Aluminium Extrusion For Honda Spareparts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Extrusion For Honda Spareparts Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Extrusion For Honda Spareparts:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

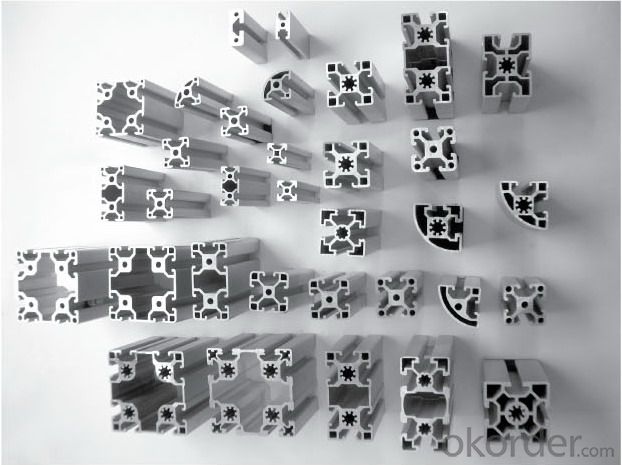

Images of the Aluminium Extrusion For Honda Spareparts:

Aluminium Coins for Deep Drawing to Tube Comestic Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:What are the weight limitations of aluminum profiles?

- The weight limitations of aluminum profiles depend on various factors such as the dimensions, shape, and structural integrity of the profile itself. Aluminum profiles are generally lightweight and have a high strength-to-weight ratio, making them suitable for a wide range of applications. However, the maximum weight capacity will vary depending on the specific profile design and the intended use. Aluminum profiles can typically support a significant amount of weight, especially when they are properly engineered and reinforced. For simple structural applications, such as framing or support systems, aluminum profiles can handle loads ranging from a few hundred pounds to several thousand pounds. These profiles are commonly used in industries like construction, automotive, aerospace, and manufacturing. It is important to note that the load-bearing capacity of aluminum profiles can be enhanced through various techniques, such as increasing the thickness or adding reinforcing elements like gussets or braces. These modifications help to distribute the weight and improve the overall strength of the profile. Additionally, it is crucial to consider other factors such as the length of the profile, the type of connection or fastening method used, and the overall stability of the structure. These factors can affect the weight limitations and overall structural integrity of the aluminum profiles. To determine the specific weight limitations of aluminum profiles for a particular application, it is recommended to consult with a structural engineer or refer to the technical specifications provided by the manufacturer.

- Q:Can someone give me a direction? Thank you

- First of all, the country's biggest industrial enterprise profile Liaoning Zhongwang Liaoyuan Midas Shandong Shandong Hunan Guangxi South Nanshan jungle Sheng Tong Guangdong Luxe Guangdong and the United States they have or will soon be launched high-speed EMU industrial aluminum productsSecondly, the radiator done the best Guangxi south south aluminum, but the radiator specification too, radiator section do few enterprises, the majority of enterprises in the decentralized radiator, small cross section, you have to search.The best solar energy company is Jiangsu's Hyde aluminum, energy aluminum enterprises concentrated in Jiangsu and Zhejiang, it is recommended search.Mechanical equipment is divided into manufacturing machinery and medical equipment manufacturing machinery, aluminum is not much, much maintenance need new materials will purchase, medical devices are mostly aluminum fittings and seamless pipe, little section, which can satisfy the production enterprises can do.Transport can be divided into passenger cars and commercial vehicles in two categories, now on the domestic market of aluminum on the vehicle in popularity is also very slow, promotion is difficult, this is not a salesman to project, to promote the use of a wide range of industry to the understanding, or executive strategy, and promote the country policy......The one or two sentence that is not clear, industry market is still relatively confused, capacity is already saturated, according to the perspective of industrial development, 120% saturated, is conducive to healthy competition, eliminating inferior enterprises, promote the development of technology, but has been more than 150% saturated capacity in China, most are small extrusion machine for the production of building, 70% how to develop materials, industry, still have to see your company's positioning and strategic development.

- Q:Are aluminum profiles suitable for food processing applications?

- Aluminum profiles prove to be a fitting option for food processing applications. Aluminum, being a lightweight and corrosion-resistant material, finds extensive use in the food processing industry due to its numerous advantages. To begin with, aluminum profiles possess easy-to-clean and maintain properties, which are crucial in food processing environments where hygiene holds utmost importance. They can be effortlessly washed and sterilized, preventing any potential cross-contamination or bacterial growth. Moreover, aluminum is non-toxic and does not react with food or beverages, ensuring that the processed products' integrity and quality remain uncompromised. This aspect gains particular significance when dealing with acidic or alkaline foods that may react with other materials. Additionally, aluminum profiles exhibit exceptional thermal conductivity, facilitating efficient heat transfer during processing operations like baking or cooling. This feature guarantees uniform heat distribution, resulting in consistent outcomes. Furthermore, aluminum stands as a sustainable material that can be recycled repeatedly without losing its properties. This aspect aligns with the growing emphasis on sustainability and environmental responsibility in the food processing industry. In conclusion, the attributes of aluminum profiles render them a suitable choice for food processing applications, offering durability, cleanliness, and compatibility with food products.

- Q:Can aluminum profiles be used in the production of packaging materials?

- Aluminum profiles have the capability to be utilized for the creation of packaging materials. Renowned for its durability, lightweight nature, and strength, aluminum is an excellent selection for packaging applications. These profiles can be extruded into diverse shapes and sizes, accommodating personalized packaging solutions. They can be employed to fabricate packaging containers, like cans, bottles, and tubes, which are commonly utilized for food, beverages, pharmaceuticals, cosmetics, and various other consumer goods. The utilization of aluminum profiles in packaging materials presents numerous benefits, such as resistance to corrosion, impermeability to light, oxygen, and moisture, as well as ease of molding and printing. Furthermore, aluminum is a fully recyclable material, rendering it an environmentally conscious choice for packaging production. Ultimately, aluminum profiles serve as a dependable and effective alternative for the manufacturing of packaging materials.

- Q:Are aluminum profiles resistant to pests or insects?

- Generally, pests or insects are not a problem for aluminum profiles. This is because aluminum is a non-porous material that does not offer a suitable environment for pests or insects to nest or feed on. Unlike wood, which can be prone to termite infestations, aluminum profiles are not susceptible to insect damage. The smooth surface of aluminum makes it difficult for insects to crawl or burrow into, effectively preventing them from entering the structure. Moreover, aluminum profiles are frequently used for windows, doors, and other entry points, and their tight seals further restrict the entry of pests or insects into a building. In summary, aluminum profiles offer a long-lasting and pest-resistant solution for various applications.

- Q:What are the limitations of using aluminum profiles?

- When using aluminum profiles in various applications, it is important to take into account several limitations. First and foremost, heavy-duty or high-stress applications may not be suitable for aluminum profiles. Despite being a lightweight material, aluminum may not possess the same level of strength and rigidity as metals like steel, making it unable to withstand heavy loads or extreme forces. In addition, aluminum profiles are vulnerable to corrosion. While aluminum does have natural corrosion resistance due to the formation of a protective oxide layer, certain environments, especially those with high levels of moisture or chemicals, can still cause deterioration over time, compromising the profiles' structural integrity. Furthermore, aluminum has a relatively low melting point, which makes it more susceptible to heat damage compared to other metals. In applications involving high temperatures, such as certain industrial processes, aluminum profiles may not be the most suitable choice. Moreover, aluminum profiles may have limited design flexibility compared to other materials. While aluminum can be extruded into various shapes and sizes, it may not offer the same level of customization as materials like steel. This can be a constraint when attempting to achieve complex or intricate designs. Lastly, cost can also be a limiting factor when considering aluminum profiles. While aluminum is a widely available and cost-effective material, it may not be the most economical choice for certain applications. In cases where higher strength or specialized properties are required, alternative materials may prove to be more cost-efficient. In conclusion, while aluminum profiles offer numerous advantages such as being lightweight, corrosion-resistant, and affordable, it is crucial to consider these limitations before selecting them for specific applications. Evaluating the load requirements, environmental conditions, design constraints, and budgetary considerations will help determine if aluminum profiles are the most suitable option.

- Q:Can aluminum profiles be used in the production of industrial robots?

- Yes, aluminum profiles can be used in the production of industrial robots. Aluminum is a lightweight and durable material that offers several advantages for constructing robotic systems. It has a high strength-to-weight ratio, making it suitable for building rigid and reliable robot structures. Aluminum profiles can be easily machined, allowing for precise and intricate designs to be created for various robot components such as frames, arms, and joints. Additionally, aluminum is corrosion-resistant, which is beneficial in industrial settings where robots may be exposed to harsh environments or chemicals. Overall, aluminum profiles provide a cost-effective and versatile solution for manufacturing industrial robots.

- Q:What is the difference between 6061-T6 and 6063-T6 in aluminum profile?

- Different alloy components determine their mechanical properties differently, and each of the 6061 indexes is much better than 6063

- Q:Can aluminum profiles be used in telecommunications infrastructure?

- Yes, aluminum profiles can be used in telecommunications infrastructure. Aluminum is a lightweight and versatile material that offers several advantages in telecommunications applications. It is corrosion-resistant, which makes it suitable for outdoor installations where it may be exposed to harsh weather conditions. Aluminum profiles are also easy to fabricate and can be customized to meet specific requirements, such as mounting brackets, cable trays, or equipment racks. In addition, aluminum profiles have excellent electrical conductivity, which is crucial in telecommunications infrastructure to ensure efficient signal transmission. They can be used for various purposes, including the construction of transmission towers, antenna supports, and base stations. Furthermore, aluminum is a sustainable material as it can be recycled repeatedly without losing its properties. This aligns with the growing focus on environmental sustainability in the telecommunications industry. Overall, aluminum profiles offer a cost-effective and reliable solution for telecommunications infrastructure, providing durability, flexibility, and excellent electrical conductivity.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Extrusion For Honda Spareparts

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords