All Categories

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Ceramic Fiber Products

- - Monolithic Refractories

- - Refractory Bricks

- - Raw Materials For Refractory

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the applications of aluminum coils in the production of aluminum light poles?

Aluminum coils are widely used in the production of aluminum light poles due to their lightweight and corrosion-resistant properties. These coils are used to fabricate the cylindrical shape of the light poles, providing structural strength while keeping the overall weight low. Additionally, aluminum coils allow for easy customization and are easily formed into various sizes and shapes, enabling the production of aesthetically appealing and durable light poles.

What is the process of coating aluminum coils for various applications?

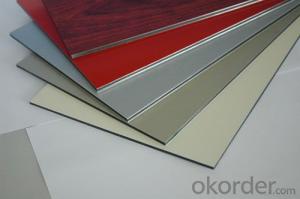

The process of coating aluminum coils for various applications involves several steps. First, the aluminum coils are cleaned to remove any impurities or contaminants. Then, they undergo a surface treatment to enhance adhesion and corrosion resistance. Next, a primer or base coat is applied to provide a smooth surface and improve the overall coating performance. After that, a topcoat is applied to add color, aesthetics, and additional protection. The coated aluminum coils are then cured or dried to ensure proper bonding and durability. Finally, the coated coils are inspected for quality assurance before being shipped for use in different applications such as construction, automotive, or packaging industries.

What is the role of stretch bending in shaping aluminum coils?

Stretch bending is a crucial technique in shaping aluminum coils as it helps to achieve the desired curvature and shape. By stretching the aluminum coil, it becomes more malleable and easier to bend into various forms and angles. This process allows for the creation of precise and complex shapes while maintaining the structural integrity and strength of the material.

Wholesale Aluminum Coils from supplier in Cyprus

Our team of experts is dedicated to providing excellent customer service and ensuring timely delivery of your Aluminum Coils orders. We understand the importance of quality and reliability in the construction industry, which is why we only source products from trusted manufacturers. Whether you need Aluminum Coils for roofing, cladding, or other applications, we have the right solutions for you.

In addition to sales and quotations, we also offer technical support to assist you in choosing the right Aluminum Coils products for your project. Our knowledgeable staff can provide guidance on product specifications, applications, and installation methods. We aim to be your reliable partner throughout the entire procurement process, from initial inquiry to after-sales support.

As part of the CNBM group, we have access to a vast network of resources and expertise. This allows us to negotiate competitive prices and offer cost-effective solutions for your Aluminum Coils needs. Our strong relationships with suppliers ensure that we can meet your requirements in terms of quality, quantity, and budget.

We take pride in our commitment to customer satisfaction and strive to exceed your expectations. Whether you are a contractor, builder, or distributor in Cyprus, we are here to fulfill your Aluminum Coils requirements. Contact us today for more information and let us be your trusted supplier of Aluminum Coils in Cyprus.

In addition to sales and quotations, we also offer technical support to assist you in choosing the right Aluminum Coils products for your project. Our knowledgeable staff can provide guidance on product specifications, applications, and installation methods. We aim to be your reliable partner throughout the entire procurement process, from initial inquiry to after-sales support.

As part of the CNBM group, we have access to a vast network of resources and expertise. This allows us to negotiate competitive prices and offer cost-effective solutions for your Aluminum Coils needs. Our strong relationships with suppliers ensure that we can meet your requirements in terms of quality, quantity, and budget.

We take pride in our commitment to customer satisfaction and strive to exceed your expectations. Whether you are a contractor, builder, or distributor in Cyprus, we are here to fulfill your Aluminum Coils requirements. Contact us today for more information and let us be your trusted supplier of Aluminum Coils in Cyprus.