All Categories

- - Steel Wire Rod

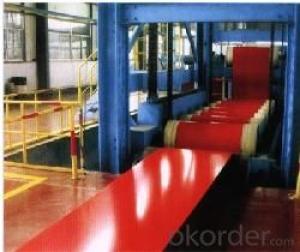

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do steel coil properties change when used in the construction of household appliances?

When steel coils are used in the construction of household appliances, their properties may change in several ways. First, the strength and durability of the steel coil may be enhanced to ensure it can withstand the demands of the appliance's usage. This could involve increasing the tensile strength or hardness of the steel. Additionally, the steel coil may undergo surface treatments such as galvanization or coating to enhance its resistance to corrosion, which is crucial in household appliances exposed to moisture or harsh environments. Finally, the dimensions and shape of the steel coil may be modified to fit specific appliance designs, ensuring optimal functionality and integration. Overall, the usage of steel coils in household appliances involves tailoring their properties to meet the unique requirements of these applications.

How are steel coils prepared for use in the construction of bridges and infrastructure?

Steel coils are prepared for use in the construction of bridges and infrastructure through a series of steps. First, the coils are uncoiled and straightened to remove any bends or twists. Then, they undergo a process called leveling, where the steel is passed through rollers to achieve a flat surface. Next, the steel is cut into required lengths and widths using shearing or slitting machines. After that, the edges of the steel are trimmed and any burrs or imperfections are removed. Finally, the coils are either stored or transported to the construction site, where they are further processed or used directly in the construction of bridges and infrastructure.

What is the impact of coil defects on downstream processes?

Coil defects can have a significant impact on downstream processes. These defects can include imperfections such as uneven winding, surface irregularities, or mechanical damage. These issues can lead to difficulties in unwinding the coil, causing production delays and increased downtime. Furthermore, defects can also affect the quality of the finished product, resulting in rejections or customer complaints. To mitigate these impacts, thorough inspection and quality control measures should be implemented to identify and address coil defects before they reach downstream processes.

Wholesale Steel Coils from supplier in Nigeria

With a focus on supplying Steel Coils in Nigeria, we are dedicated to meeting your specific needs with our comprehensive range of products and services. As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to offer efficient and reliable procurement services for Steel Coils in Nigeria.

Our extensive product portfolio ensures that you have a wide selection of Steel Coils to choose from, allowing you to find the perfect fit for your projects. Additionally, our years of experience in the Nigerian market give us valuable insights and support to assist you in making informed decisions.

Whether you need sales assistance, quotations, or technical guidance, our team is here to provide you with the support you need at every step of the process. We strive to be your trusted partner for all your Steel Coils requirements in Nigeria. Trust us to deliver the quality and reliability you expect.

Our extensive product portfolio ensures that you have a wide selection of Steel Coils to choose from, allowing you to find the perfect fit for your projects. Additionally, our years of experience in the Nigerian market give us valuable insights and support to assist you in making informed decisions.

Whether you need sales assistance, quotations, or technical guidance, our team is here to provide you with the support you need at every step of the process. We strive to be your trusted partner for all your Steel Coils requirements in Nigeria. Trust us to deliver the quality and reliability you expect.