Aluminium Extrusion Profiles For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

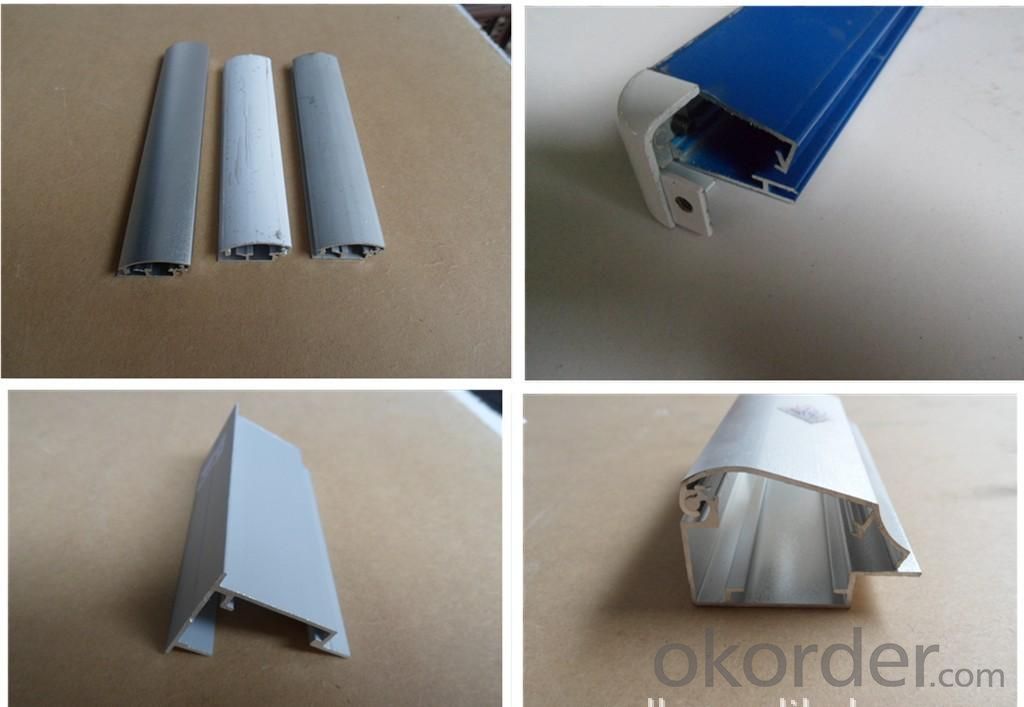

Product Name | Aluminium Extrusion Profiles For Construction |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q:how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q:Can aluminum profiles be used in solar panel installations?

- Yes, aluminum profiles can be used in solar panel installations. Aluminum is a popular choice for construction and engineering applications due to its lightweight, durability, and corrosion resistance. These characteristics make aluminum profiles an ideal material for solar panel installations. Aluminum profiles can be used to create sturdy and reliable frames for mounting solar panels. The lightweight nature of aluminum makes it easier to transport and install the panels, reducing the overall installation time and cost. Additionally, aluminum's corrosion resistance ensures that the frames will withstand exposure to various weather conditions over time, making them suitable for both residential and industrial solar panel installations. Moreover, aluminum profiles can be easily customized and fabricated to meet specific project requirements. They can be extruded into various shapes and sizes, allowing flexibility in designing the frames to fit different panel dimensions and orientations. Aluminum profiles can also be anodized or powder-coated to provide additional protection against environmental factors and enhance the aesthetic appeal of the installation. In summary, aluminum profiles are an excellent choice for solar panel installations. Their lightweight, durability, corrosion resistance, and customization options make them suitable for a wide range of applications and ensure the longevity and efficiency of the solar panel system.

- Q:Can aluminum profiles be used in modular construction systems?

- Modular construction systems readily employ aluminum profiles due to their lightweight and durable nature. These profiles, constructed from aluminum, are highly suitable for modular construction purposes. Not only do they confer structural stability, but they can also be easily manipulated into different shapes and sizes to meet specific design needs. Additionally, aluminum profiles exhibit exceptional resistance to corrosion, rendering them highly suitable for both indoor and outdoor applications. Furthermore, their recyclability makes them a sustainable choice for modular construction systems, aligning with environmentally-friendly practices. On the whole, aluminum profiles present a plethora of advantages in terms of strength, flexibility, and sustainability, thus solidifying their popularity within the world of modular construction.

- Q:Are aluminum profiles suitable for use in automotive engine components?

- Yes, aluminum profiles are suitable for use in automotive engine components. Aluminum is lightweight, which helps improve fuel efficiency and reduce emissions. It also has good heat conductivity, allowing for efficient heat dissipation in engine components. Additionally, aluminum profiles offer excellent strength and durability, making them suitable for withstanding the demanding conditions of an automotive engine.

- Q:What are the advantages of industrial aluminum profiles? What are the problems that should be paid attention to?

- Among a large number of aluminum processing materials, a large number of international advanced products and national famous brand products have emerged, representing the mainstream of the development and application of modern aluminum processing technology in china.

- Q:How many tons of aluminum can be produced by a ton of aluminium ingots?

- Firstly, according to the requirements of a ton of aluminum ingot made of different aluminum alloy rods, concrete can output many aluminum rods must be based on the company's standard, but personally think that a ton of aluminum rod is absolutely not up to a ton of waste in the section product, because in the process of consumption, waste can not be calculated in the product section in.

- Q:How are aluminum profiles insulated?

- Aluminum profiles can be insulated in several ways to enhance their thermal performance. One common method is to incorporate a thermal break within the profile design. This involves the insertion of a non-conductive material, such as polyamide or polyurethane, between the inner and outer parts of the profile. This thermal break helps to minimize heat transfer between the interior and exterior of a building, thus improving energy efficiency. Another approach to insulating aluminum profiles is through the application of insulating materials, such as foam or rubber, on the interior or exterior surfaces of the profile. These materials act as barriers to reduce heat transfer and provide additional insulation. Furthermore, aluminum profiles can also be fitted with insulating gaskets or seals. These gaskets are typically made of rubber or other insulating materials and are positioned between the profile and the glazing, creating a thermal barrier and preventing heat loss or gain. Overall, the insulation of aluminum profiles involves incorporating thermal breaks, applying insulating materials, or using gaskets to minimize heat transfer and improve the energy efficiency of buildings.

- Q:How to identify and distinguish the inferior aluminum profile and the poor aluminum profile four?

- First, extrusion defects.Aluminum extrusion process for machine equipment is perfect, process technology is mature and whether the operation staff misconduct and other reasons, will lead to aluminum flakes, such as inclusion, delamination, chromatic aberration, distortion and other defects, affecting the quality of aluminum profiles.Second, the film thickness is thin.Industrial aluminum oxide film thickness standard should be not less than 10um (m). If the thickness is not enough, the surface of the aluminum profile is easy to rust and corrode and shorten the service life. In order to save the cost, the thickness of the oxide film is only 2 to 4um, and some even have no oxide film. It is estimated that each reduction of 1um film thickness can reduce power consumption by more than 150 yuan per ton.

- Q:Can aluminum profiles be used in display stand and podium manufacturing?

- Yes, aluminum profiles can definitely be used in display stand and podium manufacturing. Aluminum is a highly versatile and durable material that offers several advantages such as lightweight, corrosion resistance, and easy customization. It can be easily shaped and fabricated into various designs and sizes, making it suitable for creating aesthetically appealing and functional display stands and podiums. Additionally, aluminum profiles can also be an excellent choice for portable or temporary setups due to their portability and easy assembly.

- Q:Are aluminum profiles suitable for use in aerospace structural components?

- Yes, aluminum profiles are suitable for use in aerospace structural components. Aluminum is a lightweight and strong material, making it an ideal choice for aerospace applications where weight reduction is crucial. It offers high strength-to-weight ratio, excellent corrosion resistance, and good formability, allowing for the fabrication of complex shapes and structures. Additionally, aluminum profiles can be easily joined using various techniques such as welding, riveting, or adhesive bonding, making them versatile for the assembly of aerospace structural components. Overall, the combination of its properties and ease of manufacturing make aluminum profiles a suitable choice for use in aerospace structural components.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Extrusion Profiles For Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords