All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you calculate the return on investment (ROI) for projects involving aluminum profiles in various industries and applications?

To calculate the return on investment (ROI) for projects involving aluminum profiles in various industries and applications, you need to consider the initial investment, which includes the cost of acquiring and installing the profiles, as well as any additional expenses such as maintenance and operation costs.

Next, you need to estimate the financial benefits generated by the project, which could include factors like increased efficiency, reduced energy consumption, improved product quality, or cost savings. These benefits can be quantified in monetary terms.

Once you have determined the initial investment and estimated financial benefits, you can calculate the ROI using the formula: ROI = (Net Profit / Initial Investment) x 100. Net profit is calculated by subtracting the initial investment from the total financial benefits.

It's important to note that the accuracy of the ROI calculation depends on the accuracy of the estimates made for both the initial investment and the financial benefits. Additionally, ROI should be considered alongside other factors like payback period and risk analysis to make informed decisions about investing in projects involving aluminum profiles.

How do you calculate the deflection and stress in aluminum profiles under varying loads?

To calculate the deflection and stress in aluminum profiles under varying loads, several steps need to be followed. Firstly, the load distribution and boundary conditions must be determined. This includes identifying the points where the load is applied and any supports or restraints present.

Next, the beam theory equations, such as Euler-Bernoulli beam theory or Timoshenko beam theory, can be utilized to calculate the deflection and stress. These equations consider factors such as the moment of inertia, Young's modulus, and length of the aluminum profile.

Once the equations are set up, the load values and dimensions of the aluminum profile are inputted to obtain the deflection and stress values. These calculations can be performed manually or using software programs specifically designed for structural analysis.

It is important to note that aluminum profiles typically have specific design guidelines provided by manufacturers or industry standards. These guidelines may include additional factors to consider, such as safety factors, material properties, and specific load cases.

Overall, the calculation of deflection and stress in aluminum profiles under varying loads involves understanding the load distribution, applying appropriate beam theory equations, and considering any additional design guidelines to ensure accurate and safe results.

How do aluminum profiles perform in terms of energy efficiency in buildings?

Aluminum profiles have excellent thermal conductivity properties, allowing for effective heat transfer between indoor and outdoor environments. However, without proper thermal breaks or insulation, aluminum profiles can contribute to energy loss through thermal bridges. Therefore, to optimize energy efficiency in buildings, it is crucial to combine aluminum profiles with appropriate insulation and design strategies to minimize heat transfer and enhance overall thermal performance.

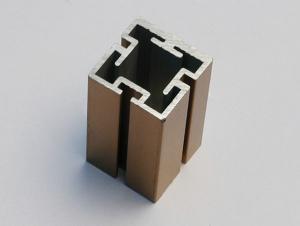

Wholesale Aluminum Profiles from supplier in Portugal

Whether you are in the construction, automotive, or manufacturing industry, our Aluminum Profiles are designed to meet your specific requirements. We offer a wide range of profiles, including standard and customized options, to ensure that you can find the perfect fit for your project.

Our team of experts is dedicated to providing excellent customer service and support throughout the entire process. From assisting with product selection and providing detailed quotations to offering technical advice and guidance, we are here to help you make informed decisions.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and high-quality products.

No matter the size or complexity of your project, we are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your Aluminum Profiles requirements and let us provide you with a tailored solution that fits your needs.

Our team of experts is dedicated to providing excellent customer service and support throughout the entire process. From assisting with product selection and providing detailed quotations to offering technical advice and guidance, we are here to help you make informed decisions.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing, reliable delivery, and high-quality products.

No matter the size or complexity of your project, we are committed to meeting your needs and exceeding your expectations. Contact us today to discuss your Aluminum Profiles requirements and let us provide you with a tailored solution that fits your needs.