Aluminum Profile 6063 t5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminum Profile 6063 t5 Aluminum Extruded Profiles Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6063 t5 Aluminum Extruded Profiles :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

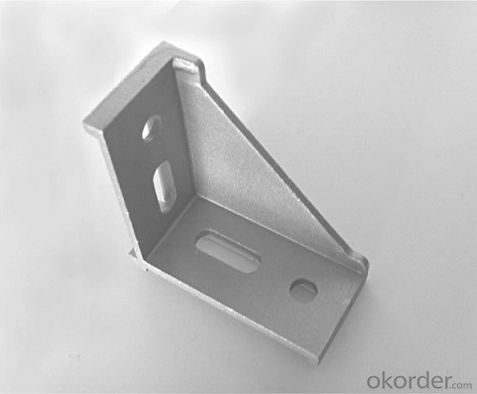

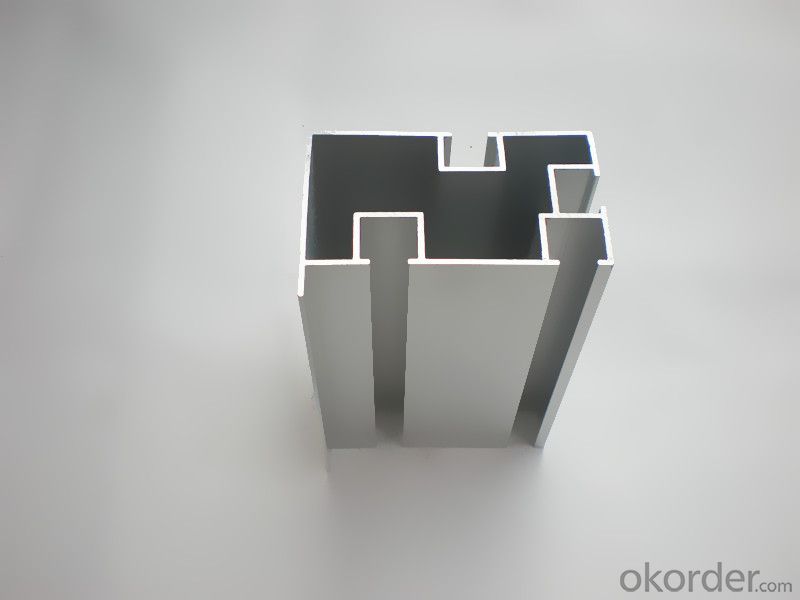

3.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Images:

4.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Shenzhen aluminum profile manufacturers which good?

- How to choose the industrial aluminum profiles, this problem for the just contact with industrial aluminum profile friends, is really a serious problem to consider.That selection of industrial aluminum manufacturers is not good, money, goods is not good, he can give you redo is OK, but also take time; meet industrial aluminum manufacturers some black, and you may be wrangling, that egg pain.

- Q:Can aluminum profiles be used in solar mounting systems?

- Yes, aluminum profiles can be used in solar mounting systems. Aluminum is a popular choice for solar mounting systems due to its lightweight, durability, and corrosion resistance properties. It is also easy to fabricate and install, making it an ideal material for constructing solar panel frames, rails, and supports. Additionally, aluminum profiles can be easily recycled, making them an environmentally friendly choice for solar mounting systems. Overall, aluminum profiles are a reliable and efficient option for solar mounting systems.

- Q:Are aluminum profiles suitable for earthquake-resistant structures?

- Yes, aluminum profiles can be suitable for earthquake-resistant structures. Aluminum is lightweight and flexible, allowing it to absorb and dissipate the energy generated during an earthquake. Additionally, aluminum profiles have excellent strength-to-weight ratio and corrosion resistance, making them a suitable choice for seismic applications. However, the design and engineering of the structure, along with appropriate reinforcement, are crucial factors in ensuring its earthquake resistance.

- Q:A curtain wall predecessors?For example, under the transverse frame section, with 6m specifications, why should the material processing and minus 50mm? Insert plate, plate to cut 100mm head? What is the law?

- As you said the core insert to reduce 100mm plate plate, this is because the length of processing of these parts is relatively small, some ten centimeters in length, the process if you use a single head saw or double saw large mechanical cutting, base metal processing machinery in a relatively short time finally can not be cut, that is to say the last 100mm~150mm machine cannot continue cutting, it is useless.

- Q:Can aluminum profiles be used in modular construction systems?

- Modular construction systems readily employ aluminum profiles due to their lightweight and durable nature. These profiles, constructed from aluminum, are highly suitable for modular construction purposes. Not only do they confer structural stability, but they can also be easily manipulated into different shapes and sizes to meet specific design needs. Additionally, aluminum profiles exhibit exceptional resistance to corrosion, rendering them highly suitable for both indoor and outdoor applications. Furthermore, their recyclability makes them a sustainable choice for modular construction systems, aligning with environmentally-friendly practices. On the whole, aluminum profiles present a plethora of advantages in terms of strength, flexibility, and sustainability, thus solidifying their popularity within the world of modular construction.

- Q:Are there any fire safety considerations when using aluminum profiles?

- Yes, there are fire safety considerations when using aluminum profiles. Although aluminum itself is not combustible, it can still contribute to the spread and intensity of a fire. Aluminum profiles, especially when used in construction or industrial applications, can act as fuel for a fire and potentially increase its severity. One important consideration is the fire rating of the aluminum profiles. Fire ratings indicate the length of time a material can withstand exposure to fire before it fails. It is crucial to select aluminum profiles with appropriate fire ratings that align with the specific requirements of the application. This ensures that the profiles can delay the spread of fire, providing valuable time for evacuation and firefighting efforts. Another consideration is the use of appropriate insulation materials. Aluminum profiles are often used in building facades, curtain walls, and other structural applications. In such cases, it is important to ensure that the insulation materials used with the aluminum profiles are fire-resistant. This helps prevent the fire from spreading through the building envelope and reduces the risk of structural failure. Additionally, fire safety measures should be implemented during the installation process. Proper firestopping techniques should be employed to seal any gaps or penetrations around the aluminum profiles. This helps prevent the passage of flames, smoke, and hot gases from one compartment to another, limiting the fire's spread. Regular maintenance and inspection of the aluminum profiles are also essential for fire safety. Any damage or deterioration should be promptly addressed to prevent potential fire hazards. Additionally, proper fire detection and suppression systems should be in place to detect and control fires in a timely manner. Overall, while aluminum profiles themselves may not be combustible, it is important to consider various fire safety measures when using them in construction or industrial applications. By selecting appropriate fire-rated profiles, using fire-resistant insulation materials, implementing proper installation techniques, and maintaining regular inspections, the risk of fire can be minimized, ensuring the safety of occupants and property.

- Q:Can aluminum profiles be used in interior design applications?

- Certainly, aluminum profiles are a fantastic option for incorporating into interior design projects. Thanks to its versatility and durability, aluminum offers countless design possibilities. In fact, it can be utilized to fabricate a wide range of features, including doors, windows, partitions, furniture frames, lighting fixtures, and decorative accents within interior spaces. Aluminum profiles come in diverse shapes, sizes, and finishes, allowing for customization and adaptability in design. They can be anodized, powder-coated, or painted to match any desired color scheme. Moreover, aluminum profiles can be effortlessly shaped and manipulated to produce unique and intricate designs. One notable advantage of utilizing aluminum profiles in interior design is their lightweight composition, making them easy to install and handle. Additionally, aluminum is resistant to corrosion, enabling it to withstand moisture and humidity in areas such as bathrooms and kitchens. Furthermore, aluminum profiles offer long-lasting durability, as they resist warping, cracking, and fading. Consequently, they are an ideal choice for high-traffic areas or commercial spaces that require frequent use. Regarding aesthetics, aluminum profiles can provide a contemporary and streamlined appearance, elevating the overall design of a space. They can be paired with other materials like glass or wood to achieve a modern and sophisticated look. Furthermore, aluminum is an environmentally friendly and sustainable material. It can be fully recycled, thereby contributing to a reduced carbon footprint and a more sustainable approach to design. In conclusion, aluminum profiles are an excellent option for various interior design applications. Their versatility, durability, lightweight composition, and aesthetic appeal make them a popular choice for designers seeking functional and visually appealing solutions for interior spaces.

- Q:Can aluminum profiles be used for modular storage systems?

- Yes, aluminum profiles can be used for modular storage systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including storage and shelving systems. Its versatility allows for easy customization and the ability to create modular units that can be easily assembled, disassembled, and reconfigured as needed. Additionally, aluminum profiles provide a sleek and modern aesthetic to storage systems.

- Q:Can aluminum profiles be used for electrical bus ducts?

- Yes, aluminum profiles can be used for electrical bus ducts. Aluminum is a commonly used material in the electrical industry due to its excellent conductivity and lightweight properties. It offers great electrical conductivity, which is crucial for transmitting electrical power efficiently. Additionally, aluminum profiles are durable, corrosion-resistant, and can withstand high temperatures, making them suitable for various industrial applications. However, it's important to consider the specific requirements and regulations of the project to ensure the aluminum profiles meet the necessary electrical and safety standards.

- Q:High compartment aluminum profiles are generally divided into several specifications, what are the attributes?

- Aluminum alloy profiles are basically no GB non-standard, but the state has special specifications for architectural aluminum profiles, mainly on the thickness of the material, materials and so on.Each aluminum alloy profiles manufacturing enterprises are basically similar products, but in specific structure of the discrepancy. But such as the more general series, such as GB 50, 868, and 90, these are basically the same.The 80 series and the 60 series refer to the aluminium alloy profiles with widths of 80 mm and 60 mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Profile 6063 t5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords