All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

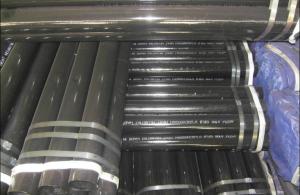

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different types of welding processes used for welding steel pipes?

The different types of welding processes used for welding steel pipes include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), gas tungsten arc welding (GTAW), and submerged arc welding (SAW).

Can welded steel pipes be used for staircases?

Yes, welded steel pipes can be used for staircases. Welded steel pipes are durable, strong, and can support heavy loads, making them suitable for constructing staircases. Additionally, their sleek and modern appearance can enhance the overall aesthetic of the staircase design.

How do you calculate the required spacing between pipe hangers for a welded steel pipe?

To calculate the required spacing between pipe hangers for a welded steel pipe, you need to consider several factors. These include the pipe size, material, operating temperature, weight, and the type of hanger being used. The general guideline is to space the hangers at intervals that prevent excessive sagging or bending of the pipe while providing adequate support. It is recommended to consult relevant industry standards or guidelines and consider the specific requirements of the installation to ensure proper spacing and support for the welded steel pipe.

How are welded steel pipes insulated in cold weather conditions?

In cold weather conditions, welded steel pipes are typically insulated using various methods. One common method is to use thermal insulation materials such as foam or mineral wool. These materials are wrapped around the pipes to create a protective layer that helps minimize heat loss and prevent the pipes from freezing. Additionally, an outer jacket or weather-resistant covering is often applied to provide further insulation and protect the pipes from external elements. This insulation helps maintain the temperature of the pipes, preventing any potential damage or operational issues caused by extremely low temperatures.

Wholesale Welded Steel Pipe from supplier in Nigeria

Whether you require Welded Steel Pipes for construction, infrastructure, oil and gas, or any other industry, we have the capabilities to meet your specific requirements. Our range of products includes various sizes, grades, and specifications to ensure that we can provide the right solution for your project.

When you choose us as your supplier, you can expect excellent customer service and support throughout the procurement process. Our team of experienced professionals is ready to assist you with sales inquiries, quotations, and technical support. We understand the importance of timely and accurate information, and we strive to provide you with the necessary details to make informed decisions.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive pricing and reliable delivery to our customers in Nigeria. With our strong network and partnerships, we can source and supply Welded Steel Pipes efficiently, ensuring that your projects stay on schedule.

Over the years, we have built strong relationships with local suppliers, manufacturers, and distributors in Nigeria. This has helped us develop a deep understanding of the local market dynamics and regulations. Our expertise in navigating the Nigerian market enables us to provide tailored solutions that meet your project requirements effectively.

In summary, when you choose us as your supplier of Welded Steel Pipes in Nigeria, you can expect a comprehensive range of products, excellent customer service, competitive pricing, and reliable delivery. Our years of experience and expertise in the Nigerian market make us the ideal partner to support your project needs. Contact us today to discuss your requirements and let us assist you in finding the right solutions for your Welded Steel Pipe procurement in Nigeria.

When you choose us as your supplier, you can expect excellent customer service and support throughout the procurement process. Our team of experienced professionals is ready to assist you with sales inquiries, quotations, and technical support. We understand the importance of timely and accurate information, and we strive to provide you with the necessary details to make informed decisions.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the backing of a reputable and financially stable organization. This allows us to offer competitive pricing and reliable delivery to our customers in Nigeria. With our strong network and partnerships, we can source and supply Welded Steel Pipes efficiently, ensuring that your projects stay on schedule.

Over the years, we have built strong relationships with local suppliers, manufacturers, and distributors in Nigeria. This has helped us develop a deep understanding of the local market dynamics and regulations. Our expertise in navigating the Nigerian market enables us to provide tailored solutions that meet your project requirements effectively.

In summary, when you choose us as your supplier of Welded Steel Pipes in Nigeria, you can expect a comprehensive range of products, excellent customer service, competitive pricing, and reliable delivery. Our years of experience and expertise in the Nigerian market make us the ideal partner to support your project needs. Contact us today to discuss your requirements and let us assist you in finding the right solutions for your Welded Steel Pipe procurement in Nigeria.