Galvanized Profiles for Dry Wall Galvanized Profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Interior partition wall or veneering wall of hotels, theaters, emporiums, factories, office, house, airplane-terminal buildings, bus stations, waiting lounge, etc.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The partition of the bathroom and other wet condition building.

4.Indoor partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance;

2.Matching magnesium fire-proof board,gypsum board,and many other wall and ceiling board;

3.Moisture -proof,shock-resistance,high-effecient,environmentally-friendly and so on;

Main Product Features:

1)size:50*50*50/75*50*50/100*50*50mm

2)thickness:0.3-0.6mm

3)length:3000mm

4)accept customized size

5)shockproof, waterproof,fireproof

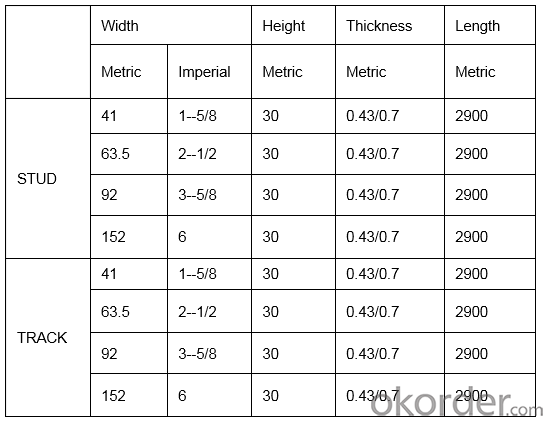

Product Specifications:

FAQ:

1:.How can I get your prompt quotation?

A: we can give you reply with quotation quickly if you kindly send the inquiry with specification.

2.What's the MOQ of the order?

No limit, we can offer the best suggestions and solutions according to your condition.

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don’t conform to customer’s samples or have quality problems, our company will be responsible to make compensation for it based on enough evidence.

Images:

- Q:Light steel keel gypsum board partition wall construction practices and construction process What is the difference?

- And traditional wooden keel wall for comparison? Basically, the framework is different, flatness is different, the cost is different.

- Q:What are the consequences of installing a hanging cabinet on gypsum board wall?

- Gypsum board can not load, do not install gypsum board door hanging cabinet. If the impact of drilling position is keel, then the impact of the impact of drilling, will issue a big voice, and the whole wall has a shock; if the keel is light steel keel, it will soon penetrate, But it is possible to make the fixed gypsum board screws off, causing the gypsum board loose; if it is wood keel, the impact drill can play wood slag to.

- Q:To warm the above has been tiled, with light steel keel to build a wall, how to fix the keel?

- With a hammer to drill the ground hole can be fixed to the ground. With glue, it is certainly impossible to nail

- Q:Is it possible to use a hollow brick or a 95 brick?

- With hollow bricks, because it is relatively light, will not cause the floor cracking. In fact, there are many other wall materials, including light steel keel gypsum board, steel mesh, etc., both light, but also save the space as usual when you decorate the brick wall should be used 1/2 brick wall, if the hollow brick Do, the wall width of the brush with 120 thick, the main advantage is the weight of light is generally 95 brick wall 2/3, will not bring too much burden on the structure of the house itself, noise effects can be, because the hollow brick inside Hole in the arrangements on the noise function to consider, relatively speaking, 95 brick wall thickness and hollow brick is the same, heavy weight, sound insulation effect than the hollow brick to slightly better. But I suggest that the main building brick wall, then the best use of steam concrete blocks, to achieve the best results!

- Q:Will the light steel keel, brick block, light partition wall do inside the wall what are the advantages. Including the price, as much as possible, thank you!

- Light steel keel life in humid environment Short brick block from the weight of large but because the single volume of small transport more convenient light partition board can be used for humid environment but a single volume upstairs is not convenient to install as light steel keel convenience The cost gap is not big

- Q:In Shanghai 75 partition wall light steel keel 0.6 what price now

- Low-grade 3.5-4.5 yuan / m range. Light steel keel, flower head a lot. Side high, the actual thickness, galvanized surface, strip material are very affected price.

- Q:Wood keel can be used to ceiling, can be used to do the wall? Light steel keel can be used in what place?

- Wood keel is best used, one is poor fire, the second is easy to produce pests, and now the ceiling are gradually replaced by light steel keel keel.

- Q:Curved gypsum board wall technology.

- Curved (sub-bumps) of the construction method: the first with the blockboard to make the first arc, in the right place with keel (wood keel, light steel keel can be) to shape the joinery board, and then gypsum board Attached to the blockboard and keel on the line. The following figure is the arc (concave) top of the grass-roots approach, curved wall practice with it the same.

- Q:How to install damping sound insulation felt

- Noise board installed C100 light steel keel, keel on the inside of the nail pad a layer of sound insulation felt, to avoid rigid connection, keel gap filled with weight 40,35 two-layer sound-absorbing cotton

- Q:Do the decoration of the brethren, I would like to ask: inside the plant to do light steel keel ceiling, partition (are ordinary), package the price of how much?

- 50-type light steel keel ceiling to pay keel by 400 open dragon licensing gypsum board 30 yuan per square is not labor costs. The final price or depends on what you choose what kind of top child, and if there is a complex shape that according to the design drawings Offer it. Search the general ceiling in about 200 or so. Hope to help you, hope to adopt.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Galvanized Profiles for Dry Wall Galvanized Profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords