All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

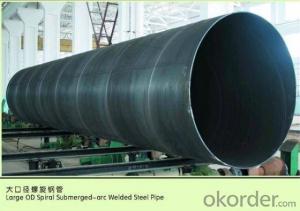

Can welded steel pipes be used for automotive testing facilities?

Yes, welded steel pipes can be used for automotive testing facilities. Welded steel pipes are commonly used in various industrial applications, including automotive testing facilities, due to their strength, durability, and ability to withstand high pressure and temperature conditions. These pipes can be used for conveying fluids, gases, or as structural components for different testing equipment and systems in automotive facilities.

What are the different methods used for cutting welded steel pipe?

There are several methods used for cutting welded steel pipe, including manual cutting with a hacksaw or reciprocating saw, flame cutting with oxy-fuel torches, plasma cutting, and using mechanical cutting tools such as pipe cutters or band saws. Each method has its own advantages and limitations, depending on factors such as the thickness of the pipe, required precision, and available equipment.

What are the considerations for welding techniques when working with welded steel pipes?

When working with welded steel pipes, there are several considerations for welding techniques that should be taken into account. Firstly, the type of welding process used is important, as different techniques, such as shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), or gas metal arc welding (GMAW), may be suitable depending on the specific requirements of the project.

The thickness and diameter of the steel pipes also play a crucial role in determining the welding technique. Thicker pipes may require preheating to avoid excessive heat input, while thinner pipes may need careful control of the welding parameters to prevent burn-through.

Additionally, the position of the weld joint, whether it is horizontal, vertical, or overhead, can impact the choice of welding technique and the skill level required from the welder. Proper joint preparation, including cleaning, beveling, and alignment, is necessary to ensure sound welds and minimize defects.

Considerations should also be given to the filler material used, as it should have suitable mechanical properties and composition to match the base metal and meet the required specifications. The selection of shielding gas or flux is important for protecting the weld pool from contaminants and ensuring good fusion.

Lastly, safety precautions, such as wearing appropriate personal protective equipment (PPE) and ensuring proper ventilation, should always be followed to protect the welder from hazards associated with welding, such as fumes, sparks, and UV radiation.

Overall, considering factors such as the type of welding process, pipe thickness and diameter, joint position, filler material, and safety measures are all crucial when determining the welding techniques for working with welded steel pipes.

How are welded steel pipes tested for quality and durability?

Welded steel pipes are tested for quality and durability through various methods. Non-destructive testing techniques such as ultrasonic testing, radiography, and magnetic particle inspection are commonly used to detect any defects or imperfections in the welds. Additionally, destructive testing methods like tensile testing and impact testing are performed to assess the mechanical properties of the pipes, ensuring they meet the required standards. These rigorous testing procedures ensure that welded steel pipes are of high quality and possess the necessary durability for their intended applications.

What is the impact of heat treatment on the mechanical properties of welded steel pipe?

Heat treatment can have a significant impact on the mechanical properties of welded steel pipe. By subjecting the pipe to controlled heating and cooling processes, the material's microstructure is altered, leading to changes in its strength, hardness, and toughness. Heat treatment can help reduce residual stresses, improve the pipe's ductility, and increase its resistance to cracking and deformation. It can also refine the grain structure, resulting in a more uniform and homogeneous material. However, improper heat treatment can also lead to negative effects, such as increased brittleness or reduced corrosion resistance. Therefore, careful consideration of the desired mechanical properties and appropriate heat treatment parameters are crucial to optimizing the performance of welded steel pipes.

Wholesale Welded Steel Pipe from supplier in Peru

With our strong reputation, comprehensive range of products and services, and the backing of CNBM, a Fortune Global 500 company, we are confident in providing you with a convenient and reliable solution for all your Welded Steel Pipe procurement needs in Peru.

Our team is dedicated to providing excellent customer service, ensuring that you receive the support you need throughout the entire process. From sales and quotations to technical guidance, we are here to assist you every step of the way.

We understand that every project is unique and may have specific requirements. That is why we offer a diverse selection of Welded Steel Pipe options, allowing you to find the right products to suit your needs. Our extensive product portfolio is backed by our market experience in Peru, ensuring that we can provide valuable insights and guidance for your projects.

When you choose us as your Welded Steel Pipe supplier in Peru, you can trust in the reliability and quality of our products. We are committed to delivering products that meet industry standards and exceed customer expectations. Additionally, our efficient project support will help ensure a seamless and successful experience.

Whether you are working on construction projects, industrial applications, or any other purpose, we have the expertise and resources to meet your unique requirements. Choose us as your trusted partner in Peru for all your Welded Steel Pipe needs.

Our team is dedicated to providing excellent customer service, ensuring that you receive the support you need throughout the entire process. From sales and quotations to technical guidance, we are here to assist you every step of the way.

We understand that every project is unique and may have specific requirements. That is why we offer a diverse selection of Welded Steel Pipe options, allowing you to find the right products to suit your needs. Our extensive product portfolio is backed by our market experience in Peru, ensuring that we can provide valuable insights and guidance for your projects.

When you choose us as your Welded Steel Pipe supplier in Peru, you can trust in the reliability and quality of our products. We are committed to delivering products that meet industry standards and exceed customer expectations. Additionally, our efficient project support will help ensure a seamless and successful experience.

Whether you are working on construction projects, industrial applications, or any other purpose, we have the expertise and resources to meet your unique requirements. Choose us as your trusted partner in Peru for all your Welded Steel Pipe needs.