All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are anodized aluminum profiles used to achieve specific architectural aesthetics in construction?

Anodized aluminum profiles are commonly used in construction to achieve specific architectural aesthetics due to their unique properties. The anodization process involves creating a protective oxide layer on the surface of the aluminum, resulting in increased durability, corrosion resistance, and the ability to retain color for extended periods. This makes anodized aluminum profiles an ideal choice for architectural elements such as window frames, curtain walls, and decorative features. The anodized finish can be customized to achieve various colors, textures, and gloss levels, allowing architects and designers to create visually appealing structures that blend seamlessly with the overall aesthetic of the building. Additionally, anodized aluminum profiles can be easily fabricated into different shapes, sizes, and designs, offering flexibility and versatility in architectural applications. Overall, the use of anodized aluminum profiles in construction plays a crucial role in achieving specific architectural aesthetics by providing a durable, visually pleasing, and customizable solution.

What are the key factors to consider when selecting a reliable supplier or manufacturer for aluminum profiles?

When selecting a reliable supplier or manufacturer for aluminum profiles, there are a few key factors to consider. Firstly, it is important to assess the supplier's reputation and experience in the industry. Look for suppliers with a proven track record of delivering high-quality products and meeting customer expectations. Additionally, consider the supplier's production capacity and ability to meet your specific requirements in terms of quantity and timelines. It is crucial to evaluate the supplier's quality control measures and certifications to ensure that they adhere to industry standards. Lastly, pricing and cost competitiveness should also be taken into account while balancing it with the supplier's ability to provide consistent quality.

How are aluminum profiles used in the production of machine enclosures to ensure safety?

Aluminum profiles are commonly used in the production of machine enclosures to ensure safety due to their inherent properties. These profiles provide a sturdy and durable framework for the enclosure, offering protection against potential hazards such as impact, vibration, and electromagnetic interference. Additionally, aluminum profiles can be easily customized and assembled, allowing for the incorporation of safety features like locking mechanisms, access panels, and ventilation systems. The lightweight nature of aluminum profiles also facilitates easier transportation and installation of the machine enclosures, ensuring efficient and safe operations.

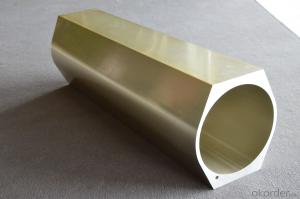

How are aluminum profiles fabricated or manufactured?

Aluminum profiles are typically fabricated or manufactured through a process called extrusion. This involves heating aluminum billets and forcing them through a shaped die using high pressure. The aluminum is then cooled and cut into desired lengths. Additional fabrication processes such as machining, bending, welding, or surface treatments may be applied to achieve specific shapes, sizes, or finishes.

Wholesale Aluminum Profiles from supplier in Liberia

Whether you are a contractor, builder, or developer, our team of experts is ready to assist you in finding the perfect aluminum profiles for your specific needs. We understand the importance of quality and durability in construction projects, which is why we only offer aluminum profiles that meet the highest industry standards.

Our sales team is dedicated to providing exceptional customer service and will work closely with you to understand your requirements and provide personalized solutions. We offer competitive pricing and flexible payment options to ensure that your procurement process is both cost-effective and convenient.

In addition to sales, we also provide comprehensive quotation services, allowing you to easily compare prices and make informed decisions. Our technical support team is available to answer any questions you may have about our aluminum profiles, helping you choose the right products for your projects.

As part of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and manufacturers, ensuring that we can meet your requirements efficiently and effectively. We can handle large orders and offer timely delivery to ensure that your projects stay on schedule.

With our years of experience operating in Liberia, we have developed a deep understanding of the local market and its unique challenges. We can offer valuable insights and expertise to help you navigate the procurement process and ensure the success of your projects. We are committed to building long-term partnerships with our clients and providing ongoing support throughout the entire project lifecycle.

Contact us today to learn more about our aluminum profiles and how we can assist you with your procurement needs in Liberia.

Our sales team is dedicated to providing exceptional customer service and will work closely with you to understand your requirements and provide personalized solutions. We offer competitive pricing and flexible payment options to ensure that your procurement process is both cost-effective and convenient.

In addition to sales, we also provide comprehensive quotation services, allowing you to easily compare prices and make informed decisions. Our technical support team is available to answer any questions you may have about our aluminum profiles, helping you choose the right products for your projects.

As part of CNBM, one of the world's largest building materials companies, we have access to a vast network of suppliers and manufacturers, ensuring that we can meet your requirements efficiently and effectively. We can handle large orders and offer timely delivery to ensure that your projects stay on schedule.

With our years of experience operating in Liberia, we have developed a deep understanding of the local market and its unique challenges. We can offer valuable insights and expertise to help you navigate the procurement process and ensure the success of your projects. We are committed to building long-term partnerships with our clients and providing ongoing support throughout the entire project lifecycle.

Contact us today to learn more about our aluminum profiles and how we can assist you with your procurement needs in Liberia.