All Categories

- - Steel Wire Rod

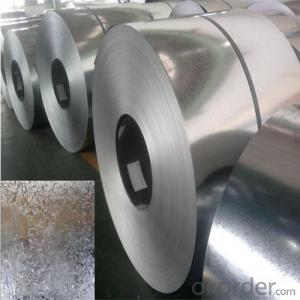

- - Steel Coils

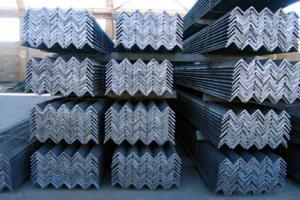

- - Steel Profiles

- - Steel Pipes

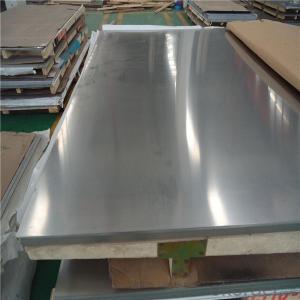

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the unique challenges and requirements for using cold-rolled steel in extreme temperature environments?

Cold-rolled steel in extreme temperature environments faces several unique challenges and requirements. Firstly, cold-rolled steel tends to become more brittle at low temperatures, making it susceptible to cracking and failure. To address this, careful consideration must be given to the selection of the proper alloy and the steel's microstructure. Additionally, thermal expansion and contraction can cause dimensional changes and stress on the steel, leading to potential distortions and structural issues. To mitigate this, proper design and fabrication techniques, including allowance for thermal expansion, are necessary. Furthermore, extreme temperatures can accelerate corrosion and oxidation, necessitating the use of protective coatings or alloy additions to enhance the steel's resistance to these environmental factors. Overall, the selection, design, and protection of cold-rolled steel in extreme temperature environments require careful attention to prevent mechanical failures and maintain structural integrity.

How does cold-rolled steel perform in high-stress and load-bearing applications?

Cold-rolled steel performs exceptionally well in high-stress and load-bearing applications due to its superior strength, durability, and structural integrity. The cold-rolling process enhances the steel's hardness and toughness, allowing it to withstand heavy loads and extreme pressures without deforming or breaking. Its consistent thickness and smooth surface finish further enhance its performance and make it an ideal choice for applications such as construction, automotive manufacturing, and industrial machinery.

What are the considerations for using cold-rolled steel in the aerospace industry, including engine components?

There are several important considerations for using cold-rolled steel in the aerospace industry, particularly for engine components. Firstly, cold-rolled steel offers enhanced strength and durability compared to regular steel, making it suitable for the demanding conditions experienced by aircraft engines. This strength allows the components to withstand high temperatures, vibrations, and stress during operation.

Another crucial factor is the dimensional accuracy and consistency provided by cold-rolling processes. Engine components require precise measurements and tight tolerances to ensure optimal performance and efficiency. Cold-rolling helps achieve these specifications, ensuring the components fit together seamlessly and function properly within the engine system.

Furthermore, cold-rolled steel exhibits excellent fatigue resistance, which is vital for engine components that are subjected to repetitive loading cycles. This property helps prevent the development of cracks or fractures over time, ensuring the longevity and reliability of the parts.

Additionally, the surface finish of cold-rolled steel is typically smoother and more uniform compared to other manufacturing methods. This smooth surface reduces friction and improves aerodynamic efficiency, contributing to enhanced engine performance and fuel efficiency.

Lastly, cold-rolled steel offers good formability, allowing it to be shaped into intricate and complex designs required for aerospace engine components. This versatility in manufacturing enables the production of customized parts that meet specific performance requirements.

Overall, the considerations for using cold-rolled steel in the aerospace industry, including engine components, revolve around its enhanced strength, dimensional accuracy, fatigue resistance, smooth surface finish, and formability. These characteristics make cold-rolled steel a reliable and efficient choice for meeting the demanding needs of the aerospace industry.

What is the role of cold-rolled steel in the aerospace industry?

The role of cold-rolled steel in the aerospace industry is crucial as it is used to manufacture various components and structures that require high strength, durability, and resistance to extreme conditions. Cold-rolled steel is commonly used in the construction of aircraft frames, wings, landing gear, and engine components. Its superior mechanical properties, such as improved tensile strength and hardness, allow for lightweight designs while maintaining structural integrity and safety. Additionally, the precise dimensional tolerances achieved through cold rolling ensure consistent and accurate fabrication of aerospace parts, contributing to the overall performance and efficiency of aircraft.

Wholesale Cold Rolled Steel from supplier in Portugal

Additionally, we pride ourselves on our commitment to sustainability and environmental responsibility. We strive to minimize our carbon footprint by implementing eco-friendly practices throughout our operations. Our Cold Rolled Steel products are manufactured using sustainable processes and materials, ensuring that your projects align with the principles of environmental stewardship.

Furthermore, we understand the importance of timely and efficient delivery. Our logistics team is well-equipped to handle the transportation and delivery of Cold Rolled Steel products to your desired location in Portugal. We work closely with trusted shipping partners to ensure that your orders are delivered on time and in excellent condition.

In terms of technical support, our team of experts is readily available to answer any questions or provide guidance on Cold Rolled Steel specifications, applications, and installation. We have in-depth knowledge of industry standards and regulations, ensuring that our products meet the highest quality and safety standards.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by providing exceptional service, competitive pricing, and superior Cold Rolled Steel products. Partner with us and experience the difference of working with a reputable supplier that is dedicated to meeting your Cold Rolled Steel needs in Portugal. Contact us today to discuss your requirements and let us provide you with a comprehensive solution.

Furthermore, we understand the importance of timely and efficient delivery. Our logistics team is well-equipped to handle the transportation and delivery of Cold Rolled Steel products to your desired location in Portugal. We work closely with trusted shipping partners to ensure that your orders are delivered on time and in excellent condition.

In terms of technical support, our team of experts is readily available to answer any questions or provide guidance on Cold Rolled Steel specifications, applications, and installation. We have in-depth knowledge of industry standards and regulations, ensuring that our products meet the highest quality and safety standards.

At our company, customer satisfaction is our top priority. We strive to exceed your expectations by providing exceptional service, competitive pricing, and superior Cold Rolled Steel products. Partner with us and experience the difference of working with a reputable supplier that is dedicated to meeting your Cold Rolled Steel needs in Portugal. Contact us today to discuss your requirements and let us provide you with a comprehensive solution.