All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you ensure the safety and regulatory compliance of aluminum profile-based solutions in infrastructure and construction projects?

Ensuring the safety and regulatory compliance of aluminum profile-based solutions in infrastructure and construction projects involves several key steps.

Firstly, thorough research and understanding of the applicable building codes, regulations, and industry standards is crucial. This includes knowledge of structural requirements, fire safety regulations, and relevant environmental and sustainability standards.

Secondly, working closely with reputable suppliers and manufacturers who adhere to high-quality standards is essential. This ensures that the aluminum profiles used in the projects meet or exceed the necessary safety and regulatory requirements. Conducting regular quality checks and audits on the suppliers' manufacturing processes is important to ensure consistency and adherence to standards.

Thirdly, engaging with experienced engineers and architects who have expertise in designing and specifying aluminum profile-based solutions is vital. They can ensure that the designs and installations comply with the necessary safety measures and regulations.

Furthermore, periodic inspections and testing during the construction phase help identify any potential issues or deviations from the intended design. This allows for timely corrections and ensures compliance with safety and regulatory requirements.

Lastly, ongoing maintenance and monitoring of the aluminum profile-based solutions are necessary to ensure their continued safety and compliance. This includes regular inspections, maintenance activities, and addressing any potential issues promptly.

Overall, a comprehensive approach that includes thorough research, reliable suppliers, experienced professionals, regular inspections, and ongoing maintenance is crucial to ensure the safety and regulatory compliance of aluminum profile-based solutions in infrastructure and construction projects.

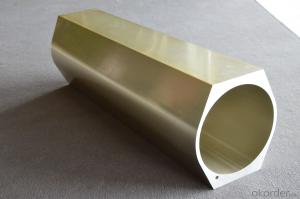

What are the measures taken to enhance the corrosion resistance of aluminum profiles in challenging marine environments?

There are several measures taken to enhance the corrosion resistance of aluminum profiles in challenging marine environments. One common approach is the use of protective coatings such as anodizing or powder coating, which create a barrier between the aluminum and the corrosive elements in the marine environment. Additionally, the use of alloys with higher levels of corrosion resistance, such as marine-grade aluminum, can help improve the durability of the profiles. Regular maintenance and cleaning, along with the use of stainless steel fasteners and gaskets, are also important measures to prevent corrosion in marine environments.

How do the environmental impacts of aluminum profiles compare to other materials like plastic or wood?

The environmental impacts of aluminum profiles are generally lower compared to materials like plastic or wood. Aluminum is a highly recyclable material, meaning it can be reused without significant degradation in quality. It requires less energy to recycle aluminum compared to producing it from raw materials, resulting in reduced carbon emissions. Additionally, aluminum is lightweight, durable, and corrosion-resistant, making it a sustainable choice for various applications. In contrast, plastic and wood often have higher carbon footprints due to their production processes, limited recyclability, and potential for deforestation. However, it is important to consider specific product characteristics and life cycle assessments to accurately determine the environmental impacts of each material.

What are the electrical conductivity properties of aluminum profiles?

Aluminum profiles have excellent electrical conductivity properties. Aluminum is a good conductor of electricity, with a conductivity of approximately 61% of the International Annealed Copper Standard (IACS). This makes aluminum profiles suitable for various electrical applications, such as power transmission lines, electrical wiring, and electrical components.

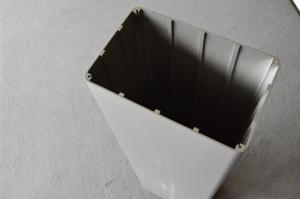

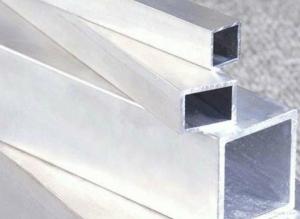

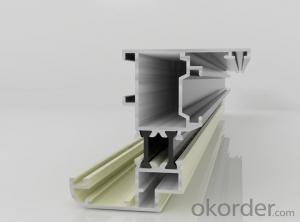

Wholesale Aluminum Profiles from supplier in Bhutan

We understand the unique requirements of the Bhutan market and strive to provide tailored solutions to meet your specific needs. Whether you are involved in construction, engineering, or any other industry that requires Aluminum Profiles, we have the expertise to assist you.

Our team of experienced professionals is dedicated to offering excellent customer service. We can provide you with accurate sales and quotations, ensuring that you receive competitive pricing for your Aluminum Profiles requirements. Additionally, our technical support services are available to address any queries or concerns you may have regarding the use and installation of our products.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers. This allows us to offer a comprehensive range of Aluminum Profiles products, ensuring that you have access to the highest quality materials for your projects in Bhutan.

With our years of experience in the Bhutan market, we have developed strong relationships with local suppliers and contractors. This enables us to provide efficient and reliable procurement services, ensuring that your Aluminum Profiles are delivered on time and in accordance with your specifications.

Partnering with us means gaining a valuable ally for your projects in Bhutan. We are committed to delivering exceptional products and services, and we look forward to the opportunity to work with you. Contact us today to discuss your Aluminum Profiles requirements and let us be your trusted supplier in Bhutan.

Our team of experienced professionals is dedicated to offering excellent customer service. We can provide you with accurate sales and quotations, ensuring that you receive competitive pricing for your Aluminum Profiles requirements. Additionally, our technical support services are available to address any queries or concerns you may have regarding the use and installation of our products.

Being a subsidiary platform of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and manufacturers. This allows us to offer a comprehensive range of Aluminum Profiles products, ensuring that you have access to the highest quality materials for your projects in Bhutan.

With our years of experience in the Bhutan market, we have developed strong relationships with local suppliers and contractors. This enables us to provide efficient and reliable procurement services, ensuring that your Aluminum Profiles are delivered on time and in accordance with your specifications.

Partnering with us means gaining a valuable ally for your projects in Bhutan. We are committed to delivering exceptional products and services, and we look forward to the opportunity to work with you. Contact us today to discuss your Aluminum Profiles requirements and let us be your trusted supplier in Bhutan.