Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Portable Floss roll clean environmentally friendly floss roll for house

Soft tape to ace the tight space

No break, no shred floss

Helps remove plaque between teeth

Helps prevent gingivitis between teeth

Unique handle design, makes it easy and comfortable to floss. Removes trapped food debris.

Extra bristled pick for hard to get bits,even gets behind hard-to-reach molars.

Gently slides smooth between tight teeth. Freshen breath with flavor.

Recommends you use OK flosser after every meal and snack to have a fresher, cleaner mouth. For a completely daily clean, use with a OK flosser to easily reach back teeth.

Brand OEM/Ok Floss

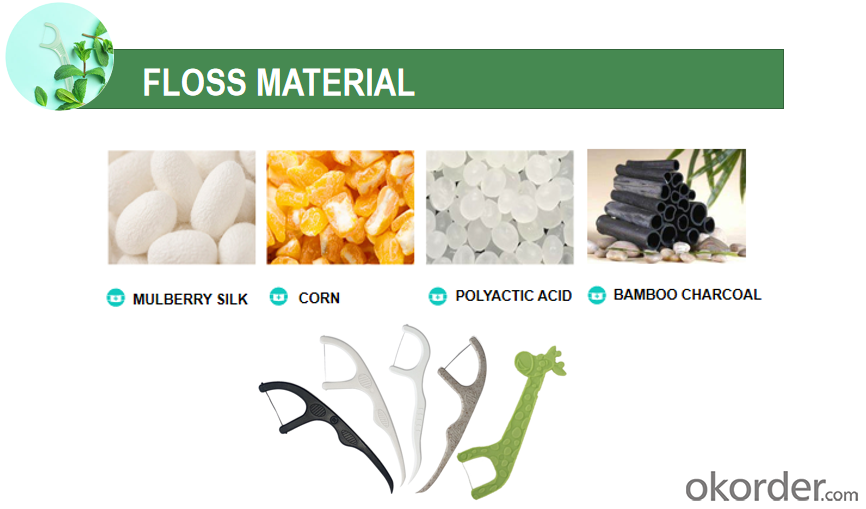

Floss materialCharcoal ,UHMWPE ,nylon

Floss length7.4*2.2cm/25-30M/OEM

WaxImport germany wax/american wax/bee wax/candelilla wax/customized wax

FlavorMint / green tea / lemon / peach / fruit / aloe / gin

ColorFloss original color

Floss original colorIndividual bulk PP bag/individual paper box/as customized

ApplicationsFamily,Hotel,Travel,Supermarket

DeliveryBy sea,By air,By express.

Lead time20-30days

Why we need use dental floss??

Because it can reduce your chances of 60% ofadjacent dental caries and 70% of periodontal disease.

It allows you to have a healthy tooth of your own at the age of 80.

Flossing your teeth in the right way will remove food particles and growing plaque from spots where your

toothbrush can’t reach, generally between your teeth and under the gumline.

Various flavors to choose:Mulberry Silk,Corn, Polyactic Acid, Bamboo Chacoal, and any flavor you want.

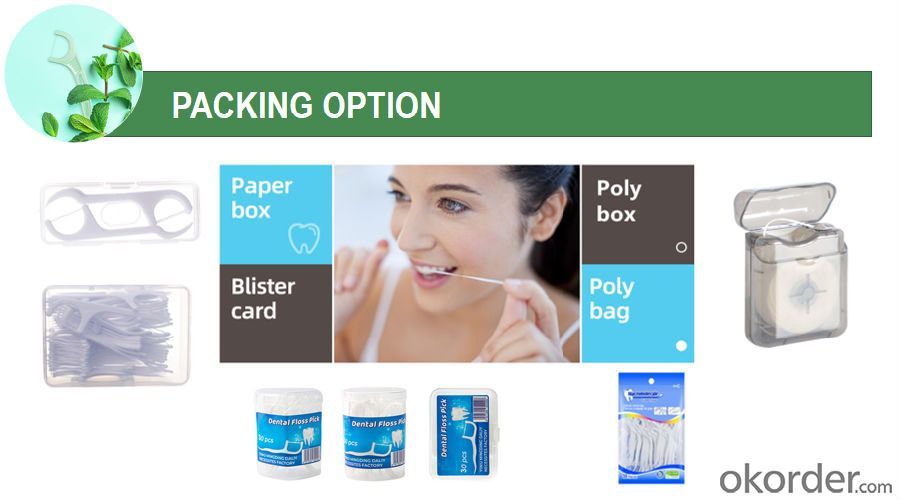

Many kinds of packaging options are available.

Suggested use

Directions for flossing: While holding the handle, gently guide the floss between your teeth using a zig-zag motion. Move floss away from the gumline in a gentle back and forth, up and down motion alongside each tooth to remove food particles and plaque. Rinse floss as needed and repeat for each tooth.

Warnings

Adult supervision recommended under age 10.

FAQ

Q: Can you accept OEMcan make your customize can make your customized brand and design blister card, inner box and master carton, and also pack as per your request.

2. Q: Where can I put my logo?

A: We can print your logo on the sticker, blister card, inner box and master carton.

3. Q: What are your MOQ?

A: Blister card packing: 10000 pcs/item.

Bulk packing: 5000 pcs/item.

4. Q: How can I get Samples?

A: Samples are free, while the shipping cost to be collected.

5. Q: What are your terms of payment?

A: 1) T/T(30% in advance, the balance by the copy of B/L).

2)For small order less than USD 3000, in order to save bank commision for both of us, we need 100% in advance.

6. Q: How long is the delivery time?

A: For the MOQ, the leading time is about 20-30 days.

- Q:What are the advancements in bioabsorbable medical plastic?

- Advancements in bioabsorbable medical plastic include the development of new polymers with enhanced strength and flexibility, improved degradation rates, and better biocompatibility. These plastics are designed to break down within the body over time, reducing the need for additional surgeries for removal. They are also being used in various medical applications such as surgical implants, drug delivery systems, and tissue engineering, offering innovative solutions for patient care and treatment.

- Q:What are the considerations for using medical plastic in wearable infusion pumps?

- When considering the use of medical plastic in wearable infusion pumps, several key factors need to be taken into account. First and foremost, the chosen plastic material must be biocompatible, meaning it does not cause any adverse reactions or harm to the patient's body when in contact with their skin or bodily fluids. Additionally, the plastic should possess good chemical resistance to ensure compatibility with various medications and fluids being administered. The material's mechanical properties, such as flexibility and durability, are crucial for the wearable nature of the device, ensuring it can withstand daily use and movement without compromising its functionality. Lastly, considerations regarding sterilization methods and the ability to maintain a sterile environment are also important factors to ensure the safety and effectiveness of the wearable infusion pump.

- Q:How are medical plastics used in imaging equipment?

- Medical plastics are used in imaging equipment in various ways. They are often used in the construction of casings and housings for imaging devices, providing durability and protection for delicate internal components. Additionally, medical plastics are utilized in the production of X-ray film and other imaging media, ensuring high image quality and clarity. They are also used in the manufacturing of components like syringes, catheters, and tubing, which are essential for procedures such as contrast imaging and angiography. Overall, medical plastics play a crucial role in enhancing the functionality, safety, and efficiency of imaging equipment in the medical field.

- Q:What are the considerations for using medical plastic in dermatological applications?

- When considering the use of medical plastic in dermatological applications, several important factors need to be taken into account. These include biocompatibility, sterilizability, durability, flexibility, and ease of fabrication. Medical plastics used in dermatological applications should be non-toxic, non-irritating, and compatible with the human skin to prevent any adverse reactions or allergies. They should also be able to withstand various sterilization methods without degradation or loss of properties. Additionally, the plastic should be durable enough to withstand repetitive use or manipulation without breaking or deforming. Flexibility is essential to ensure the plastic can conform to the contours of the skin comfortably. Lastly, ease of fabrication is crucial for efficient manufacturing and customization of dermatological devices or products.

- Q:What is the role of medical plastic in medical devices?

- Medical plastic plays a crucial role in medical devices as it provides numerous benefits such as biocompatibility, durability, flexibility, and ease of sterilization. It is used in the manufacturing of various medical devices such as syringes, catheters, implants, and surgical instruments. The use of medical plastic ensures the safety and effectiveness of these devices, allowing for better patient outcomes and improved healthcare practices.

- Q:What are the advancements in biodegradable medical plastic?

- Biodegradable medical plastics have seen significant advancements in recent years. These innovations involve the development of new materials that can break down naturally in the body, reducing the need for additional surgeries to remove implants or devices. Researchers have also made progress in enhancing the strength and durability of biodegradable plastics, making them suitable for a broader range of medical applications. Additionally, efforts are being made to improve the production process and reduce the cost of these materials, facilitating their wider adoption in healthcare settings.

- Q:What are the considerations for choosing the right medical plastic material for a specific application?

- When choosing the right medical plastic material for a specific application, there are several important considerations to keep in mind. These include the material's biocompatibility, chemical resistance, mechanical properties, sterilization compatibility, and cost. Biocompatibility ensures that the material will not cause any adverse reactions or harm to the human body. Chemical resistance is crucial to ensure the material remains stable and doesn't degrade when exposed to various chemicals or cleaning agents. Mechanical properties such as strength, flexibility, and durability are essential to meet the specific requirements of the application. Sterilization compatibility is vital to ensure the material can withstand the chosen sterilization method without compromising its integrity. Lastly, cost considerations are important to ensure the chosen material is within budget while still meeting the necessary quality and performance standards. Overall, a thorough assessment of these factors is necessary to select the most suitable medical plastic material for a specific application.

- Q:What are the considerations for using medical plastic in bioimplants?

- There are several key considerations when using medical plastic in bioimplants. Firstly, biocompatibility is crucial as the material must not cause any adverse reactions or toxicity when in contact with living tissues. Additionally, the mechanical properties of the plastic, such as strength and flexibility, need to be carefully assessed to ensure the implant can withstand the physiological demands of the body. The long-term stability and degradation rate of the plastic are important factors to determine its suitability for bioimplants. Lastly, sterilization methods and the ability of the material to resist bacterial growth are critical to prevent infections and ensure the safety of the patient.

- Q:What are the most common uses of medical plastics in occupational therapy?

- Medical plastics are commonly used in occupational therapy for various purposes such as splinting, bracing, and assistive devices. These plastics provide lightweight, durable, and customizable solutions that aid in immobilizing and supporting injured or weakened body parts, promoting healing and enhancing functional abilities.

- Q:How is medical plastic used in electrocardiography?

- Medical plastic is used in electrocardiography to make various components such as electrodes, leads, and cable connectors. These plastic materials are biocompatible, lightweight, and flexible, allowing for comfortable and reliable attachment to the patient's skin. They provide excellent electrical conductivity and insulation, ensuring accurate transmission of electrical signals from the heart to the ECG machine. Additionally, medical plastic is easy to clean and sterilize, making it suitable for repeated use in healthcare settings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Portable Floss Roll Clean Environmentally Friendly Floss Roll For House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords