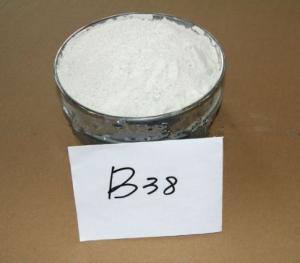

Bentonite Organic Type B38

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

Advantage Easy-to-Use,

Overall-Persistent Making Efficienty for Rheology,

Complete Spread in the condition of middle cutt

| Product Name | Organic Bentonite |

| Model Number | B38 |

| Description | As an improved assistant material of anti settling and thickening, our new organic |

| bentonite B38 was mainly applied for semi-polarity or high-polarity system, with a good | |

| efficiency of thixotropy, and anti settling.It saves cost as replacement of most traditional | |

| domestic and imported bentonite. | |

| Application | Nitrolacquer, Epoxy Resin Paint, Polyester Paint, Vinyl Ester Resin Paint, Polyester |

| Varnish, Marine Paint, Heavy Anti-Corrosive Paint, Chlorinted Rubber, Polyacrylic Acid | |

| Paint, Bituminous Paint, Base Paint, Adhesive, Printing Ink, Sealing Compound etc.. | |

| Dosage | The dosage of organic bentonite depends on the thickening level of requirement, the |

| control of sag resistance and anti-settling result for pigment etc. Normal dosage is | |

| 0.2%-3.0%, the dosage is better to be same as replacement when do the replacement, | |

| then adjust accroding to the specific requirement,normally less than traditional one. | |

| Advantage | Easy-to-Use, Overall-Persistent Making Efficienty for Rheology, Complete Spread in the |

| condition of middle cutting, Simplifying Viscosity & Adjustment after sag resistance, | |

| Good Stability of Heating, Good Stability of Storage. | |

| Physical Property | Composition - Organic Montmorillonite Ramification |

| Appearance - Super Fine Powder | |

| Diameter of Grain under Complete Spread - 1-3um | |

| Colour - Parchment (Cream) | |

| Density (g/cm3) - 1.7 | |

| Mositure Level (%) - less 3.5 | |

| Burning Disappearing (%) - less 36 |

- Q:Difference between natural sodium based bentonite and artificial sodium based bentonite

- Difference: pH value is less than 8, artificial 8 or more

- Q:What do you mean by "200 eye bentonite" in the data?

- Refers to the number of orders per square inch empty eye screen, 50 holes per square inch refers to the 50, 500 is 500, the higher the number, the more holes. In addition to said screen hole, it can be said at the same time for the screen by the particle size, the higher the number, the smaller the particle size.

- Q:How can dust be removed during the bentonite milling process?

- Shanghai ChangLei production of high pressure micro grinding special processing bentonite, barite, calcite, limestone, kaolin, marble, gypsum and hardness is less than 7, the temperature in the processing of non-metallic minerals below 6%, fineness can be adjusted between 80 and 1500, and the machine mainly consists of the host, blower super fineness analysis machine.

- Q:I am a water-based coating. How can inorganic bentonite be used?.

- Pre accession, and after joining can be, it is best to do their own experiments to determine.Na based bentonite 200 mesh, 650 yuan / ton.

- Q:Waterproof characteristics of bentonite waterproof blanket

- Easy construction and short construction periodCompared with other waterproof materials, the construction is relatively simple, without heating and pasting. Only with bentonite powder and nails, gaskets and other connections and fixed. No special inspection is required after construction, and it is easy to repair if water proof defects are found. GCL is the shortest construction period in existing waterproof materials.Unaffected by the temperature

- Q:Can organic bentonite be added to base oil?

- Additives and fillers designed to improve some characteristics of greases are added. Grease can be attached to the vertical table... At room temperature under general grease with medium viscosity and high viscosity oil lubricating oil as base oil, there are also some to meet in the harsh by surfactant (e.g. two methyl eighteen alkyl benzyl ammonium chloride and amide) after the treatment of organic bentonite thickening. Or high viscosity oil is made, suitable for truck chassis, driving rudder, universal joint, water pump, hub and bearing lubrication.

- Q:Montmorillonite desiccant and lime desiccant which is good, and their chemical composition is what?,

- Montmorillonite desiccant is made of YISHION natural montmorillonite as raw material, dried and activated, without any additives and soluble substances. It is a pollution-free, non-toxic and pollution-free green environmental protection product

- Q:Production of sodium based bentonite

- In the drying process, the heat exchange type hot blast stove is used as a drying energy source, and the high temperature purified flue gas generated by the hot blast stove is fully contacted with the sodium base bentonite in the three channel rotary drier to achieve the purpose of removing moisture. After drying the material in the cyclone in the wind from amenorrhea.

- Q:What is the rate of making bentonite?

- One of the main purposes of bentonite is used as drilling fluid materials. Mudmaking rate is one of the main indicators to measure the slurry properties of bentonite, the unit weight of the bentonite can be formulated with the apparent viscosity of suspension liquid product 15mPa - S (m3/t).

- Q:Is expansive soil bentonite? Can it be used for piling and pulping?

- I can't say clearly about the question of whether or not it can be used for piling and pulping. Generally speaking, expansive soil belongs to clay, and has the property of softening with water and certain lubrication. People think it can be used as pulping.

We focus on developing and utilizing bentonite products at high grade. Based on the traditional bentonite clay, we have developed many new and classic organic bentonite products for multiple fields, such as painting, coating, ink, waterproof, drilling, etc.

Our organic bentonite is mainly used in industrial fields, and is used for adding system adhesive, protecting sedimentation and controlling liquid sagging.

We are looking forward to achieving good cooperation with partners at home and abroad and creating a glorious future.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 2010 |

| Annual Output Value | US$10 Million - US$50 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai,NingBo |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Bentonite Organic Type B38

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 15 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords