All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

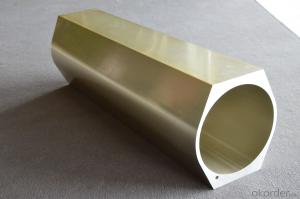

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you prepare and treat aluminum profiles for welding and other fabrication processes?

To prepare and treat aluminum profiles for welding and other fabrication processes, it is essential to follow a few key steps. Firstly, the aluminum surface should be thoroughly cleaned to remove any dirt, grease, or oxidation using a suitable degreaser or solvent. This ensures proper adhesion and prevents contamination during the welding process.

Next, it is recommended to mechanically or chemically etch the aluminum surface to create a roughened texture. This helps promote better welding penetration and improves the overall bond strength. Mechanical methods like sanding or abrasive blasting can be used, or chemical etchants specifically designed for aluminum can be applied.

After the surface preparation, it is crucial to select the appropriate welding technique and filler material based on the specific aluminum alloy being used. Aluminum welding typically requires specialized techniques such as TIG (tungsten inert gas) or MIG (metal inert gas) welding. Careful consideration should also be given to the welding parameters, including current, voltage, and travel speed, to ensure optimal results.

During the fabrication process, it is important to protect the aluminum profiles from contamination, oxidation, or any other potential damage. This can be achieved by using shielding gases, inert atmospheres, or protective coatings. Additionally, proper handling and storage practices should be followed to prevent any physical damage to the profiles.

Overall, a combination of thorough cleaning, surface preparation, suitable welding techniques, and protective measures is essential to prepare and treat aluminum profiles for welding and other fabrication processes effectively.

How are aluminum profiles employed in the production of efficient lighting solutions?

Aluminum profiles are commonly used in the production of efficient lighting solutions due to their lightweight, durable, and versatile nature. These profiles provide a sturdy framework for housing LED modules, power supplies, and other components, ensuring optimal heat dissipation and extending the lifespan of the lighting fixtures. The extruded aluminum profiles also offer design flexibility, allowing for various shapes and sizes to accommodate different lighting requirements. Additionally, aluminum's excellent conductivity properties enable efficient electrical connections, further enhancing the overall efficiency and performance of the lighting solutions.

How do you choose the right aluminum profile supplier or manufacturer?

When choosing the right aluminum profile supplier or manufacturer, it is important to consider several factors. Firstly, evaluate their experience and reputation in the industry. Look for a supplier or manufacturer with a proven track record and positive customer feedback. Additionally, consider their production capabilities and quality control processes to ensure they can meet your specific requirements. It is also crucial to assess their pricing and delivery terms, comparing them with other potential suppliers to ensure competitiveness. Lastly, consider their customer service and support, as a responsive and reliable supplier can greatly enhance your overall purchasing experience.

Wholesale Aluminum Profiles from supplier in Cyprus

We are a Aluminum Profiles supplier serving the Cyprus, mainly engaged in the sale, quotation, and technical support services of various Aluminum Profiles products in the Cyprus region. We are a subsidiary platform of the Fortune Global 500 company CNBM, able to provide you with one-stop Aluminum Profiles procurement services in the Cyprus. Not only do we have a wide range of Aluminum Profiles products, but after years of market development in the Cyprus, we can also provide valuable experience for your projects.