All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

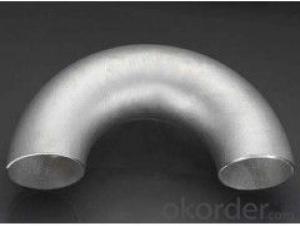

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

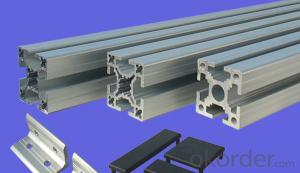

What are the key mechanical properties of aluminum profiles and how are they tested?

The key mechanical properties of aluminum profiles include tensile strength, yield strength, ductility, hardness, and impact resistance. These properties determine the material's ability to withstand external forces and deformation.

To test these properties, various methods are employed. Tensile strength and yield strength are typically evaluated through tensile testing, where a sample is subjected to gradually increasing tension until it fractures. Ductility is assessed by measuring the elongation or reduction in cross-sectional area during the tensile test.

Hardness is commonly measured using the Rockwell or Brinell hardness tests, which determine the material's resistance to indentation from a standardized indenter. Impact resistance is evaluated through impact testing, where a sample is subjected to a sudden blow or impact, and the absorbed energy is measured.

Other mechanical tests, such as bending, compression, and fatigue tests, may also be conducted to assess specific properties and determine the material's suitability for various applications. Overall, these mechanical tests ensure that aluminum profiles meet the required standards and exhibit the desired mechanical performance.

What are the methods for recycling and reusing aluminum profiles removed from decommissioned structures?

There are several methods for recycling and reusing aluminum profiles removed from decommissioned structures. One common method is melting down the aluminum profiles to create new aluminum products. This involves heating the profiles to a high temperature until they melt, and then casting the molten aluminum into molds to create new shapes and products. Another method is to mechanically process the aluminum profiles by shredding or crushing them into smaller pieces, which can then be used as raw material for manufacturing new aluminum products. Additionally, the aluminum profiles can be repurposed and reused in their current form, either in other construction projects or for various industrial applications.

How do you cut and shape aluminum profiles for specific designs and requirements?

To cut and shape aluminum profiles for specific designs and requirements, several methods can be used. One common approach is using a saw to cut the profiles to the desired length. For shaping, techniques like bending, drilling, or milling can be employed. Additionally, specialized tools like routers or laser cutters can be used for more intricate designs. It is important to ensure proper safety measures are followed and to consult professional guidance or reference materials for specific techniques based on the complexity of the profiles and designs.

What are the benefits of using aluminum profiles in the aerospace industry?

There are several benefits of using aluminum profiles in the aerospace industry. Firstly, aluminum profiles are lightweight, which helps to reduce the overall weight of the aircraft, resulting in improved fuel efficiency and reduced emissions. Additionally, aluminum profiles offer high strength-to-weight ratio, making them ideal for structural components of aircraft, ensuring safety and reliability. Moreover, aluminum profiles have excellent corrosion resistance, enhancing the longevity of the aircraft and reducing maintenance costs. Lastly, aluminum profiles are easily recyclable, promoting sustainability and reducing environmental impact in the aerospace industry.

Wholesale Aluminum Profiles from supplier in Djibouti

We are a Aluminum Profiles supplier serving the Djibouti, mainly engaged in the sale, quotation, and technical support services of various Aluminum Profiles products in the Djibouti region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Profiles procurement services in the Djibouti. Not only do we have a wide range of Aluminum Profiles products, but after years of market development in the Djibouti, we can also provide valuable experience for your projects.