All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

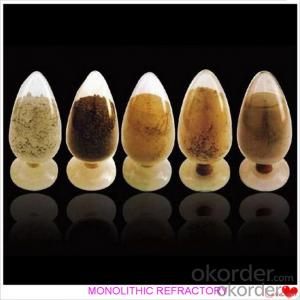

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

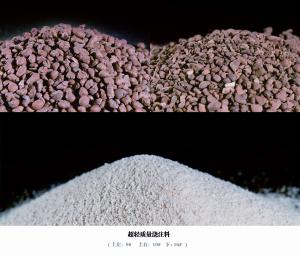

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining lead casting furnaces?

Yes, monolithic refractories can be used for lining lead casting furnaces. Monolithic refractories, which are a type of heat-resistant material, are suitable for various high-temperature applications including lead casting furnaces. They provide effective insulation, thermal shock resistance, and resistance to chemical erosion, making them a suitable choice for lining lead casting furnaces.

What are the key factors influencing the chemical composition of monolithic refractories?

The key factors influencing the chemical composition of monolithic refractories include the type and quality of raw materials used, the presence of additives or binders, the manufacturing process, and any desired performance characteristics or specific applications requirements.

Are monolithic refractories suitable for use in kilns?

Yes, monolithic refractories are suitable for use in kilns. They offer excellent thermal insulation, high temperature resistance, and can be easily shaped and installed to match the specific requirements of the kiln. Monolithic refractories also provide good resistance to chemical attacks and mechanical stresses, making them a reliable choice for kiln linings.

What are the limitations of monolithic refractories?

Monolithic refractories, while versatile and widely used, have certain limitations. One limitation is their susceptibility to thermal shock, especially when exposed to rapid temperature changes. This can lead to cracking and failure of the refractory material. Additionally, monolithic refractories may have lower mechanical strength compared to other types of refractories, making them more prone to wear and erosion. Their installation can be more complex and time-consuming, requiring skilled labor and specialized equipment. Moreover, monolithic refractories may have limited resistance to certain chemicals or corroding agents, reducing their suitability for specific industrial applications.

What are the main factors affecting the drying and curing of monolithic refractories?

The main factors affecting the drying and curing of monolithic refractories include temperature, humidity, and time. These factors play a crucial role in the removal of water from the refractory material and the development of its desired properties. Proper control of temperature and humidity during the drying and curing process is essential to prevent cracking, shrinkage, and other defects, ensuring the refractories achieve optimal strength and performance. Additionally, the duration of the drying and curing process is important to allow sufficient time for the chemical reactions and structural transformations to occur, resulting in a durable and stable monolithic refractory.

Wholesale Monolithic Refractories from supplier in Portugal

Our team of experts understands the unique challenges and requirements of the Portuguese market, and we work closely with our clients to develop customized solutions that meet their specific needs. Whether you need Monolithic Refractories for steel, cement, glass, or other industries, we have the expertise and resources to deliver top-quality products that will optimize your operations and increase productivity.

In addition to supplying Monolithic Refractories, we also provide expert consultation and technical support services. Our team of experienced professionals can assist you in selecting the right products for your specific applications, as well as provide guidance on installation and maintenance. We understand the importance of reliable and efficient refractory materials in your operations, and we are committed to ensuring that you have the support you need to keep your operations running smoothly.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing and a seamless procurement process for our clients in Portugal. We understand the importance of timely delivery and efficient logistics, and we work closely with our partners to ensure that your orders are delivered on time and in the most cost-effective manner.

At our company, we pride ourselves on our commitment to customer satisfaction. We strive to build long-term relationships with our clients, and we go above and beyond to ensure that their needs are met. Our team is dedicated to providing excellent customer service and support, and we are always available to answer any questions or address any concerns that our clients may have.

If you are in need of Monolithic Refractories solutions in Portugal, we encourage you to contact us. Our team of experts is ready to assist you and provide you with the high-quality products and services that you need to succeed. We look forward to partnering with you and contributing to the success of your projects.

In addition to supplying Monolithic Refractories, we also provide expert consultation and technical support services. Our team of experienced professionals can assist you in selecting the right products for your specific applications, as well as provide guidance on installation and maintenance. We understand the importance of reliable and efficient refractory materials in your operations, and we are committed to ensuring that you have the support you need to keep your operations running smoothly.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and expertise. This allows us to offer competitive pricing and a seamless procurement process for our clients in Portugal. We understand the importance of timely delivery and efficient logistics, and we work closely with our partners to ensure that your orders are delivered on time and in the most cost-effective manner.

At our company, we pride ourselves on our commitment to customer satisfaction. We strive to build long-term relationships with our clients, and we go above and beyond to ensure that their needs are met. Our team is dedicated to providing excellent customer service and support, and we are always available to answer any questions or address any concerns that our clients may have.

If you are in need of Monolithic Refractories solutions in Portugal, we encourage you to contact us. Our team of experts is ready to assist you and provide you with the high-quality products and services that you need to succeed. We look forward to partnering with you and contributing to the success of your projects.

Hot Search

- Monolithic Refractories in Uganda

- Ceramic Fiber Products in Lithuania

- Refractory Bricks in Azerbaijan

- Raw Materials For Refractory in Albania

- Refractory Bricks in Egypt

- Ceramic Fiber Products in Belarus

- Refractory Bricks in Monaco

- Raw Materials For Refractory in Haiti

- Ceramic Fiber Products in Ethiopia

- Ceramic Fiber Products in Croatia