All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the role of aluminum coils in the production of aluminum roofing materials?

The role of aluminum coils in the production of aluminum roofing materials is to provide a continuous and uniform sheet of aluminum that can be shaped, cut, and manipulated into the desired roofing product. These coils act as the base material from which the roofing panels are formed, ensuring durability, strength, and resistance to corrosion for long-lasting and high-quality roofs.

What are the applications of aluminum coils in the aircraft industry?

Aluminum coils have various applications in the aircraft industry. They are commonly used in the construction of aircraft structures, such as aircraft wings, fuselages, and tail sections. The lightweight nature of aluminum makes it an ideal material for these components as it helps reduce the overall weight of the aircraft, enhancing fuel efficiency and performance. Additionally, aluminum coils are also utilized in the manufacturing of heat exchangers, air conditioning systems, and electrical wiring systems within aircraft, ensuring efficient cooling, climate control, and power distribution.

How are aluminum coils prepped for the roll forming process?

Aluminum coils are prepped for the roll forming process through a series of steps. Firstly, the coils are uncoiled and flattened to remove any bends or kinks. Then, the surface of the coils is cleaned and degreased to ensure proper adhesion of any coatings or paints. After that, the coils are treated with a chemical solution to promote better paint adhesion and prevent corrosion. Finally, the coils are dried and inspected for any defects before they are ready for the roll forming process.

How are aluminum coils manufactured?

Aluminum coils are manufactured through a process called continuous casting and rolling. In this process, molten aluminum is poured into a caster, which produces a continuous strip or slab of aluminum. This strip is then rolled and cooled to achieve the desired thickness, width, and mechanical properties. The rolling process may involve multiple passes through various rolling mills to achieve the desired final thickness. The coils are then coiled and packaged for further processing or distribution.

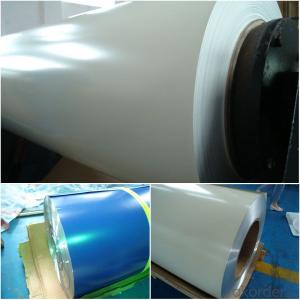

Wholesale Aluminum Coils from supplier in Nigeria

Whether you are in need of Aluminum Coils for construction, manufacturing, or any other application, we have you covered. Our Aluminum Coils are sourced from trusted manufacturers and undergo rigorous quality control to ensure that they meet international standards.

We understand the unique requirements and challenges of the Nigerian market, and we strive to provide tailored solutions to meet your specific needs. Our team of experts is well-versed in local regulations and industry trends, allowing us to offer valuable advice and guidance throughout the procurement process.

In addition to supplying high-quality Aluminum Coils, we also provide a range of value-added services, such as custom cutting, slitting, and packaging. We can accommodate both small and large orders, ensuring timely delivery and competitive pricing.

At our company, customer satisfaction is our top priority. We pride ourselves on our responsive and efficient customer support, ensuring that all inquiries and requests are handled promptly and professionally. Whether you need assistance with product selection, technical specifications, or pricing, our team is here to help.

Partnering with us means gaining access to a reliable and trusted supplier of Aluminum Coils in Nigeria. Contact us today to discuss your requirements and let us provide you with the best solutions for your project.

We understand the unique requirements and challenges of the Nigerian market, and we strive to provide tailored solutions to meet your specific needs. Our team of experts is well-versed in local regulations and industry trends, allowing us to offer valuable advice and guidance throughout the procurement process.

In addition to supplying high-quality Aluminum Coils, we also provide a range of value-added services, such as custom cutting, slitting, and packaging. We can accommodate both small and large orders, ensuring timely delivery and competitive pricing.

At our company, customer satisfaction is our top priority. We pride ourselves on our responsive and efficient customer support, ensuring that all inquiries and requests are handled promptly and professionally. Whether you need assistance with product selection, technical specifications, or pricing, our team is here to help.

Partnering with us means gaining access to a reliable and trusted supplier of Aluminum Coils in Nigeria. Contact us today to discuss your requirements and let us provide you with the best solutions for your project.