | By sea,By air,By express. |

| Lead time | 20-30days |

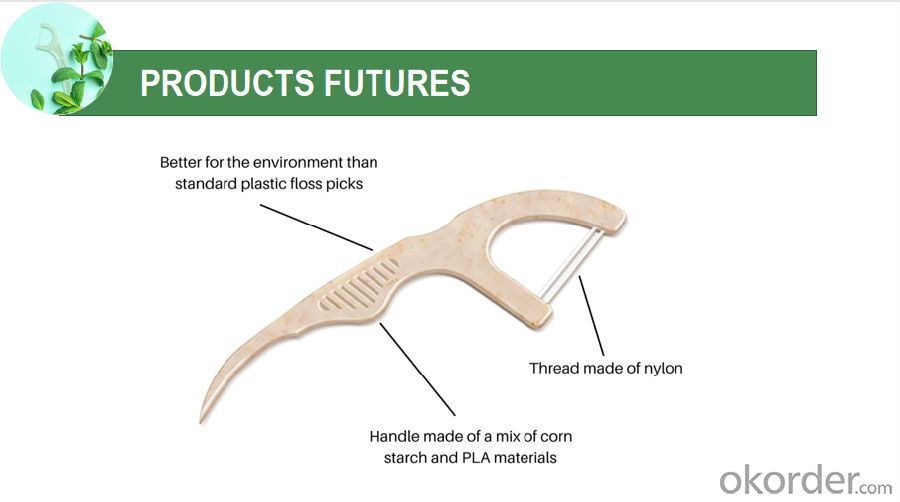

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

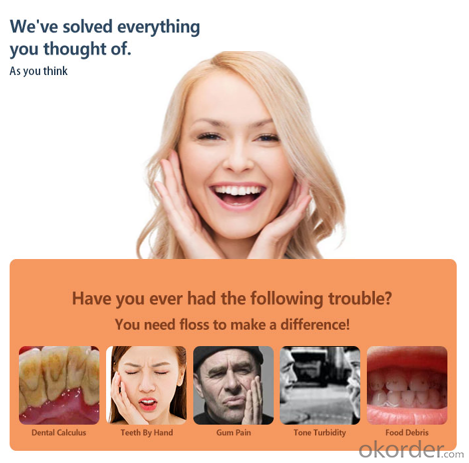

Why we need use dental floss??

Because it can reduce your chances of 60% of

adjacent dental caries and 70% of periodontal

disease.

It allows you to have a healthy tooth of your own at

the age of 80.

Flossing your teeth in the right way will remove

food particles and growing plaque from spots

where your toothbrush can’t reach, generally

between your teeth and under the gumline.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

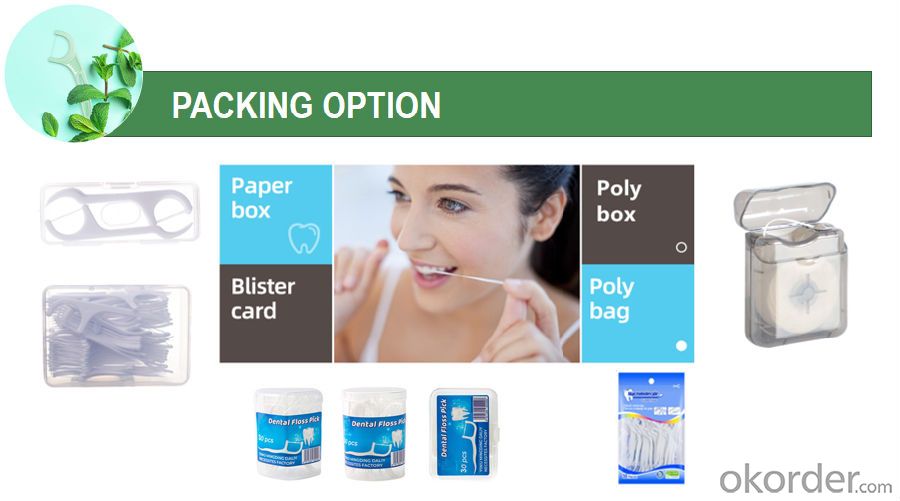

Q: Can you accept OEM make?

A: Sure.We can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:What are the factors that affect the chemical resistance of medical plastics?

- The factors that affect the chemical resistance of medical plastics include the type and concentration of chemicals, the temperature and duration of exposure, the composition and structure of the plastic material, and any additives or fillers present. Additionally, the surface finish, thickness, and porosity of the plastic can also impact its resistance to chemicals.

- Q:Can medical plastics be used in gastrointestinal applications?

- Yes, medical plastics can be used in gastrointestinal applications. They are commonly used in the manufacturing of various medical devices and equipment such as endoscopes, catheters, and stents. These plastics are preferred due to their biocompatibility, flexibility, and ability to resist corrosion and degradation when exposed to bodily fluids.

- Q:Injection molding products, down plastic powder, how to do?

- Find the source of dust, to prevent. Thoroughly clean the barrel and the injection machine

- Q:The difference between rubber and polyurethane?

- Rubber is a latex made from rubber, tree, rubber, and grass. It is made of flexible, insulating, impermeable and air. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.Rubber is made from latex, and a portion of the non - rubber contained in the latex is left in the solid rubber. In general natural rubber contains rubber hydrocarbon 92%-95%, but not rubber hydrocarbon accounts for 5%-8%. Because of the different processing methods, different habitats and even different seasons, the proportion of these ingredients may vary, but basically within the scope.Proteins can promote the vulcanization of rubber and retard aging. On the other hand, the protein has strong water absorption, can cause rubber moisture absorption, mildew, insulation degradation, protein and increase heat generation shortcomings.

- Q:How can plastic get stuck in the glass?

- Blow it for a while with a blower. After heating, the glue melts. It can be easily removed. If there are some traces of go away, can use Fengyoujing smear, will remove the relatively clean.

- Q:What are the considerations for using medical plastic in immunology applications?

- There are several important considerations when using medical plastic in immunology applications. First and foremost, the plastic must be biocompatible, meaning it does not elicit any adverse reactions or cause harm to the immune system. It should also be sterilizable, as immunology applications often require aseptic conditions. Additionally, the plastic must have excellent chemical resistance to withstand the harsh chemicals and reagents used in immunological experiments. Furthermore, the material's mechanical properties, such as flexibility and durability, should be suitable for the specific application. Lastly, considerations for cost-effectiveness and ease of manufacturing are also important factors to be taken into account.

- Q:How do medical plastics contribute to the efficiency of healthcare delivery?

- Medical plastics contribute to the efficiency of healthcare delivery in several ways. Firstly, they play a crucial role in the development of medical devices and equipment, such as syringes, catheters, and surgical instruments. These plastic materials are lightweight, durable, and can be easily sterilized, making them ideal for use in healthcare settings. Secondly, medical plastics enable the production of single-use disposable items, eliminating the need for cleaning and sterilization, therefore saving time and resources. Additionally, medical plastics provide superior performance in terms of safety, preventing the risk of infections and cross-contamination. Overall, the use of medical plastics enhances the speed, convenience, and effectiveness of healthcare delivery, ultimately benefiting both patients and healthcare professionals.

- Q:How is medical plastic tested for safety and efficacy?

- Medical plastic is tested for safety and efficacy through a combination of rigorous laboratory testing and clinical trials. The material is subjected to various physical and chemical tests to ensure its strength, durability, and resistance to chemicals. Additionally, biocompatibility tests are conducted to assess any potential adverse reactions when the plastic comes into contact with living tissue. Clinical trials involving both animals and humans are also performed to evaluate the performance and safety of the medical plastic in real-life scenarios. These comprehensive tests and trials help ensure that medical plastics meet the necessary standards and regulations before being approved for use in healthcare settings.

- Q:Which sponge is non-toxic and does not release toxic gas and can be exposed directly to the human body?

- The plastic is impure and may be recycled plastic or doped with other plastics. This plastic is not guaranteed to be safe from its source. Such as medical waste plastics and garbage collection.

- Q:What are the factors that affect the moisture resistance of medical plastics?

- There are several factors that can affect the moisture resistance of medical plastics. These include the type and quality of the plastic material used, its molecular structure and composition, the presence of additives or fillers, the processing conditions and techniques employed, and the overall design and construction of the medical device. Additionally, environmental factors such as temperature, humidity, and exposure to chemicals or sterilization methods can also impact the moisture resistance of medical plastics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dental Floss Pick Wheat Straw Eco Friendly Natural Fresh Up Floss

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 bag

- Supply Capability:

- 100000 bag/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords