All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are aluminum profiles tested for load-bearing capabilities in structural applications?

Aluminum profiles are typically tested for load-bearing capabilities in structural applications through various methods such as static load testing, fatigue testing, and finite element analysis (FEA). Static load testing involves subjecting the profiles to gradually increasing loads until failure occurs, allowing engineers to determine their maximum load capacity. Fatigue testing involves applying cyclic loads to simulate real-life conditions and observe the profiles' ability to withstand repeated stress without failure. FEA is a computer-based analysis that uses mathematical models to simulate and predict the behavior of aluminum profiles under different loads, helping engineers optimize their design and ensure their load-bearing capabilities. These testing methods ensure that aluminum profiles meet safety standards and can support the required loads in structural applications.

How are aluminum profiles used in the development of efficient and customizable conveyor and material handling systems?

Aluminum profiles are used in the development of efficient and customizable conveyor and material handling systems due to their lightweight yet sturdy nature. These profiles allow for easy assembly and modification, making it possible to create conveyor systems tailored to specific needs. Additionally, aluminum profiles offer excellent corrosion resistance, ensuring the longevity of the conveyor systems in various environments. Their versatility and adaptability make them a preferred choice for constructing efficient and customizable conveyor and material handling systems.

How do you ensure the compatibility of accessories and components with aluminum profiles?

To ensure the compatibility of accessories and components with aluminum profiles, it is important to consider factors such as the dimensions, tolerances, and mounting options of the profiles. It is essential to choose accessories and components that are specifically designed to fit with aluminum profiles, ensuring a secure and stable connection. Additionally, checking for compatibility through technical specifications, consulting with manufacturers, and conducting thorough testing can further ensure a proper fit and functionality.

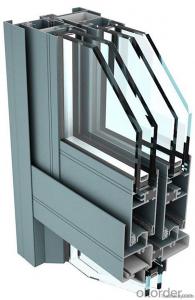

What are the different surface finishes available for aluminum profiles?

There are several different surface finishes available for aluminum profiles including anodizing, powder coating, polishing, brushing, and sandblasting.

Wholesale Aluminum Profiles from supplier in Comoros

We are a Aluminum Profiles supplier serving the Comoros, mainly engaged in the sale, quotation, and technical support services of various Aluminum Profiles products in the Comoros region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Profiles procurement services in the Comoros. Not only do we have a wide range of Aluminum Profiles products, but after years of market development in the Comoros, we can also provide valuable experience for your projects.