All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

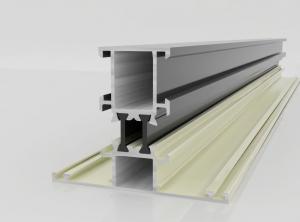

What are the key design considerations when creating complex shapes and structures using aluminum profiles?

When creating complex shapes and structures using aluminum profiles, there are several key design considerations to keep in mind. Firstly, it is important to consider the strength and load-bearing capacity of the aluminum profiles. This involves selecting the appropriate profile size, thickness, and alloy to ensure it can withstand the intended loads and stresses.

Another consideration is the joining and assembly methods. Aluminum profiles can be connected using various techniques such as welding, bolting, or adhesive bonding. The choice of joining method should be based on the specific application requirements, such as the need for flexibility, strength, or ease of disassembly.

Furthermore, the design should also take into account the desired aesthetics and surface finish. Aluminum profiles can be finished in various ways, such as powder coating, anodizing, or painting, to enhance their appearance and protect against corrosion.

Lastly, the design should consider the feasibility of manufacturing and assembly. Complex shapes and structures may require specialized fabrication techniques or assembly processes. It is crucial to ensure that the design can be efficiently manufactured and assembled without compromising the overall quality and functionality of the final product.

How do you calculate the energy savings associated with using aluminum profiles in buildings?

To calculate the energy savings associated with using aluminum profiles in buildings, you would need to compare the energy consumption of buildings using aluminum profiles to those using alternative materials. By analyzing factors such as insulation properties, thermal conductivity, and energy efficiency, you can estimate the difference in energy usage. Additionally, considering the lifespan and maintenance requirements of aluminum profiles can provide a comprehensive assessment of the energy savings.

What are the weight considerations for aluminum profiles in aerospace applications?

Weight considerations for aluminum profiles in aerospace applications are crucial as they directly impact the overall weight of the aircraft. Aluminum profiles are preferred due to their lightweight nature, which allows for improved fuel efficiency and increased payload capacity. Additionally, lighter profiles contribute to better maneuverability and performance of the aircraft. Therefore, ensuring that the weight of aluminum profiles is minimized without compromising structural integrity is of utmost importance in aerospace applications.

Wholesale Aluminum Profiles from supplier in Nicaragua

We are a Aluminum Profiles supplier serving the Nicaragua, mainly engaged in the sale, quotation, and technical support services of various Aluminum Profiles products in the Nicaragua region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Profiles procurement services in the Nicaragua. Not only do we have a wide range of Aluminum Profiles products, but after years of market development in the Nicaragua, we can also provide valuable experience for your projects.