Galvanized Profiles for Dry Wall Galvanized Profiles for Dry Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

4.Easy and fast for installation,time-saving;

5.prompt delivery,high quality,competitive price and complete sets of style;

Main Product Features:

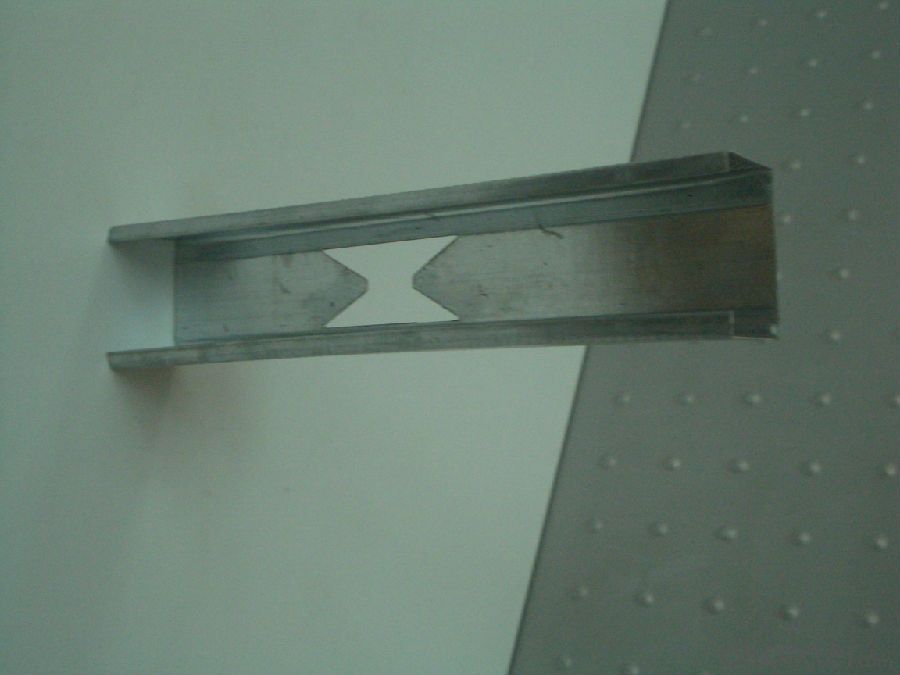

metal drywall system galvanized steel profile c channel

Our drywall studs are made of galvanized steel sheet with good rust-proof function. The thickness is strictly according to the international demand.

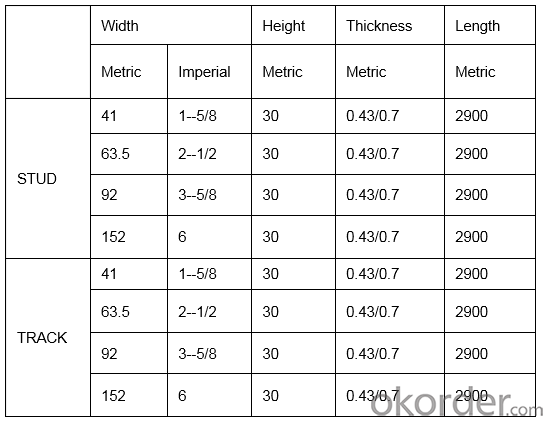

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q:Who used the light steel keel gypsum board to do the wall?

- Not compare province, province, then you buy bricks more province, just better installed than brick light

- Q:Light steel keel partition wall how to paint

- Light steel keel structure, to find the location of the keel, use a long self-tapping screws, forced into the screw. So that it can be stable.

- Q:With light steel keel gypsum board do partition wall price how to count?

- Baoqing about 25, all 100-130 (material pricing).

- Q:Light steel keel wall in the end is how much money to know

- Generally do light steel keel gypsum board wall package package material about 100 yuan a square meters. Mainly to see the price of materials, the general dragon licensing gypsum board and light steel keel more expensive.

- Q:100 square light steel keel wall how many pieces of heaven and earth keel

- Heaven and earth keel accurately depends on the length of the wall, the dragon than the dragon multi-hole size. Usually can be doubled the length of the wall to remove the door. Vertical spacing is usually 400, the door has to strengthen the vertical keel, wearing a keel to see the height of the wall, you can 1, but also two. Depending on the specific design. If the height of 3m, heaven and earth keel to 67m-several door size.

- Q:Lightproof wall how to fire

- And light steel keel installation door is the same light steel keel door frame after doing the light steel keel and then do a fixed two-layer woodworking board as a door cover and then the fire door fixed in the woodworking board or in the light steel keel fixed channel steel Made the door sets and then fixed fire doors or not the first gypsum board in the light steel keel on the back of the fixed fire door or with a channel or angle or simply use a wooden fire door

- Q:Light steel keel gypsum board partition wall brush black latex paint, I would like to change the brush blue latex paint, how to deal with grassroots?

- Can ah, the paper gypsum board above also scraping putty ah, the workers will deal with, you just ask the request on it, professional things professional do

- Q:Has installed a wooden floor, you can do in the above light steel keel wall?

- My advice is not to do on wooden flooring Because the wood floor is flexible. The The It is best to finish the wall, and then restore the floor Just personal opinion for reference only

- Q:How to do woodworking partition wall, with door

- Wood keel construction procedures: clean up the grass-roots level → line, looking for rules → in the ground with brick, cement mortar to do pillow belt (also known as kicker) → elastic line, back to the ceiling and the main structure of the wall → Vertical frame wall → installation along the ground, along the top of the flute → stand off the keel → nail cross keel → cover panel, set the socket location and set up to strengthen the pad wood panel cover.

- Q:How much does it cost to use a light steel keel gypsum board?

- 15 square meters of the wall 15 * 65 = 925 + ordinary door 300 - 400 + installation door hand fee 120 = 1345-1445. But the square is too small, the general companies do not want to do, the fare back and forth have much money.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Profiles for Dry Wall Galvanized Profiles for Dry Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords