All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

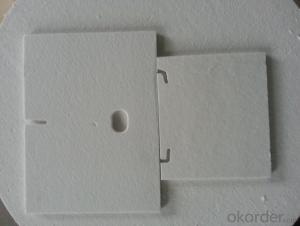

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials perform in boilers for power generation?

Refractory materials perform crucial roles in boilers for power generation by providing insulation and protection against high temperatures and chemical corrosion. They help maintain the structural integrity of the boilers, prevent heat loss, and promote efficient combustion processes. Additionally, refractory materials enable the boilers to withstand thermal cycling, mechanical stress, and harsh operating conditions, thereby enhancing their longevity and reliability.

How do refractory materials contribute to the prevention of air pollution?

Refractory materials contribute to the prevention of air pollution by being able to withstand high temperatures and harsh chemical environments, allowing them to be used in various industrial processes such as incineration and combustion. These materials help contain and control the release of harmful pollutants, such as emissions from fuel combustion, by providing a barrier that prevents them from escaping into the atmosphere. Additionally, refractory materials can be designed to have low permeability, minimizing the leakage of pollutants through their structure.

How are refractory coatings used in thermal insulation?

Refractory coatings are applied to surfaces to enhance thermal insulation by reducing heat transfer and increasing the material's resistance to high temperatures. These coatings create a protective barrier that reflects or absorbs heat, preventing it from escaping or entering the insulated area. This improves energy efficiency, reduces heat loss, and provides a more comfortable environment.

Wholesale Refractory Materials from supplier in Ireland

Contact us today to discuss your Refractory Materials requirements and discover how we can add value to your business.

Hot Search

- Monolithic Refractories in Czech Republic

- Ceramic Fiber Products in Luxembourg

- Refractory Bricks in Malawi

- Raw Materials For Refractory in Uganda

- Ceramic Fiber Products in Lithuania

- Refractory Bricks in Slovenia

- Raw Materials For Refractory in Panama

- Monolithic Refractories in Greece

- Monolithic Refractories in Colombia

- Raw Materials For Refractory in Jamaica