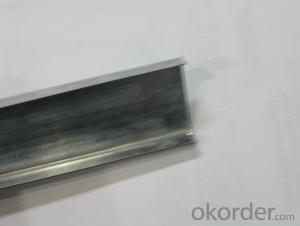

Stock Aluminum Profiles

Stock Aluminum Profiles Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Galvanized Steel Scrap Price Galvanized Steel Prices Stone Wall Tiles Cost Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For SaleStock Aluminum Profiles Supplier & Manufacturer from China

Okorder.com is a professional Stock Aluminum Profiles supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stock Aluminum Profiles firm in China.Hot Products

FAQ

- The wall thickness options for aluminum pipes can vary depending on the specific application and industry requirements. Generally, aluminum pipes are available in a range of wall thicknesses to accommodate different needs. The most common options for wall thicknesses in aluminum pipes include standard, schedule, and nominal sizes. Standard wall thicknesses are typically used in industrial applications where strength and durability are important. These pipes are manufactured with specific dimensions to meet industry standards and are often used in structural applications, such as construction or engineering projects. Schedule wall thicknesses, on the other hand, are primarily used in pressure applications, such as plumbing or fluid transfer systems. These pipes are designed to handle different levels of pressure and are identified by a schedule number, ranging from Schedule 5 to Schedule 160. Each schedule number corresponds to a specific wall thickness, with higher numbers indicating thicker walls capable of withstanding higher pressures. Nominal wall thicknesses refer to a range of wall thicknesses that fall within a certain tolerance level. These pipes are often used in general-purpose applications or where precise dimensions are not critical. The nominal size is a rounded value that corresponds to the approximate inside diameter of the pipe, while the wall thickness can vary within a certain range. It is important to note that the specific wall thickness options for aluminum pipes may vary depending on the manufacturer, industry standards, or custom requirements. Therefore, it is essential to consult the relevant specifications or consult with a supplier to determine the available options for a particular application.

- How to bend thin aluminum tube without flat

- Fill the sand with the aluminum tube and seal the ends with the pipe bender. If necessary, heat it up and drain the sand when it is bent.

- 6063, how to prevent cracking aluminum tube, variant manual bending machine bending machine bending, what should pay attention to?No one knows?

- 6063, aluminum tube plasticity is very good, if you want to bend, it is recommended to return the fire, reduce the hardness, bending after quenching, bend pipe bend can be.

- Yes, aluminum pipes are generally considered to be fire-resistant. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and does not burn easily. Additionally, aluminum forms a protective oxide layer on its surface when exposed to oxygen, which helps prevent further combustion. These characteristics make aluminum pipes a suitable choice for applications that require fire resistance, such as in industrial settings or for the transport of flammable substances. However, it is important to note that while aluminum pipes may be fire-resistant, they can still transfer heat and conduct electricity, so proper precautions and insulation should be taken when using them in potentially hazardous environments.

- The refrigerator can be used in soldering aluminum crack? Repair a Haier refrigerator, found that there is a little cracks in the aluminum tube in the freezer. Can solder wire be used to repair it?

- Certainly not for solder wire Lo, can move a little cushion water temperature is low, iron cloth flame is very short, prepare a fix, it is open and close back the money, can not move back out on the open

- How do you usually process hollow aluminum tubes? I want to make aluminum tubes myself

- What material to see? There are many kinds of aluminumAskI used it for unpowered delta wings. What type of aluminum is light, strong and cheap?. Domestic materialChasing the answerZL204

- The aluminum pipe joint on the unit is broken. Take a look at it. There is a copper ring on the aluminum tube. I don't know how it was pressed. Do you know any friend here? What equipment do you need to press up? Do you have any manual equipment? A friend who knows is better illustrated with a picture. Thank youThank you friends reply, but you're wrong, the copper ring is pressed up and see what this is the copper ring on both sides of the copper ring is a device pressure to take off the copper ring in the aluminum tube plays the role of sealing

- Screw it into a copper tube or an aluminum tube. That's what you do. There's an indentation at both ends,The new card can not be screwed up

- Yes, aluminum pipes can be used in HVAC systems. Aluminum is a lightweight and corrosion-resistant metal, making it an ideal choice for HVAC applications. Aluminum pipes are commonly used for air conditioning and refrigeration systems, as well as in heat exchangers and condensers. They offer excellent thermal conductivity, which allows for efficient heat transfer, and they are also durable and long-lasting. Additionally, aluminum pipes are easy to work with, as they can be easily cut, bent, and shaped to fit specific requirements. Overall, aluminum pipes are a reliable and cost-effective option for HVAC systems.