All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can welded steel pipes be used for offshore testing facilities?

Yes, welded steel pipes can be used for offshore testing facilities. Welded steel pipes are commonly used in offshore applications due to their strength, durability, and resistance to corrosion. They are suitable for transporting fluids, gases, and other materials in harsh offshore environments. Additionally, welded steel pipes can be customized to meet specific project requirements, making them a reliable choice for offshore testing facilities.

Can welded steel pipe be used for fire protection systems?

Yes, welded steel pipe can be used for fire protection systems. Welded steel pipe is commonly used in fire sprinkler systems due to its durability, strength, and resistance to high temperatures. It can effectively transport water or fire extinguishing agents to control and suppress fires in buildings.

What are the considerations for selecting the appropriate coating for welded steel pipes?

When selecting the appropriate coating for welded steel pipes, several considerations should be taken into account. First and foremost, the coating should provide effective corrosion protection to prevent the pipes from rusting and deteriorating over time. The environment in which the pipes will be used is also crucial, as different coatings may be required for varying conditions such as exposure to saltwater, chemicals, or extreme temperatures. Additionally, factors like the expected lifespan of the pipes, cost, ease of application, and maintenance requirements should be evaluated to ensure the chosen coating meets the specific needs of the project.

Can different types of steel be welded together to make a welded steel pipe?

Yes, different types of steel can be welded together to make a welded steel pipe through a process called dissimilar metal welding. However, it requires careful selection of welding procedures and materials to ensure compatibility and maintain the desired quality and strength of the pipe.

How is the dimensional tolerance of welded steel pipe specified?

The dimensional tolerance of welded steel pipe is typically specified according to the applicable industry standards, such as the American Society for Testing and Materials (ASTM) or the American Welding Society (AWS). These standards provide specific guidelines for measuring and controlling the dimensions of the pipe, including its outside diameter, wall thickness, and length. The tolerance limits are defined to ensure that the welded steel pipe meets the required specifications and can be safely used in various applications.

Wholesale Welded Steel Pipe from supplier in Liberia

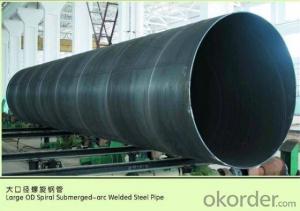

Our team of experts is dedicated to understanding your specific requirements and providing the most suitable Welded Steel Pipe solutions for your projects. We offer a wide range of products including ERW (Electric Resistance Welded) pipes, LSAW (Longitudinal Submerged Arc Welded) pipes, and SSAW (Spiral Submerged Arc Welded) pipes, among others.

In addition to our product offerings, we also provide sales and quotation services, ensuring that you receive competitive pricing for your Welded Steel Pipe needs. Our technical support team is available to assist you throughout the entire process, from product selection to installation, ensuring that your project runs smoothly.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise, allowing us to provide comprehensive solutions for Welded Steel Pipe procurement in Liberia. Our strong market presence and understanding of the local industry enable us to offer valuable insights and guidance for your projects.

Whether you are working on infrastructure development, construction, or any other industry that requires Welded Steel Pipe solutions, we are here to assist you. Contact us today to discuss your requirements and let us provide you with the best possible Welded Steel Pipe solutions in Liberia.

In addition to our product offerings, we also provide sales and quotation services, ensuring that you receive competitive pricing for your Welded Steel Pipe needs. Our technical support team is available to assist you throughout the entire process, from product selection to installation, ensuring that your project runs smoothly.

As a subsidiary of CNBM, we have access to a vast network of resources and expertise, allowing us to provide comprehensive solutions for Welded Steel Pipe procurement in Liberia. Our strong market presence and understanding of the local industry enable us to offer valuable insights and guidance for your projects.

Whether you are working on infrastructure development, construction, or any other industry that requires Welded Steel Pipe solutions, we are here to assist you. Contact us today to discuss your requirements and let us provide you with the best possible Welded Steel Pipe solutions in Liberia.