All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

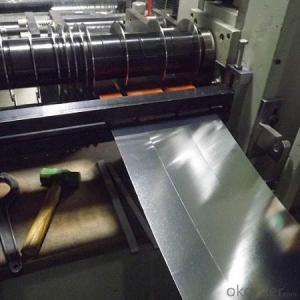

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How is tinplate different from regular steel?

Tinplate is different from regular steel in that it is coated with a thin layer of tin, which provides protection against corrosion and enhances its aesthetic appeal. This coating also makes tinplate more suitable for food packaging as it prevents interaction between the metal and the food. Regular steel, on the other hand, does not have this tin coating and is more commonly used in construction and industrial applications.

What are the sustainability initiatives in the tinplate manufacturing industry to promote eco-friendly packaging and materials?

The tinplate manufacturing industry has implemented several sustainability initiatives to promote eco-friendly packaging and materials. These include the use of recyclable tinplate, which can be easily recovered and reused, reducing waste and minimizing environmental impact. Additionally, manufacturers are focusing on optimizing production processes to reduce energy consumption and greenhouse gas emissions. They are also collaborating with stakeholders to promote sustainable sourcing of raw materials and implementing responsible waste management practices. By adopting these initiatives, the tinplate manufacturing industry aims to contribute to a more sustainable and eco-friendly packaging and materials ecosystem.

What industries have witnessed the most significant growth in tinplate usage?

The packaging industry, specifically the food and beverage sector, has witnessed the most significant growth in tinplate usage. Tinplate cans are widely used for preserving and packaging various food and drink products due to their durability, versatility, and ability to maintain product freshness. Additionally, the automotive industry has also experienced significant growth in tinplate usage, particularly for manufacturing automotive parts and components due to their excellent corrosion resistance and formability properties.

How is tinplate used in the construction industry?

Tinplate is used in the construction industry for various applications such as roofing, cladding, and ductwork. It provides a durable and corrosion-resistant coating, making it suitable for exterior use. Tinplate roofing sheets are commonly used in commercial and residential buildings due to their weather resistance and long lifespan. Additionally, tinplate is often used in the construction of air conditioning ducts, as it helps prevent rust and improves the overall durability of the system.

Wholesale Tinplate from supplier in Peru

With our sales team, customers can expect prompt and efficient service, ensuring a smooth purchasing process. We offer competitive quotations based on market trends and customer requirements, ensuring cost-effective solutions for your Tinplate needs.

Moreover, our technical support team is always ready to assist you with any inquiries or challenges you may encounter during your projects. We have a deep understanding of the technical specifications and applications of Tinplate, allowing us to provide expert advice and recommendations.

Being a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and suppliers. This enables us to offer a diverse range of Tinplate products, meeting various industry requirements and specifications.

We understand the unique demands of the Peruvian market and are well-versed in local regulations and standards. Our years of experience in Peru have provided us with valuable insights into the industry, allowing us to anticipate market trends and offer tailored solutions to our customers.

In summary, our company is committed to delivering a seamless Tinplate procurement experience in Peru. With our comprehensive services, extensive product range, and market expertise, we aim to be your trusted partner for all your Tinplate needs.

Moreover, our technical support team is always ready to assist you with any inquiries or challenges you may encounter during your projects. We have a deep understanding of the technical specifications and applications of Tinplate, allowing us to provide expert advice and recommendations.

Being a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and suppliers. This enables us to offer a diverse range of Tinplate products, meeting various industry requirements and specifications.

We understand the unique demands of the Peruvian market and are well-versed in local regulations and standards. Our years of experience in Peru have provided us with valuable insights into the industry, allowing us to anticipate market trends and offer tailored solutions to our customers.

In summary, our company is committed to delivering a seamless Tinplate procurement experience in Peru. With our comprehensive services, extensive product range, and market expertise, we aim to be your trusted partner for all your Tinplate needs.