All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

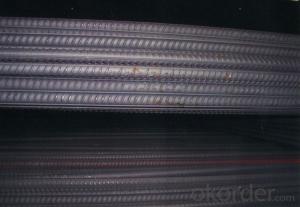

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of anchorage length in ensuring the proper attachment of steel rebars in concrete?

The role of anchorage length is crucial in ensuring the proper attachment of steel rebars in concrete. Anchorage length refers to the length of the rebar that is embedded in the concrete, providing a strong bond between the two materials. This bond is essential for transferring forces between the concrete and the steel reinforcement, thereby enhancing the structural integrity and load-bearing capacity of the reinforced concrete element. Insufficient anchorage length can result in inadequate bond strength, leading to potential failure or reduced performance of the reinforced concrete structure. Therefore, ensuring an appropriate anchorage length is vital for the effective and reliable performance of steel rebars in concrete.

What is the difference between straight and bent steel rebars?

The main difference between straight and bent steel rebars is their shape and intended use. Straight steel rebars are typically used in construction projects where reinforcement is needed in a straight line, such as in beams and columns. On the other hand, bent steel rebars are shaped to fit specific requirements, often used in structures that have curved or angled sections, such as in curved walls or slabs. The bending process enables the rebars to provide reinforcement in complex shapes and angles, optimizing structural strength and stability.

How do you evaluate the quality and reliability of couplers for steel rebar splicing?

To evaluate the quality and reliability of couplers for steel rebar splicing, several factors need to be considered. Firstly, it is important to assess the manufacturer's reputation and experience in producing couplers. Established and reputable manufacturers are more likely to produce high-quality and reliable couplers.

Secondly, examining the coupler's material and design is crucial. The coupler should be made from a durable and corrosion-resistant material, such as stainless steel, to ensure its longevity and performance. The design should be engineered to provide a secure and strong connection between the rebars.

Thirdly, conducting tests and certifications on the couplers is essential. Look for couplers that have been tested and certified by independent third-party organizations, such as ASTM or ICC, to meet industry standards for quality and reliability.

Additionally, seeking feedback from other professionals in the construction industry who have used the same couplers can provide valuable insights. Reviews and recommendations from trusted sources can help gauge the performance and reliability of the couplers.

By considering the manufacturer's reputation, material and design, certifications, and feedback from industry professionals, one can effectively evaluate the quality and reliability of couplers for steel rebar splicing.

What are the safety considerations when working with steel rebars?

When working with steel rebars, there are several important safety considerations to keep in mind. First and foremost, it is crucial to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect against potential injuries. Additionally, workers should be cautious of the sharp edges and protrusions of rebars, as they can cause cuts or puncture wounds. It is essential to handle and transport rebars properly, using lifting equipment or techniques to avoid back strains or other musculoskeletal injuries. Moreover, workers should be aware of the potential hazards associated with working at heights or in confined spaces when installing or positioning rebars. Following proper safety protocols, including regular inspections of equipment and work areas, can help mitigate these risks and ensure a secure work environment.

Wholesale Steel Rebars from supplier in Portugal

With our expertise and industry knowledge, we can help you find the right Steel Rebars products for your specific needs and requirements. Whether you are working on a construction project, infrastructure development, or any other steel reinforcement application, we can assist you in finding the best solutions.

Our team of professionals is dedicated to providing exceptional customer service and ensuring your satisfaction. From the initial sales inquiry to the final delivery of the Steel Rebars, we will be there to support you every step of the way. Our sales representatives are knowledgeable about our product range and can provide you with accurate and competitive quotations.

In addition, we offer technical support to help you make informed decisions about the Steel Rebars products that will best suit your project. Our technical experts can assist with product specifications, installation guidelines, and any other technical queries you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and a strong supply chain. This enables us to offer you competitive prices and timely delivery of your Steel Rebars products.

We understand the importance of quality and reliability in the construction industry. That is why we only work with reputable manufacturers and suppliers to ensure that our Steel Rebars products meet the highest standards.

Partnering with us means you can rely on a trusted and experienced supplier for all your Steel Rebars needs in Portugal. Contact us today to discuss your requirements and let us help you find the perfect solution for your project.

Our team of professionals is dedicated to providing exceptional customer service and ensuring your satisfaction. From the initial sales inquiry to the final delivery of the Steel Rebars, we will be there to support you every step of the way. Our sales representatives are knowledgeable about our product range and can provide you with accurate and competitive quotations.

In addition, we offer technical support to help you make informed decisions about the Steel Rebars products that will best suit your project. Our technical experts can assist with product specifications, installation guidelines, and any other technical queries you may have.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and a strong supply chain. This enables us to offer you competitive prices and timely delivery of your Steel Rebars products.

We understand the importance of quality and reliability in the construction industry. That is why we only work with reputable manufacturers and suppliers to ensure that our Steel Rebars products meet the highest standards.

Partnering with us means you can rely on a trusted and experienced supplier for all your Steel Rebars needs in Portugal. Contact us today to discuss your requirements and let us help you find the perfect solution for your project.