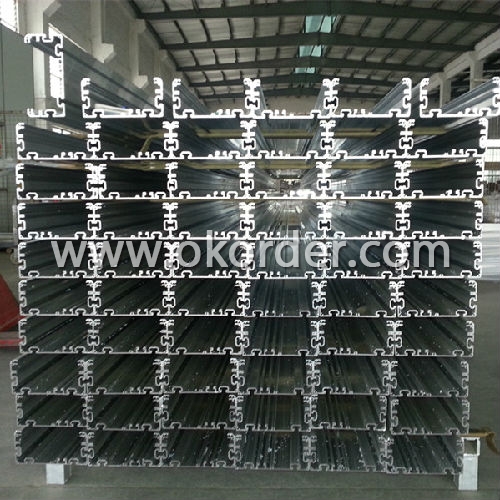

Aluminium Profile for Industry

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of aluminium Profile for Industry

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of aluminium Profile for Industry

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of aluminium Profile for Industry

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of aluminium Profile for Industry

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q:What is aluminum profile opening mold, I want to process a batch of aluminum profiles, the other side to open mold fees also expensive, then I can open the mold of things? I don't know the hero for a favor

- Aluminum production process is actually like toothpaste, the liquid aluminum from a specific shape of the mouth squeezed out, cool after becoming a profile, mold that is to do that exit......

- Q:What are the weight limitations of aluminum profiles?

- The weight limitations of aluminum profiles depend on various factors such as the dimensions, shape, and structural integrity of the profile itself. Aluminum profiles are generally lightweight and have a high strength-to-weight ratio, making them suitable for a wide range of applications. However, the maximum weight capacity will vary depending on the specific profile design and the intended use. Aluminum profiles can typically support a significant amount of weight, especially when they are properly engineered and reinforced. For simple structural applications, such as framing or support systems, aluminum profiles can handle loads ranging from a few hundred pounds to several thousand pounds. These profiles are commonly used in industries like construction, automotive, aerospace, and manufacturing. It is important to note that the load-bearing capacity of aluminum profiles can be enhanced through various techniques, such as increasing the thickness or adding reinforcing elements like gussets or braces. These modifications help to distribute the weight and improve the overall strength of the profile. Additionally, it is crucial to consider other factors such as the length of the profile, the type of connection or fastening method used, and the overall stability of the structure. These factors can affect the weight limitations and overall structural integrity of the aluminum profiles. To determine the specific weight limitations of aluminum profiles for a particular application, it is recommended to consult with a structural engineer or refer to the technical specifications provided by the manufacturer.

- Q:Which price is expensive for aluminum profiles 6063-T6 and 6063-T5?

- 2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy.0: watch master alloy1: table primary alloy is modified by the first timeThe original alloy of table 2: has been modified second times2.3, third, and four digits:Pure aluminum: represents the original alloyAlloy: the designation of individual alloys"- >: the later Hn or Tn indicates the condition of the work hardening or the symbol of the heat treatment state-Hn: indicating the symbol of temper of non heat treated alloys-Tn: the symbol of temper of heat treated alloysT5It is cooled by a high temperature molding process and then artificially aged. The utility model is suitable for the artificial aging product after being cooled by the high temperature forming process without being cold processed (which can be straightened and straightened without affecting the mechanical performance limit).

- Q:How do you install aluminum profiles?

- Follow these instructions for installing aluminum profiles: 1. Begin by measuring and cutting the profiles to the desired length using a saw equipped with a fine-tooth blade. It is essential to wear safety goggles and gloves during the cutting process. 2. Prior to installation, ensure the surface where the profiles will be placed is thoroughly cleaned. Remove any dirt, dust, or debris that could interfere with the installation. 3. Apply adhesive or silicone sealant to the back of the profile to securely attach it to the surface and create a watertight seal. 4. Position the profile on the surface and firmly press it down to guarantee proper adhesion. Utilize a level to ensure it is straight and correctly aligned. 5. If needed, utilize screws or fasteners to further secure the profile to the surface. Pre-drill pilot holes to prevent any cracking of the aluminum. 6. Repeat this process for each profile, leaving a small gap between them to account for expansion and contraction. 7. Once all profiles are installed, remove any excess adhesive or sealant. Use a damp cloth or sponge to wipe away any residue. 8. Allow the profiles to fully cure according to the manufacturer's instructions before applying any additional finishes or utilizing the area. Always consult the manufacturer's instructions for specific installation guidelines and recommendations.

- Q:How do you ensure proper alignment and accuracy when using aluminum profiles?

- To ensure proper alignment and accuracy when using aluminum profiles, there are several important steps that can be followed: 1. Start by selecting high-quality aluminum profiles that are manufactured with precision and have uniform dimensions. This will minimize any variations in the profiles and make it easier to achieve accurate alignments. 2. Before starting any assembly, thoroughly clean the surfaces of the profiles and any connecting elements such as brackets or connectors. This will remove any dirt, dust, or debris that could interfere with the alignment process. 3. Use accurate measuring tools such as rulers, calipers, or laser levels to precisely measure and mark the desired positions for the profiles. This will ensure that the profiles are aligned correctly from the start. 4. When connecting or joining multiple profiles, make use of alignment aids such as alignment pins or clamps. These aids can help hold the profiles in place while adjustments are made to achieve proper alignment. 5. Take the time to carefully check and adjust the alignment at multiple points along the length of the profiles. This will help identify any inconsistencies or misalignments that may have occurred during the assembly process. 6. Double-check all measurements and alignments before finalizing any connections or fixing the profiles in place. This will help avoid any potential issues or errors that could arise later on. 7. If necessary, make use of shims or spacers to fine-tune the alignment. These small adjustments can help compensate for any slight variations or inconsistencies in the profiles or the installation surface. 8. Finally, ensure that all connections and fasteners are tightened securely but not excessively. Over-tightening can lead to misalignments or distortions, while loose connections can compromise the integrity and accuracy of the assembly. By following these steps and paying attention to detail, it is possible to achieve proper alignment and accuracy when using aluminum profiles. This will result in a sturdy and precise structure that meets the desired specifications.

- Q:How do you calculate the weight-bearing capacity of aluminum profiles?

- To calculate the weight-bearing capacity of aluminum profiles, you need to consider various factors such as the dimensions of the profile, the material grade of aluminum used, and the specific application requirements. Firstly, determine the dimensions of the aluminum profile, including the length, width, and thickness. These measurements will help you calculate the cross-sectional area of the profile, which is a crucial parameter in determining its load-bearing capacity. Next, consider the material grade of aluminum used in the profile. Aluminum alloys have different strength properties, so it is essential to know the specific alloy and temper designation. This information can be obtained from the manufacturer or supplier. Once you have the cross-sectional area and material grade, you can refer to engineering standards or handbooks that provide load tables or formulas for calculating the safe load capacity of aluminum profiles. These resources usually provide a range of load ratings based on different loading conditions, such as static or dynamic loads, and factors like span length, support conditions, and safety factors. It is crucial to consider the specific application requirements and any additional factors that may affect the load-bearing capacity, such as temperature, vibration, or potential impact forces. These factors may require further adjustments to the calculated load capacity. Additionally, consulting with a structural engineer or an aluminum profile manufacturer can provide valuable insights and recommendations for calculating the weight-bearing capacity more accurately. They may have specialized knowledge or testing data specific to the aluminum profile in question, ensuring a more reliable calculation. Overall, calculating the weight-bearing capacity of aluminum profiles involves considering the dimensions, material grade, specific application requirements, and consulting relevant resources or experts in the field to ensure accurate and safe load calculations.

- Q:The 50 series and the 60 series of aluminum profiles, which one is good?

- Of course, 60 of the good.60 and 50 refers to profiles, from the indoor to outdoor overall thickness of 60MM and 50MM.

- Q:Can aluminum profiles be used in food-grade applications?

- Yes, aluminum profiles can be used in food-grade applications. Aluminum is a non-toxic, lightweight, and corrosion-resistant metal that is commonly used in the food industry. It is often used to fabricate food processing equipment, such as conveyor systems, tanks, shelves, and frames. Aluminum profiles can also be used in the construction of cleanrooms and other sanitary environments where food is processed or stored. Additionally, aluminum is easily cleaned and sanitized, making it a suitable material for food-grade applications. However, it is important to ensure that the aluminum profiles used are specifically designed for food-grade applications and comply with relevant regulations and standards to ensure the safety and quality of the food being processed or stored.

- Q:How much is the 5000 ton aluminum profile extrusion machine? What section can I have?

- 5000 tons press, plus auxiliary machine, installed finished, almost 50 million -1 million, this depends on the configuration. Cheap certainly also domestic, but a penny a cent goods.A general can reach the maximum about 400mm.

- Q:How do I maintain and clean aluminum profiles?

- Achieving and upholding the cleanliness and maintenance of aluminum profiles can be accomplished by adhering to the following guidelines: 1. Consistent dusting is key: Commence by employing a gentle cloth or feather duster to eliminate loose dust or dirt. This will hinder the accumulation of grime and simplify the subsequent cleaning process. 2. Create a cleaning solution: Combine warm water with a mild detergent or dish soap in either a bucket or spray bottle. It is important to avoid the usage of harsh chemicals or abrasive cleaners, as they have the potential to cause damage to the aluminum surface. 3. Thoroughly clean the profiles: Immerse a soft cloth or sponge into the cleaning solution and delicately scrub the aluminum profiles. Particular attention should be given to areas that exhibit stains or stubborn dirt. 4. Rinse with fresh water: Subsequent to cleaning, it is crucial to thoroughly rinse the profiles with clean water to eliminate any residual soap or cleaning solution. This step is essential in preventing the formation of streaks or marks caused by dried residue. 5. Dry the profiles: Employ a soft, dry cloth or towel to meticulously wipe the aluminum profiles until they are completely dry. This will help prevent the formation of water spots and preserve the metallic shine. 6. Optional polishing: If desired, a non-abrasive aluminum polish can be applied to further enhance the shine and safeguard the surface. For optimal results, adhere to the instructions provided on the polish packaging. 7. Regular upkeep: In order to maintain the aluminum profiles in excellent condition, it is imperative to engage in regular maintenance practices. This includes consistent dusting, avoiding the usage of abrasive materials or cleaners, and promptly addressing any stains or spills. By adhering to these steps, you can effectively maintain and clean aluminum profiles, thereby ensuring that they retain their pristine appearance for extended periods of time.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminium Profile for Industry

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords