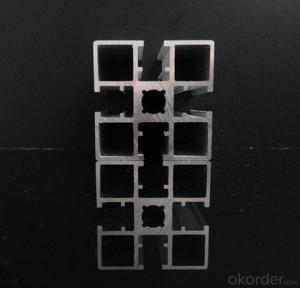

Alloy 7005 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description

Product Name | Alloy 7005 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q:Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. They are lightweight, durable, and easy to assemble and disassemble, making them ideal for creating versatile and portable booth structures. Additionally, aluminum profiles offer a sleek and modern aesthetic, allowing for customization and branding opportunities.

- Q:What are the different surface brushing options for aluminum profiles?

- The different surface brushing options for aluminum profiles include mechanical brushing, chemical brushing, and electrochemical brushing. Mechanical brushing involves the use of abrasive materials or brushes to create a brushed finish on the surface. Chemical brushing involves the application of chemicals or acids to etch the surface and create a brushed effect. Electrochemical brushing uses an electric current to create a brushed finish by removing material from the surface.

- Q:Can aluminum profiles be used for curtain walls?

- Yes, aluminum profiles can be used for curtain walls. Aluminum is a popular material choice for curtain wall systems due to its lightweight, durability, and corrosion resistance. It offers flexibility in design, ease of installation, and can accommodate large glass panels, making it an ideal choice for modern architectural designs.

- Q:What are the different types of aluminum alloys used for profiles?

- Profiles are commonly made using various types of aluminum alloys. Some of the most frequently used alloys include: 1. 6061 Aluminum Alloy: This versatile alloy is widely utilized due to its excellent combination of strength, weldability, and resistance to corrosion. It finds extensive use in structural applications, as well as for producing frames, railings, and automotive parts. 2. 6063 Aluminum Alloy: Known for its exceptional formability and ability to be extruded, this alloy is ideal for creating profiles. It offers good corrosion resistance and can be easily shaped into intricate designs. It is commonly employed in architectural applications like window frames, door frames, and curtain walls. 3. 7075 Aluminum Alloy: Renowned for its high strength-to-weight ratio and remarkable fatigue strength, this alloy is frequently used in aerospace applications. It is also favored for manufacturing high-performance products such as bicycle frames and sporting goods. 4. 5083 Aluminum Alloy: Particularly suitable for marine applications, this alloy demonstrates excellent corrosion resistance in saltwater environments. It is commonly utilized in the construction of boat hulls, decks, and other marine structures. 5. 3003 Aluminum Alloy: This alloy is known for its favorable formability, corrosion resistance, and weldability. It is widely employed in general-purpose applications, including signage, electrical enclosures, and kitchenware. These examples provide a glimpse into the diverse range of aluminum alloys used for profiles. The choice of alloy depends on specific requirements like strength, corrosion resistance, formability, and cost.

- Q:What kind of self tapping screw can attack aluminum profile?

- General aluminum, iron, stainless steel can attack ah!

- Q:Can aluminum profiles be used for solar power systems?

- Indeed, solar power systems can utilize aluminum profiles. The utilization of aluminum is widespread in the fabrication of solar panels and their supporting frameworks. Its lightweight characteristic, remarkable strength-to-weight ratio, and superior resistance to corrosion make it a favored material. Frequently employed for the framing and installation of solar panels, aluminum profiles offer both structural stability and enduring qualities. Notably, aluminum is effortlessly recyclable, rendering it an environmentally-conscious option for solar power systems.

- Q:Can aluminum profiles be used for access control systems?

- Yes, aluminum profiles can be used for access control systems. Aluminum profiles are commonly used in the construction of access control systems due to their durability, lightweight nature, and corrosion resistance. They provide a sturdy framework for mounting access control devices such as card readers, keypads, and biometric scanners. Additionally, aluminum profiles offer flexibility in design and can be easily customized to fit specific requirements of access control systems.

- Q:Can aluminum profiles be used for modular shelving systems?

- Yes, aluminum profiles can be used for modular shelving systems.

- Q:What are the advantages of using aluminum profiles in the telecommunications industry?

- Aluminum profiles offer numerous benefits for the telecommunications industry. Firstly, they possess a combination of lightweight and robust qualities, making them ideal for constructing infrastructure like antenna towers and satellite dishes. Their lightweight nature facilitates easy transportation and installation, resulting in time and cost savings. Secondly, aluminum profiles boast exceptional resistance to corrosion. This property is of utmost importance in the telecommunications industry, where exposure to harsh weather conditions and corrosive elements such as saltwater is common. Aluminum profiles can withstand these conditions without deterioration, guaranteeing the longevity and reliability of telecommunication equipment. Moreover, aluminum profiles are highly adaptable and can be easily tailored to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for the creation of intricate structures capable of accommodating different telecommunications equipment. This versatility streamlines the integration of various components and simplifies the installation and maintenance processes. Additionally, aluminum profiles possess excellent thermal conductivity, a crucial characteristic in the telecommunications industry. As telecommunication equipment generates heat during operation, effective heat dissipation is essential to prevent overheating and equipment failure. Aluminum profiles efficiently dissipate heat, ensuring optimal performance and prolonged lifespan of telecommunication devices. Finally, aluminum is a sustainable and environmentally friendly material. It is entirely recyclable, meaning that old or damaged aluminum profiles can be recycled and transformed into new products, thereby minimizing waste and reducing the environmental footprint. By incorporating aluminum profiles into their operations, the telecommunications industry can contribute to sustainability efforts. In summary, the advantages of utilizing aluminum profiles in the telecommunications industry encompass their lightweight yet sturdy nature, corrosion resistance, adaptability, thermal conductivity, and sustainability. These characteristics make aluminum profiles an excellent choice for constructing telecommunication infrastructure, ensuring reliable performance, and minimizing environmental impact.

- Q:Can aluminum profiles be used for stage and event structures?

- Stage and event structures can indeed make use of aluminum profiles. Aluminum, being both lightweight and durable, is a widely utilized material in the construction industry for a range of purposes, including stage and event structures. Aluminum profiles possess versatility, allowing for easy shaping, cutting, and joining to create customized structures. With an excellent strength-to-weight ratio, they are well-suited for supporting heavy equipment and ensuring the safety of performers and audience members. Moreover, aluminum profiles can be powder-coated or anodized, providing both a decorative finish and protection against corrosion. This enhances the visual appeal and longevity of the structures. In conclusion, aluminum profiles are a popular option for stage and event structures due to their versatility, strength, and aesthetic qualities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy 7005 Aluminium Extrusion Profiles For Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords