All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

Can you explain the role of alloying elements in aluminum profile composition?

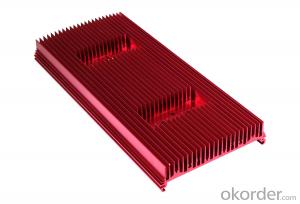

Alloying elements are added to aluminum profiles to enhance their mechanical properties and performance. These elements can include silicon, copper, magnesium, manganese, and zinc. Silicon improves the fluidity and casting properties of aluminum, while copper increases strength and corrosion resistance. Magnesium enhances the strength-to-weight ratio and improves the profile's heat treatability. Manganese improves strength and workability, while zinc improves corrosion resistance. The addition of these alloying elements allows for the customization of aluminum profiles to meet specific application requirements.

What are the considerations for using aluminum profiles in the construction of bridges and infrastructure?

Some considerations for using aluminum profiles in the construction of bridges and infrastructure include:

1. Weight: Aluminum profiles are lightweight, which makes them easier to transport and install. This can lead to cost savings and efficiency in construction projects.

2. Corrosion resistance: Aluminum has a natural oxide layer that protects it from corrosion, making it suitable for outdoor applications where bridges and infrastructure are exposed to elements like rain, humidity, and saltwater.

3. Durability: Aluminum profiles are strong and have a high strength-to-weight ratio, allowing them to withstand heavy loads and structural stresses. This makes them a reliable choice for constructing bridges and infrastructure that need to support significant weight.

4. Design flexibility: Aluminum profiles can be easily shaped and formed into various designs, allowing for flexibility in the construction of bridges and infrastructure. This versatility enables architects and engineers to create innovative and aesthetically pleasing structures.

5. Sustainable material: Aluminum is a highly recyclable material, and using it in construction projects can contribute to sustainability efforts. Recycling aluminum requires significantly less energy compared to producing it from raw materials, making it an environmentally friendly choice.

However, there are also some limitations to using aluminum profiles in bridge and infrastructure construction. Aluminum is not as strong as steel, so it may not be suitable for applications that require extremely high strength. Additionally, its initial cost may be higher compared to other materials, although the long-term benefits such as low maintenance and durability can offset this.

How do you install aluminum profiles for windows and doors?

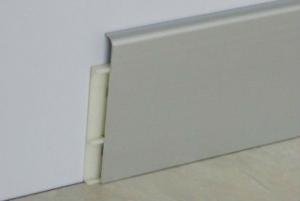

To install aluminum profiles for windows and doors, you will typically begin by measuring and marking the areas where the profiles will be installed. Next, you would drill holes at the marked locations, ensuring they are aligned properly. The profiles are then secured to the window or door frame using screws or nails. It is important to ensure that the profiles are straight and level during installation. Finally, any excess material can be trimmed and the profiles can be caulked or sealed to provide a finished look and improve insulation.

Wholesale Aluminum Profiles from supplier in Ireland

We are a Aluminum Profiles supplier serving the Ireland, mainly engaged in the sale, quotation, and technical support services of various Aluminum Profiles products in the Ireland region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Profiles procurement services in the Ireland. Not only do we have a wide range of Aluminum Profiles products, but after years of market development in the Ireland, we can also provide valuable experience for your projects.