All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

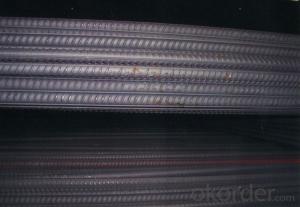

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the environmental benefits of reusing steel rebars from deconstructed structures in new projects?

There are several environmental benefits of reusing steel rebars from deconstructed structures in new projects. Firstly, reusing steel rebars reduces the need for new production, which in turn reduces the energy consumption and greenhouse gas emissions associated with manufacturing new steel rebars. This helps to conserve natural resources and mitigate the environmental impact of steel production. Additionally, reusing steel rebars reduces the amount of construction waste that would otherwise end up in landfills, contributing to the problem of waste management. By promoting the circular economy and extending the lifespan of steel rebars, we can minimize the environmental footprint of construction projects and promote sustainability in the industry.

How are steel rebars used in the construction of roads and highways?

Steel rebars are used in the construction of roads and highways to provide reinforcement and strength to the concrete. They are typically placed within the concrete pavement or structures to increase their load carrying capacity and resist cracking or deformation under heavy traffic or environmental conditions. The rebars act as a framework that helps distribute the load evenly and prevent the concrete from breaking apart, ensuring the durability and longevity of the road or highway.

How are steel rebars used in the construction of transportation infrastructure, including bridges and highways?

Steel rebars are commonly used in the construction of transportation infrastructure, such as bridges and highways, to reinforce concrete structures. They are inserted into the concrete structures, providing tensile strength and preventing cracking or failure under heavy loads. The rebars help to enhance the overall durability and structural integrity of the transportation infrastructure, ensuring long-lasting and safe usage.

What is the impact of overloading on steel-reinforced concrete structures?

Overloading on steel-reinforced concrete structures can have significant negative impacts. It can lead to an increased risk of structural failure, resulting in potential collapse or damage to the structure. Overloading can cause the concrete to crack or spall, compromising its integrity and reducing its load-bearing capacity. Additionally, excessive loads can cause the steel reinforcement to yield or even fracture, further compromising the structure's strength and stability. Therefore, it is crucial to adhere to the recommended design loads and avoid overloading to ensure the safety and longevity of steel-reinforced concrete structures.

Wholesale Steel Rebars from supplier in Djibouti

With our extensive experience and expertise in the Steel Rebars industry, we are confident in our ability to meet all your requirements in Djibouti. Our range of Steel Rebars products is carefully selected to ensure the highest quality and reliability. Whether you need standard or customized solutions, we have the capabilities to meet your specific needs.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry-leading technologies. This allows us to provide you with comprehensive services, from procurement to delivery. Our team of experts is dedicated to understanding your unique requirements and providing tailored solutions that meet your expectations.

When you choose us as your supplier, you can trust in our commitment to excellence and customer satisfaction. We strive to deliver top-notch services and products that adhere to the highest industry standards. Our team is readily available to assist you with any sales inquiries, provide competitive quotations, and offer technical support whenever needed.

Whether you are involved in construction projects, infrastructure development, or any other industry that requires Steel Rebars, we are here to serve you. Contact us today to discuss your Steel Rebars needs in Djibouti, and let us show you why we are the preferred choice for many businesses in the market.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry-leading technologies. This allows us to provide you with comprehensive services, from procurement to delivery. Our team of experts is dedicated to understanding your unique requirements and providing tailored solutions that meet your expectations.

When you choose us as your supplier, you can trust in our commitment to excellence and customer satisfaction. We strive to deliver top-notch services and products that adhere to the highest industry standards. Our team is readily available to assist you with any sales inquiries, provide competitive quotations, and offer technical support whenever needed.

Whether you are involved in construction projects, infrastructure development, or any other industry that requires Steel Rebars, we are here to serve you. Contact us today to discuss your Steel Rebars needs in Djibouti, and let us show you why we are the preferred choice for many businesses in the market.