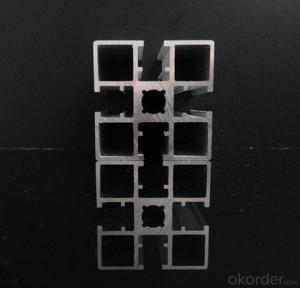

Aluminum Extruded Tubing

Aluminum Extruded Tubing Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For SaleAluminum Extruded Tubing Supplier & Manufacturer from China

Okorder.com is a professional Aluminum Extruded Tubing supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aluminum Extruded Tubing firm in China.Hot Products

FAQ

- Yes, aluminum profiles can be used for balustrades. Aluminum is a lightweight and durable material that is commonly used in construction for its strength and resistance to corrosion. It is also easy to shape and work with, making it ideal for creating various designs and styles for balustrades. Additionally, aluminum profiles can be powder coated or anodized to provide a decorative finish and enhance its durability. Overall, aluminum profiles offer a practical and aesthetically pleasing solution for balustrades in both residential and commercial settings.

- What is the difference between 6063-T5 and 6061-T6 aluminum profiles?

- T6 treatment of aluminum alloy is solid solution treatment and artificial aging treatment. Aluminum alloy with different components can be treated with T6 as the solution is treated by heat treatment. However, the specific technological parameters vary according to the composition, such as solid solution temperature and aging temperature. 6061 of the T6 process is: solid solution treatment temperature of 530 degrees, artificial aging to make T6, the state is plate 160 degrees, bar and 80 thickness above plate 175 degrees.

- Aluminum profiles have relatively poor electrical insulation properties. Aluminum is a good conductor of electricity, meaning it allows the flow of electric current. However, aluminum profiles can be anodized or coated with insulating materials to enhance their electrical insulation properties.

- Yes, aluminum profiles are suitable for electrical grounding applications. Aluminum is a highly conductive material that allows for efficient flow of electrical current, making it an ideal choice for grounding systems. Additionally, aluminum profiles offer excellent corrosion resistance, durability, and cost-effectiveness, making them a reliable option for electrical grounding applications.

- Yes, aluminum profiles can be used in the construction of curtain walls. In fact, aluminum is one of the most commonly used materials for curtain wall systems due to its numerous advantageous properties. Aluminum profiles are lightweight yet strong, making them ideal for creating large and structurally sound curtain walls. Additionally, aluminum is highly resistant to corrosion, ensuring the longevity and durability of the curtain wall. It is also a highly versatile material that can be easily shaped and fabricated to meet specific design requirements, allowing for the creation of unique and aesthetically pleasing curtain walls. Furthermore, aluminum profiles can easily accommodate various components and features such as glazing, insulation, and ventilation systems, making them a popular choice for modern curtain wall designs. The use of aluminum profiles also allows for efficient installation and maintenance processes, as they can be prefabricated offsite and quickly assembled on-site. Overall, the use of aluminum profiles in the construction of curtain walls offers numerous benefits in terms of strength, durability, versatility, and aesthetics, making it a preferred choice for many architects and builders in the construction industry.

- Yes, aluminum profiles can be used in the manufacturing of furniture. Aluminum is a versatile and lightweight material that offers several advantages for furniture production. It is highly durable, resistant to corrosion, and has a high strength-to-weight ratio. These properties make it suitable for various furniture applications, including chairs, tables, shelving units, and frames. Additionally, aluminum profiles can be easily customized, allowing for the creation of unique and modern designs. The use of aluminum in furniture manufacturing also contributes to sustainability, as it is a recyclable material. Overall, aluminum profiles provide designers and manufacturers with flexibility and durability, making them a popular choice in the furniture industry.

- To avoid galling or seizing in aluminum profiles, several steps can be taken: 1. Apply lubricant: Use a suitable lubricant on the contact surfaces of the profiles. This reduces friction and heat, preventing galling or seizing. Be sure to choose a lubricant specifically made for aluminum to avoid any negative reactions. 2. Utilize surface treatments: Implement anodizing or protective coatings on the profiles. These treatments create a barrier between the profiles, minimizing direct metal-to-metal contact and decreasing the likelihood of galling or seizing. 3. Ensure proper design and materials: Make sure the profiles and their mating components have sufficient clearance and a proper fit. Avoid tight tolerances that can cause excessive contact pressure, which increases the risk of galling. Additionally, select materials with compatible hardness and avoid using dissimilar metals that may lead to galvanic corrosion. 4. Keep things clean: Maintain cleanliness by regularly cleaning the profiles and their mating surfaces, removing any dirt, debris, or contaminants. Foreign particles can increase friction and contribute to galling or seizing. 5. Implement regular maintenance: Establish a preventive maintenance program that includes periodic inspection, cleaning, and lubrication of the profiles. This helps identify any issues early on and ensures smooth operation over time. By following these preventive measures, the risk of galling or seizing in aluminum profiles can be minimized, resulting in longer-lasting performance.

- What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- 5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3,