All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

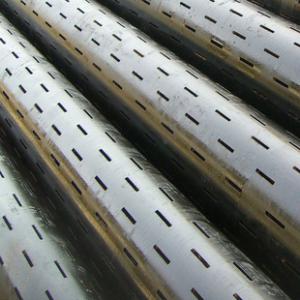

How do hollow steel tubes contribute to sustainable energy production and distribution?

Hollow steel tubes play a crucial role in sustainable energy production and distribution as they are commonly used in the construction of wind turbines and solar thermal systems. In wind turbines, these tubes are used to create the tower structure, providing stability and support for the rotating blades. Similarly, in solar thermal systems, they are employed in the construction of parabolic troughs or receiver tubes, which capture sunlight and convert it into thermal energy. The use of hollow steel tubes ensures durability and resistance to harsh weather conditions, enhancing the longevity and efficiency of these renewable energy systems. Furthermore, steel is a highly recyclable material, contributing to the overall sustainability of the energy sector.

Can hollow steel tubes be used for electrical conduits?

Yes, hollow steel tubes can be used as electrical conduits. They are commonly utilized due to their durability, high resistance to corrosion, and ability to protect electrical wires and cables from damage.

What are the different load distribution methods for hollow steel tubes?

Some of the different load distribution methods for hollow steel tubes include axial loading, bending, torsion, and combined loading. Axial loading refers to the application of a load along the longitudinal axis of the tube. Bending involves the application of a load that causes the tube to bend or deform. Torsion refers to the twisting of the tube due to applied torque. Combined loading occurs when multiple types of loads are applied simultaneously, such as axial loading with bending or torsion.

How do hollow steel tubes perform in terms of resistance to bending?

Hollow steel tubes perform excellently in terms of resistance to bending due to their structural design. The hollow shape provides increased strength and stability, making them highly resistant to bending forces compared to solid steel bars or other materials.

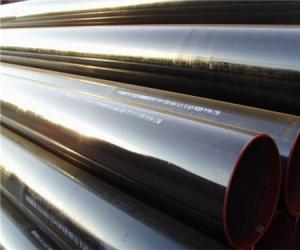

What are the different surface coatings available for hollow steel tubes?

There are several different surface coatings available for hollow steel tubes, including galvanized coatings, epoxy coatings, powder coatings, and paint coatings. These coatings serve to protect the steel from corrosion, enhance its appearance, and improve its durability in various environments.

Wholesale Hollow Steel Tubes from supplier in Bhutan

Whether you are in need of Hollow Steel Tubes for construction, infrastructure, or other industrial applications, we have the knowledge and resources to meet your requirements. Our team of experts is dedicated to providing personalized solutions and ensuring the highest quality products are delivered to your doorstep.

We understand the unique challenges of the Bhutan market and have established strong relationships with local suppliers and manufacturers. This allows us to offer competitive prices and reliable delivery times for all your Hollow Steel Tubes needs.

In addition to our sales and procurement services, we also provide comprehensive technical support. Our experienced engineers are available to assist with product selection, application guidance, and troubleshooting. We strive to be your trusted partner throughout the entire project lifecycle.

As a subsidiary of CNBM, we adhere to the highest standards of quality and customer service. Our commitment to excellence has earned us a solid reputation in the industry, and we are proud to be the preferred supplier of Hollow Steel Tubes in Bhutan.

Contact us today to discuss your specific requirements and let us show you how we can add value to your projects with our extensive range of Hollow Steel Tubes and exceptional services.

We understand the unique challenges of the Bhutan market and have established strong relationships with local suppliers and manufacturers. This allows us to offer competitive prices and reliable delivery times for all your Hollow Steel Tubes needs.

In addition to our sales and procurement services, we also provide comprehensive technical support. Our experienced engineers are available to assist with product selection, application guidance, and troubleshooting. We strive to be your trusted partner throughout the entire project lifecycle.

As a subsidiary of CNBM, we adhere to the highest standards of quality and customer service. Our commitment to excellence has earned us a solid reputation in the industry, and we are proud to be the preferred supplier of Hollow Steel Tubes in Bhutan.

Contact us today to discuss your specific requirements and let us show you how we can add value to your projects with our extensive range of Hollow Steel Tubes and exceptional services.