All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

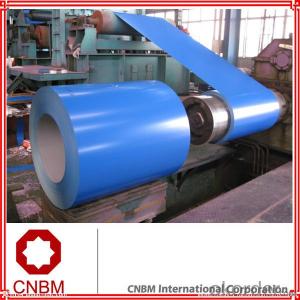

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is coil edge quality maintained during the production of electrical wiring components?

Coil edge quality is maintained during the production of electrical wiring components through various measures. Firstly, the manufacturing process involves using high-quality raw materials that are specifically chosen for their durability and resistance to wear and tear. This ensures that the coil edges remain intact and do not get damaged easily.

Additionally, precision machinery and advanced production techniques are employed to ensure accurate cutting and shaping of the coils. This helps in maintaining consistent and smooth edges, minimizing the chances of any defects or irregularities.

Quality control procedures are also implemented throughout the production process. This includes regular inspections and testing of the coil edges to identify any potential issues and ensure they meet the required specifications. Any defective coils are promptly rejected or repaired to maintain the overall quality.

Furthermore, proper handling and storage of the coils are crucial to prevent any physical damage or deformation. Adequate packaging and transportation procedures are followed to minimize the risk of coil edge damage during transit.

Overall, a combination of high-quality materials, precision manufacturing techniques, stringent quality control measures, and careful handling ensures the maintenance of coil edge quality during the production of electrical wiring components.

What are the challenges in producing high-strength steel coils for structural applications?

Producing high-strength steel coils for structural applications poses several challenges. Firstly, achieving the desired strength requires precise control over the composition and microstructure of the steel, which demands advanced metallurgical techniques. Secondly, the manufacturing process needs to ensure uniformity and consistency in the mechanical properties of the coils, which can be difficult to achieve due to variations in cooling rates and deformation during rolling. Additionally, the high-strength steel can be more susceptible to cracking and distortion, necessitating careful handling and processing techniques. Finally, the cost of producing high-strength steel coils is often higher due to the specialized materials and techniques involved, making it a financial challenge for manufacturers.

What is the role of coil end treatment in preventing welding defects?

The role of coil end treatment in preventing welding defects is to remove any surface contaminants, such as oil or dirt, from the coil ends before they are welded. This ensures a clean and smooth surface for the welding process, which helps to prevent defects such as porosity or lack of fusion. Additionally, coil end treatment can also involve trimming or chamfering the ends to improve the weldability and reduce the risk of defects. Overall, this treatment plays a crucial role in ensuring high-quality welds and reducing the likelihood of welding defects.

Wholesale Steel Coils from supplier in Eritrea

We are a Steel Coils supplier serving the Eritrea, mainly engaged in the sale, quotation, and technical support services of various Steel Coils products in the Eritrea region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Coils procurement services in the Eritrea. Not only do we have a wide range of Steel Coils products, but after years of market development in the Eritrea, we can also provide valuable experience for your projects.