Aluminum Profiles 6063-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

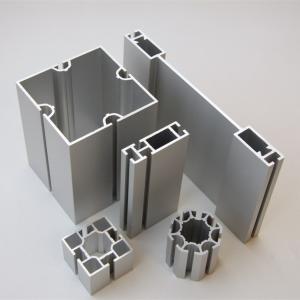

1 Specifications of Aluminum Profiles 6063-T5

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

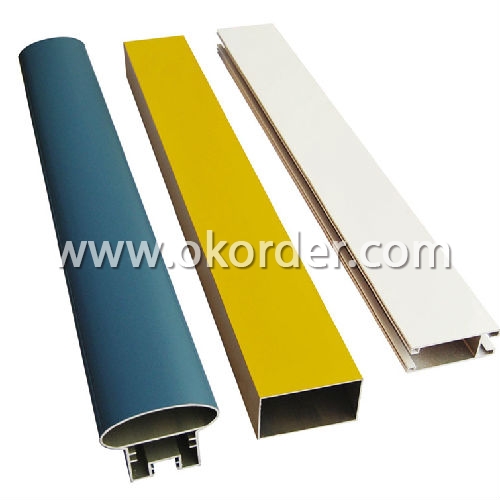

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6063-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

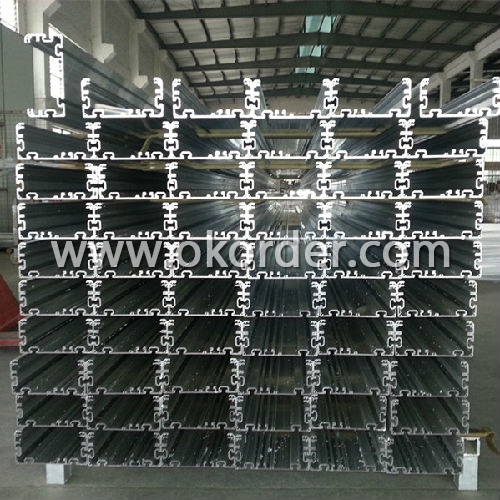

3 Packaging & Delivery of Aluminum Profiles 6063-T5

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles 6063-T5

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q:How do aluminum profiles contribute to sustainable building practices?

- Aluminum profiles contribute to sustainable building practices in several ways. Firstly, aluminum is a highly recyclable material, meaning that it can be reused and repurposed without losing its quality. This reduces the need for extracting and manufacturing new aluminum, reducing the overall environmental impact. Secondly, aluminum profiles are lightweight yet strong, allowing for efficient and cost-effective construction. This results in reduced energy consumption during transportation and installation. Additionally, aluminum is corrosion-resistant, ensuring durability and longevity of buildings, reducing the need for frequent replacements. Lastly, aluminum profiles can be designed to be thermally efficient, enhancing insulation and reducing energy consumption for heating and cooling. Overall, aluminum profiles promote sustainability by minimizing waste, conserving energy, and improving the lifespan of buildings.

- Q:Measuring 3 meters long aluminum profiles of the straightness, you have what good method? What is the maximum deviation value allowed by our industry? In addition to the platform measurement, and what are the economic and practical methods, our factory stalls are small. Consider input costs.

- For bending, twist test should be adopted according to the requirements of the platform, but in actual use, the platform used as a simple test tube can also be used to forming good Aluminum Alloy square or rectangular, note the tube before use, the first to confirm the test, can be used as a test platform.

- Q:Are aluminum profiles suitable for escalator handrails?

- Yes, aluminum profiles are suitable for escalator handrails. Aluminum is a lightweight and durable material that is commonly used in various applications, including escalator handrails. It offers excellent strength-to-weight ratio, corrosion resistance, and can withstand heavy loads and constant use. Additionally, aluminum profiles can be easily shaped and customized to meet the specific requirements of escalator handrails, providing a comfortable and ergonomic grip for users. Overall, aluminum profiles are a reliable and suitable choice for escalator handrails due to their strength, durability, and versatility.

- Q:You need is the extrusion machine section now has Liaoning Zhong Wang Liaoyuan Midas Nanshan aluminum aluminum Hunan Sheng Guangxi jungle SWA South northeast light alloy etc. they have more than 4500 tons of extrusion machine mainly produces large section comprises a track body profile LED lamp shell container ship with large cross section conductor rail section I is a seamless tube a market analyst if you have aluminum industrial material need to be aware of the problem you can consult me as friends.

- 4500T is not very large extrusion machine, a little aluminum factory are generally, in the hope of Liaoning, Qinghai Guoxin, Yun ore has more than 10000 tons of production lines, more than sixty percent domestic aluminum production is Guangdong Foshan, there are several manufacturers have the production line, such as Albert, Jianmei so, need to understand the aluminum things to find the best side to understand

- Q:What are the standard dimensions and sizes of aluminum profiles?

- The standard dimensions and sizes of aluminum profiles can vary depending on the specific application and industry. However, there are some common dimensions and sizes that are widely used in various industries. In general, aluminum profiles come in various shapes such as angles, channels, tubes, and bars. The dimensions of these profiles typically range from small to large, with sizes measured in terms of width, height, and thickness. For example, aluminum angle profiles commonly have dimensions ranging from 1/2 inch to 8 inches in width and height, with thicknesses ranging from 1/16 inch to 1/2 inch. Aluminum channel profiles can have widths ranging from 1/2 inch to 12 inches, heights ranging from 1/2 inch to 3 inches, and thicknesses ranging from 1/16 inch to 1/4 inch. Aluminum tube profiles often come in various outer diameters, ranging from 1/8 inch to 6 inches, with wall thicknesses ranging from 1/32 inch to 1/4 inch. Aluminum bar profiles typically have widths ranging from 1/8 inch to 12 inches, heights ranging from 1/8 inch to 4 inches, and thicknesses ranging from 1/16 inch to 1/2 inch. It is important to note that these dimensions and sizes are just a general guideline, and specific applications may require custom dimensions or sizes. Additionally, different countries or regions may have their own standards and variations in aluminum profile dimensions and sizes. Therefore, it is always advisable to consult with manufacturers or suppliers to determine the specific dimensions and sizes that meet your requirements.

- Q:I would like to know where Urumqi has industrial aluminum profiles, such as 3030, 4040, 3060 aluminum, etc., note that industrial aluminum, not doors and windows, aluminum profiles, the difference between the two very large!

- And shares in the east railway station there, the east railway station and then go one Station Road (near the North Main Road) can see.

- Q:Can aluminum profiles be used for curtain wall systems?

- Curtain wall systems can indeed utilize aluminum profiles. In fact, aluminum stands as one of the most prevalent materials employed in curtain wall construction due to its numerous advantages. The exceptional strength and durability of aluminum profiles allow them to bear the weight of large glass panels. Moreover, aluminum exhibits remarkable resistance to corrosion, a crucial characteristic for exterior applications where the curtain wall is exposed to various weather conditions. Additionally, aluminum profiles can be easily extruded into various shapes and sizes, offering design flexibility and customization. The lightweight nature of aluminum also facilitates easier handling and installation, resulting in reduced labor and transportation costs. Furthermore, aluminum is a sustainable material as it is recyclable, thereby contributing to the overall sustainability of the curtain wall system. In conclusion, the strength, durability, corrosion resistance, design flexibility, and sustainability of aluminum profiles make them an appropriate choice for curtain wall systems.

- Q:How do you join two aluminum profiles together?

- There are several ways to join two aluminum profiles together, depending on the desired strength, appearance, and functionality of the joint. Here are a few common methods: 1. Mechanical Fasteners: One of the simplest and most common methods is to use mechanical fasteners such as screws, bolts, or rivets. These fasteners can be drilled through both profiles and tightened to securely hold them together. It is important to choose the appropriate size and type of fastener based on the thickness and material of the profiles. 2. Welding: Welding is another popular method for joining aluminum profiles. It involves melting the aluminum at the joint and allowing it to solidify, creating a strong bond between the two profiles. There are different types of welding techniques that can be used, such as TIG (Tungsten Inert Gas) welding and MIG (Metal Inert Gas) welding, depending on the specific application and requirements. 3. Adhesives: Adhesive bonding is a non-invasive method for joining aluminum profiles. Specialized adhesives designed for bonding aluminum can be applied to the surfaces of the profiles and then pressed together. This type of joint is particularly useful when a seamless appearance is desired, as it eliminates the need for visible fasteners or welds. However, the strength of the adhesive bond may vary depending on the type of adhesive used. 4. Interlocking Systems: Some aluminum profiles are designed with interlocking systems that allow them to connect easily. These systems typically involve the use of connectors or accessories specifically designed for the profiles being used. They can provide a secure and sturdy joint while also simplifying the assembly process. When deciding how to join two aluminum profiles together, it is important to consider factors such as the strength requirements, aesthetics, ease of assembly, and disassembly if necessary. Additionally, it is recommended to consult with professionals or experts in aluminum fabrication to ensure the chosen method is appropriate for the specific application.

- Q:Are aluminum profiles suitable for use in pharmaceutical manufacturing?

- Yes, aluminum profiles are suitable for use in pharmaceutical manufacturing. Aluminum is a versatile and lightweight material that offers numerous advantages in the pharmaceutical industry. Firstly, aluminum profiles are corrosion-resistant, which is crucial in pharmaceutical manufacturing where cleanliness and hygiene are of utmost importance. Aluminum does not rust or deteriorate when exposed to moisture, making it ideal for use in cleanrooms and sterile environments. Secondly, aluminum profiles are easy to clean and maintain. They can withstand rigorous cleaning processes, including sterilization and disinfection, without losing their structural integrity. This ensures that the pharmaceutical manufacturing equipment remains in a pristine and contamination-free condition. Additionally, aluminum profiles can be customized to meet specific requirements in pharmaceutical manufacturing. They can be easily fabricated into various shapes and sizes, allowing for the creation of complex structures and machinery. This flexibility makes aluminum profiles an ideal choice for designing pharmaceutical equipment that requires precision, such as conveyor systems, processing machinery, and packaging equipment. Furthermore, aluminum profiles have excellent thermal conductivity. This property is advantageous in pharmaceutical manufacturing processes that involve temperature control, such as freeze-drying, sterilization, and granulation. The high thermal conductivity of aluminum allows for efficient heat transfer, ensuring that the pharmaceutical products are processed and stored at the desired temperature. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, reducing the carbon footprint associated with pharmaceutical manufacturing. Aluminum profiles can be reused and repurposed, contributing to a circular economy and minimizing waste generation. In conclusion, aluminum profiles are highly suitable for use in pharmaceutical manufacturing. Their corrosion resistance, ease of cleaning, customization options, thermal conductivity, and sustainability make them an excellent choice for designing and fabricating pharmaceutical equipment and machinery.

- Q:Are there any materials for aluminum profiles?

- Aluminum material can be classified as follows:By purpose1. architectural aluminum profiles (divided into two types of doors and windows and curtain wall)2. radiator aluminum profiles.3. general industrial aluminum: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, the electrical machinery industry and clean room with.4, rail vehicle structure aluminum alloy profile: mainly used for rail vehicle body manufacturing.5, Mount Aluminum profiles, made of aluminum alloy frame, mounted a variety of exhibitions and decorative paintings.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Profiles 6063-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons kg

- Supply Capability:

- 1000 Tons Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords