All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do you calculate the energy efficiency and environmental impact of projects involving aluminum profiles in various industries?

To calculate the energy efficiency and environmental impact of projects involving aluminum profiles in various industries, several factors need to be considered.

Firstly, the energy efficiency of aluminum profiles can be determined by analyzing the energy consumption during the production process. This involves assessing the amount of energy required for mining bauxite (the primary source of aluminum), refining it into alumina, and subsequently smelting it into aluminum. Additionally, the energy utilized during the extrusion, fabrication, and finishing processes of the aluminum profiles should also be accounted for.

Secondly, the environmental impact can be evaluated by considering the emissions associated with aluminum production. This includes greenhouse gas emissions such as carbon dioxide, as well as other pollutants released during the extraction and refining processes. Assessing the waste generated from these processes and its disposal methods is also crucial.

Furthermore, the use phase of aluminum profiles should be considered to understand their overall environmental impact. This involves analyzing the energy consumption and potential emissions associated with the manufacturing, installation, and maintenance of products utilizing aluminum profiles, as well as their end-of-life management.

To calculate the energy efficiency and environmental impact comprehensively, life cycle assessment (LCA) methodologies can be employed. LCA considers the entire life cycle of a product, from raw material extraction to disposal, including all processes and energy inputs involved. It provides a holistic view of the energy efficiency and environmental impact, allowing for informed decision-making and the identification of potential areas for improvement in projects involving aluminum profiles across various industries.

How are aluminum profiles employed in the design of efficient and sustainable public transportation systems?

Aluminum profiles are commonly used in the design of efficient and sustainable public transportation systems due to their lightweight and durable nature. These profiles are utilized in the construction of various components such as frames, panels, and doors, which help reduce the overall weight of the vehicles and improve fuel efficiency. Additionally, aluminum profiles offer excellent resistance to corrosion, making them suitable for outdoor applications and increasing the lifespan of the transportation systems. This lightweight and sustainable material also aids in reducing the carbon footprint of public transportation, contributing to a greener and more environmentally friendly mode of transportation.

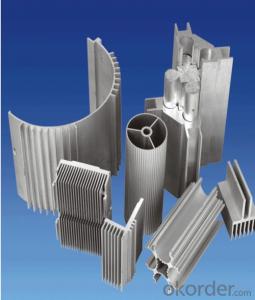

Can you explain the extrusion process in the production of aluminum profiles?

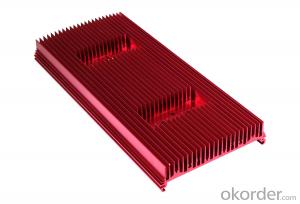

The extrusion process in the production of aluminum profiles involves forcing a heated aluminum billet through a shaped die to create a desired shape. This process allows for the production of complex, continuous profiles with consistent dimensions and high precision. The extruded aluminum profiles can be used in various industries such as construction, automotive, and aerospace, offering lightweight yet strong solutions for a wide range of applications.

Wholesale Aluminum Profiles from supplier in Peru

With our commitment to quality and customer satisfaction, we strive to deliver the best Aluminum Profiles products that meet international standards. We work closely with clients to understand their specific needs and provide customized solutions that align with their requirements. Our team of experts is well-equipped with technical knowledge and can assist you in selecting the right Aluminum Profiles for your projects.

In addition to our product offerings, we also provide sales, quotation, and technical support services to ensure a seamless experience for our customers. Our dedicated sales team is always ready to assist you with any inquiries or requests, providing prompt and reliable service. We also offer competitive pricing and flexible payment options to suit your budget and convenience.

Furthermore, as a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, enabling us to offer comprehensive procurement solutions for Aluminum Profiles in Peru. We can handle all aspects of the procurement process, from sourcing and negotiation to logistics and delivery, ensuring a hassle-free experience for our customers.

With our extensive market experience in Peru, we have developed a deep understanding of the local industry trends and customer preferences. We can provide invaluable insights and expertise to help you make informed decisions and optimize the success of your projects. Whether you are in the construction, manufacturing, or any other industry that requires Aluminum Profiles, we are confident in our ability to meet your needs and exceed your expectations.

Choose us as your trusted supplier of Aluminum Profiles in Peru and experience the difference of working with a renowned company that is committed to quality, customer satisfaction, and delivering exceptional value. Contact us today to discuss your requirements and let us assist you in achieving your project goals.

In addition to our product offerings, we also provide sales, quotation, and technical support services to ensure a seamless experience for our customers. Our dedicated sales team is always ready to assist you with any inquiries or requests, providing prompt and reliable service. We also offer competitive pricing and flexible payment options to suit your budget and convenience.

Furthermore, as a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of suppliers and resources, enabling us to offer comprehensive procurement solutions for Aluminum Profiles in Peru. We can handle all aspects of the procurement process, from sourcing and negotiation to logistics and delivery, ensuring a hassle-free experience for our customers.

With our extensive market experience in Peru, we have developed a deep understanding of the local industry trends and customer preferences. We can provide invaluable insights and expertise to help you make informed decisions and optimize the success of your projects. Whether you are in the construction, manufacturing, or any other industry that requires Aluminum Profiles, we are confident in our ability to meet your needs and exceed your expectations.

Choose us as your trusted supplier of Aluminum Profiles in Peru and experience the difference of working with a renowned company that is committed to quality, customer satisfaction, and delivering exceptional value. Contact us today to discuss your requirements and let us assist you in achieving your project goals.