All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

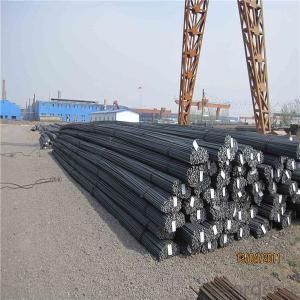

- - Steel Rebars

- - Steel Strips

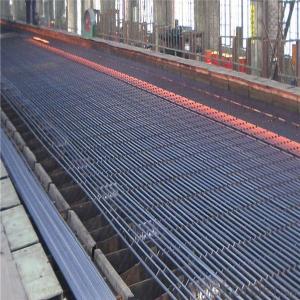

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of coated, encapsulated, and epoxy-coated steel rebars in projects with stringent corrosion protection requirements?

The role of coated, encapsulated, and epoxy-coated steel rebars in projects with stringent corrosion protection requirements is to provide an additional layer of protection against corrosion. These coating technologies create a barrier between the steel rebar and the surrounding environment, preventing moisture, chemicals, and other corrosive agents from reaching the steel surface. This helps to extend the lifespan of the structure, reduce maintenance costs, and ensure the structural integrity of the project.

What is the role of tie beam in relation to steel rebars?

The role of a tie beam in relation to steel rebars is to provide additional structural support and stability. The tie beam is typically made of reinforced concrete and is connected to the steel rebars to distribute the load and prevent excessive deflection or movement in the structure. It helps to strengthen the overall framework and prevent any potential failure or collapse.

What is the significance of development splices in achieving secure and durable steel rebar connections?

Development splices are crucial in achieving secure and durable steel rebar connections as they ensure the structural integrity and strength of reinforced concrete structures. These splices allow for the transfer of loads between adjacent steel bars, effectively distributing the forces and preventing potential failure points. By creating a continuous and reliable connection, development splices enhance the overall stability and longevity of the construction, ensuring it can withstand various external factors such as seismic activities or heavy loads.

What are the safety precautions for cutting and bending steel rebars?

When cutting and bending steel rebars, it is important to follow a few safety precautions to prevent accidents and injuries. These precautions include wearing appropriate personal protective equipment such as safety glasses, gloves, and a hard hat to protect against flying debris and head injuries. It is crucial to use the correct tools for cutting and bending, such as a rebar cutter or a hydraulic bender, and ensure they are in good working condition. Additionally, maintaining a clean and organized work area, securing the rebar firmly to prevent movement, and never standing in the path of the cutting or bending action are essential safety measures. Lastly, it is recommended to receive proper training and follow the manufacturer's instructions and guidelines to minimize the risks associated with cutting and bending steel rebars.

Wholesale Steel Rebars from supplier in Eritrea

We are a Steel Rebars supplier serving the Eritrea, mainly engaged in the sale, quotation, and technical support services of various Steel Rebars products in the Eritrea region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Steel Rebars procurement services in the Eritrea. Not only do we have a wide range of Steel Rebars products, but after years of market development in the Eritrea, we can also provide valuable experience for your projects.