All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

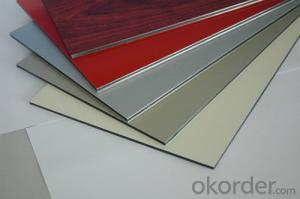

What techniques are used to customize the appearance of aluminum sheets through painting and printing?

There are several techniques used to customize the appearance of aluminum sheets through painting and printing. Some common techniques include screen printing, digital printing, and powder coating. Screen printing involves applying ink through a mesh screen onto the aluminum sheet to create a desired design or pattern. Digital printing utilizes computer technology to directly transfer an image onto the aluminum surface, allowing for detailed and intricate designs. Powder coating involves applying a dry powder onto the aluminum sheet, which is then heated and cured to create a durable and vibrant finish. These techniques provide endless possibilities for customization and personalization of aluminum sheets.

How are aluminum sheets used in the automotive industry to improve fuel efficiency and reduce emissions?

Aluminum sheets are used in the automotive industry to improve fuel efficiency and reduce emissions through their lightweight properties. By replacing heavier materials, such as steel, with lightweight aluminum sheets, vehicles can be made lighter, resulting in improved fuel efficiency. Additionally, aluminum sheets offer excellent strength and durability, allowing for the design of more aerodynamic and fuel-efficient vehicle structures. This reduction in weight and improved aerodynamics contribute to lower fuel consumption and decreased emissions, making aluminum sheets a crucial component in achieving sustainability goals within the automotive industry.

What is the effect of alloying elements on the machinability of aluminum sheets?

Alloying elements can have both positive and negative effects on the machinability of aluminum sheets. Certain alloying elements, such as copper and magnesium, can improve the strength and hardness of the aluminum, making it more difficult to machine. On the other hand, other alloying elements, like silicon and manganese, can enhance the machinability by reducing the tendency for built-up edge formation and improving chip formation. Therefore, the effect of alloying elements on machinability depends on the specific elements and their concentrations in the aluminum alloy.

Wholesale Aluminum Sheets from supplier in Iraq

Whether you require Aluminum Sheets for construction, automotive, or industrial applications, we have the expertise and resources to fulfill your needs. Our Aluminum Sheets are sourced from reputable manufacturers, ensuring high quality and compliance with international standards.

In addition to our wide range of products, we provide comprehensive sales, quoting, and technical support services. Our team of experienced professionals can assist you in selecting the right Aluminum Sheets for your specific requirements, offer competitive pricing, and provide technical guidance throughout your project.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer convenient and efficient procurement solutions, ensuring timely delivery and competitive prices for Aluminum Sheets in Iraq.

With our extensive market experience, we understand the unique challenges and requirements of the Iraqi market. Our team is well-versed in local regulations and can provide valuable insights and expertise to ensure the success of your projects.

Choose us as your trusted supplier of Aluminum Sheets in Iraq and experience the convenience, efficiency, and quality that we bring to every project. Contact us today to discuss your requirements and benefit from our comprehensive range of products and services.

In addition to our wide range of products, we provide comprehensive sales, quoting, and technical support services. Our team of experienced professionals can assist you in selecting the right Aluminum Sheets for your specific requirements, offer competitive pricing, and provide technical guidance throughout your project.

Being a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources. This enables us to offer convenient and efficient procurement solutions, ensuring timely delivery and competitive prices for Aluminum Sheets in Iraq.

With our extensive market experience, we understand the unique challenges and requirements of the Iraqi market. Our team is well-versed in local regulations and can provide valuable insights and expertise to ensure the success of your projects.

Choose us as your trusted supplier of Aluminum Sheets in Iraq and experience the convenience, efficiency, and quality that we bring to every project. Contact us today to discuss your requirements and benefit from our comprehensive range of products and services.