All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

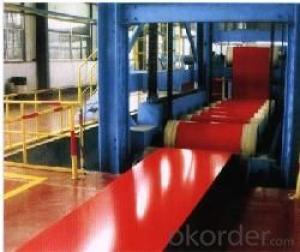

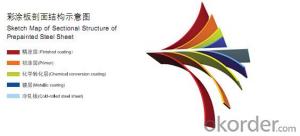

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the safety considerations for handling and storing steel strips?

The safety considerations for handling and storing steel strips include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against cuts, eye injuries, and foot injuries. It is important to use proper lifting techniques to prevent back injuries and muscle strains. Steel strips should be stored in a well-organized and secure manner, with proper support and bracing to prevent them from falling or shifting. Additionally, caution should be exercised when using tools or equipment to handle steel strips to avoid accidental injuries.

How are steel strips integrated into the aerospace industry for aircraft components?

Steel strips are integrated into the aerospace industry for aircraft components through various manufacturing processes. These strips are utilized for their high strength and durability, making them suitable for critical applications in aircraft structures. They are commonly used in the fabrication of wing and fuselage panels, as well as in landing gear systems. Steel strips are cut, shaped, and formed into desired shapes using specialized machinery and techniques. These components are then further processed and assembled to meet the stringent quality and safety standards of the aerospace industry.

How are steel strips applied in the creation of high-tensile cables and ropes for bridge construction and maintenance?

Steel strips are applied in the creation of high-tensile cables and ropes for bridge construction and maintenance by being tightly wound together to form a strong and durable core. This core is then coated with protective layers to enhance its resistance to corrosion and wear, making it suitable for withstanding heavy loads and harsh environmental conditions. The steel strips provide the necessary strength and flexibility, ensuring the cables and ropes can support the weight of the bridge and withstand the stresses and strains during construction and maintenance activities.

How are steel strips manufactured?

Steel strips are manufactured through a process called hot rolling, where steel billets are heated and passed through a series of rollers to achieve the desired thickness and shape. The heat and pressure applied during this process help to shape the steel into flat strips, which can then be further processed or used in various applications.

Wholesale Steel Strips from supplier in Liberia

Our team of professionals is committed to delivering exceptional customer service and ensuring that your experience with us is seamless and hassle-free. We understand the importance of timely delivery and strive to provide prompt and reliable shipping services for all orders. Additionally, we offer competitive pricing for our Steel Strips products, making us a cost-effective solution for your procurement needs.

In addition to our product offerings, we also provide technical support and guidance to assist you in selecting the right Steel Strips products for your specific applications. Our knowledgeable team is always ready to answer any questions you may have and provide valuable insights to help you make informed decisions.

At our company, we prioritize building long-term relationships with our customers based on trust, reliability, and mutual success. We are dedicated to exceeding your expectations and being your preferred supplier for Steel Strips in Liberia.

Contact us today to discuss your Steel Strips requirements and let us provide you with a tailored solution that meets your needs. We look forward to working with you and supporting your business ventures in Liberia.

In addition to our product offerings, we also provide technical support and guidance to assist you in selecting the right Steel Strips products for your specific applications. Our knowledgeable team is always ready to answer any questions you may have and provide valuable insights to help you make informed decisions.

At our company, we prioritize building long-term relationships with our customers based on trust, reliability, and mutual success. We are dedicated to exceeding your expectations and being your preferred supplier for Steel Strips in Liberia.

Contact us today to discuss your Steel Strips requirements and let us provide you with a tailored solution that meets your needs. We look forward to working with you and supporting your business ventures in Liberia.