All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are taken to enhance the corrosion resistance of aluminum profiles in challenging marine environments?

Several measures are taken to enhance the corrosion resistance of aluminum profiles in challenging marine environments. The profiles are typically coated with specialized anti-corrosion materials, such as anodizing or powder coating, which provide an additional protective layer. Additionally, the profiles may undergo pre-treatment processes like chemical cleaning or etching to remove any contaminants and promote adhesion of the coating. Design modifications can also be implemented, such as incorporating drainage systems to prevent water accumulation and using corrosion-resistant alloys. Regular maintenance and inspections are crucial to identify and address any potential corrosion issues promptly.

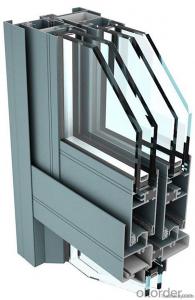

How are aluminum profiles used in the design and construction of energy-efficient water distribution and treatment facilities?

Aluminum profiles are commonly used in the design and construction of energy-efficient water distribution and treatment facilities due to their numerous benefits. These profiles are lightweight, corrosion-resistant, and have high strength-to-weight ratio, making them ideal for various structural components such as pipes, conduits, and frames. By using aluminum profiles, these facilities can achieve energy-efficiency as they minimize material waste, reduce transportation costs, and can be easily recycled. Additionally, aluminum profiles can be easily customized and integrated with insulation materials, helping to improve the overall energy performance of water distribution and treatment facilities.

How are aluminum profiles employed in the production of automotive components?

Aluminum profiles are extensively used in the production of automotive components due to their lightweight and durable nature. These profiles are employed in various applications such as frame structures, body panels, engine components, and chassis parts. Their high strength-to-weight ratio and corrosion resistance make them ideal for enhancing fuel efficiency, improving vehicle performance, and reducing overall weight. Aluminum profiles also aid in achieving design flexibility, enabling manufacturers to create intricate and aerodynamic automotive components.

Wholesale Aluminum Profiles from supplier in Italy

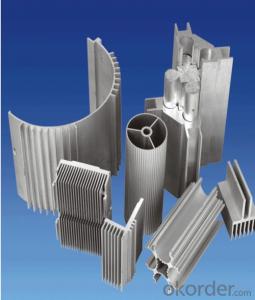

With our Aluminum Profiles, you can expect high-quality materials that are durable and reliable. We have a wide range of profiles available, including standard profiles, custom profiles, and special profiles for specific applications. Our profiles are made using advanced manufacturing processes, ensuring precision and consistency in every piece.

In addition to supplying Aluminum Profiles, we also offer value-added services such as cutting, machining, surface treatment, and assembly. Our team of skilled technicians and engineers are well-equipped to handle any customization or modification requests to meet your specific project requirements.

As a subsidiary of CNBM, we have access to a vast network of resources and supply chains, allowing us to provide competitive pricing and efficient delivery. We understand the importance of timely delivery and can ensure that your Aluminum Profiles will reach you on time, every time.

Furthermore, our years of experience in the Italian market have given us valuable insights and knowledge about local regulations, standards, and preferences. We can provide guidance and advice to help you make informed decisions and optimize your projects.

Whether you are in the construction, automotive, aerospace, or any other industry, our Aluminum Profiles can be tailored to suit your needs. We strive to provide excellent customer service and are committed to exceeding your expectations.

Contact us today to discuss your Aluminum Profiles requirements in Italy. We are confident that our products and services will meet your needs and contribute to the success of your projects.

In addition to supplying Aluminum Profiles, we also offer value-added services such as cutting, machining, surface treatment, and assembly. Our team of skilled technicians and engineers are well-equipped to handle any customization or modification requests to meet your specific project requirements.

As a subsidiary of CNBM, we have access to a vast network of resources and supply chains, allowing us to provide competitive pricing and efficient delivery. We understand the importance of timely delivery and can ensure that your Aluminum Profiles will reach you on time, every time.

Furthermore, our years of experience in the Italian market have given us valuable insights and knowledge about local regulations, standards, and preferences. We can provide guidance and advice to help you make informed decisions and optimize your projects.

Whether you are in the construction, automotive, aerospace, or any other industry, our Aluminum Profiles can be tailored to suit your needs. We strive to provide excellent customer service and are committed to exceeding your expectations.

Contact us today to discuss your Aluminum Profiles requirements in Italy. We are confident that our products and services will meet your needs and contribute to the success of your projects.