Aluminium Anodizing for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Structure of Aluminium Anodizing for Construction Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Anodizing for Construction Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

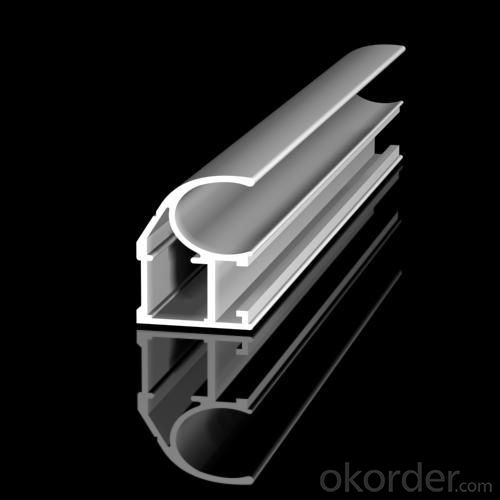

Images of the Aluminium Anodizing for Construction Application:

Aluminium Anodizing for Construction Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q:Aluminum profile connecting piece

- Very little to buy this alone, and only with industrial aluminum suppliers. - selling on Taobao is also a way if the price is appropriate.

- Q:Can aluminum profiles be used in aerospace applications?

- Yes, aluminum profiles can be used in aerospace applications. Aluminum has been widely used in the aerospace industry for many years due to its various advantageous properties. Aluminum profiles are lightweight, which is crucial in aerospace applications as it helps reduce the overall weight of the aircraft, resulting in improved fuel efficiency and increased payload capacity. Additionally, aluminum profiles possess high strength-to-weight ratio, making them strong enough to withstand the stress and forces experienced during flight. Aluminum is also corrosion-resistant, which is beneficial in the harsh and corrosive environment of aerospace. Furthermore, aluminum profiles can be easily machined and formed into complex shapes, allowing for greater design flexibility. Overall, the combination of lightweight, strength, corrosion resistance, and ease of fabrication makes aluminum profiles an excellent choice for various aerospace applications such as aircraft frames, wings, fuselages, and structural components.

- Q:How can I control the hardness of 6063 aluminum profile at 6-9 degrees?

- Two 、 soft burning treatment:2.1 purpose:Materials for stretching and stretching include rolling materials, extrusion materials and forging materials:Casting - Hot Processing - cold processing - finished materialIn the process of hot or cold processing processing, material processing hardening, the strength increases or lead to work hardening, the strength increases or lead to reduced processing. In order to eliminate the work hardening, for cold working before or after the application of heat treatment is soft burning treatment. Its purpose is to make use of the material is needed.2.2 classification:Due to the different conditions of soft burning:2.2.1 part of soft burning: only part of the work hardening is eliminated, the treatment temperature is below the recrystallization temperature, the actual temperature depends on the strength, and the higher the strength, the lower the treatment temperature2.2.2 completely soft burning: treatment temperature in the recrystallization temperature or slightly higher, so that the material recrystallization, and completely eliminate the work hardening, also make the strength to the lowest stateThere is time and soft burning:2.2.3 soft burning before cold or cold start process, soft burning treatment added, usually completely soft burning, its purpose in the recovery process, and make the next function more smoothly, and the control of the organization, in order to fit for the final product requirements.2.2.4 ultimate soft burning: the main purpose is to adjust the final strength level of the finished product, that is, to adjust the chain3 processing common sense

- Q:What are the different powder coating options for aluminum profiles?

- There are several powder coating options available for aluminum profiles, including polyester, epoxy, polyurethane, and hybrid powder coatings. Each option offers unique characteristics and benefits, such as durability, corrosion resistance, color retention, and weather resistance. The choice of powder coating depends on the specific requirements and intended use of the aluminum profiles.

- Q:How do aluminum profiles compare to other types of materials?

- Aluminum profiles have several advantages compared to other types of materials. Firstly, aluminum is known for its lightweight nature, making it easier to handle and transport. This characteristic is particularly beneficial in industries where weight reduction is crucial, such as aerospace and automotive sectors. Secondly, aluminum profiles offer excellent corrosion resistance. Unlike materials like steel or iron, aluminum does not rust when exposed to moisture or other corrosive elements. This makes aluminum profiles ideal for outdoor applications or in environments where moisture is present, such as marine or coastal areas. Moreover, aluminum profiles have high strength-to-weight ratio, meaning they are relatively strong while being lightweight. This property enables the use of aluminum in various structural applications, where strength is important but weight reduction is also desired. Additionally, aluminum profiles are highly versatile and can be easily extruded into different shapes and sizes to meet specific design requirements. This flexibility allows for customization and adaptability in various industries, including construction, transportation, and industrial manufacturing. Lastly, aluminum is a highly sustainable material. It is 100% recyclable, meaning it can be melted down and reused without any loss in quality. This contributes to reducing environmental impact and promotes a circular economy. Overall, aluminum profiles offer a combination of lightweight, corrosion resistance, strength, versatility, and sustainability, making them a favorable choice over other types of materials in many applications.

- Q:What industries commonly use aluminum profiles?

- Aluminum profiles are widely used in various industries due to their unique properties and versatility. One of the most common industries that utilize aluminum profiles is the construction industry. Aluminum profiles are used in the construction of windows, doors, curtain walls, and other architectural applications. The lightweight nature of aluminum makes it an ideal choice for these applications, as it reduces the load on the building structure. The automotive industry also extensively uses aluminum profiles. They are used in the manufacturing of car frames, body panels, and components, as they offer excellent strength-to-weight ratio and corrosion resistance. Aluminum profiles help in reducing the overall weight of vehicles, leading to improved fuel efficiency and performance. The aerospace industry heavily relies on aluminum profiles for aircraft manufacturing. Aluminum profiles are used in the construction of aircraft frames, wings, and fuselages. Their high strength and durability make them suitable for withstanding the rigors of flight, while their lightweight nature contributes to fuel efficiency. The electronics industry also commonly uses aluminum profiles. They are used in the manufacturing of heat sinks, which help dissipate heat from electronic components. Aluminum's excellent thermal conductivity ensures effective heat transfer, preventing damage to sensitive electronic devices. Furthermore, the furniture industry utilizes aluminum profiles in the production of lightweight and durable furniture pieces. Aluminum profiles are used in the construction of frames for chairs, tables, shelves, and various other furniture items. Their corrosion resistance and aesthetic appeal make them a popular choice for both indoor and outdoor furniture. In summary, industries such as construction, automotive, aerospace, electronics, and furniture commonly use aluminum profiles due to their lightweight, strength, corrosion resistance, and versatility. These profiles play a crucial role in enhancing the performance, efficiency, and durability of products in these industries.

- Q:How to sell aluminum profile and accessories, how to find customers online?

- Is a wholesale market or two market wholesale it?AskDirectly imported from Germany Suzhou SUNDT Automation System Co. Ltd is the sole agentChasing the answerYou can first publish some company information in China profile network, China building materials network, China hardware business network, Alibaba wholesale network. Your local website will also be released, and more information will be found on Baidu search. If you intend to do electricity supplier promotion is essential.I am wholesale doors and windows accessories, mainly for customers to do aluminum alloy steel processing, they do not how to access the Internet, so I posted on the Internet information is not very effective. Mainly rely on door-to-door sales.If you are the general agent, you can find the head office to get some links pictures ah, these hair on the internet. The head office is sure to help the dealer!

- Q:Are there any specific maintenance requirements for aluminum profiles?

- Maintenance requirements for aluminum profiles are necessary to ensure their longevity and performance. To begin with, it is crucial to regularly clean the profiles to eliminate any dirt, dust, or contaminants that may have settled on the surface. This can be achieved by using a mild detergent or soap mixed with water and a soft cloth or sponge. It is important to avoid using harsh or abrasive cleaners as they can harm the protective coating on the aluminum. In addition, periodic inspections should be conducted to identify any signs of damage or wear on the aluminum profiles. This involves checking for dents, scratches, or corrosion. If any damage is detected, immediate attention should be given to prevent further deterioration. Moreover, lubrication may be necessary for specific moving parts or joints in the aluminum profiles. The manufacturer's recommendations should be followed, and a suitable lubricant or silicone spray can be used. Furthermore, it is crucial to inspect and maintain the protective coating on the aluminum profiles. Over time, this coating may wear off, which exposes the aluminum to potential corrosion. In such situations, applying a new coating or protective sealant is advisable to maintain the durability and appearance of the profiles. Lastly, it is essential to adhere to any specific maintenance guidelines provided by the manufacturer. These guidelines may include specific instructions or recommendations for cleaning, maintenance, and repair. Following these guidelines will ensure that the profiles remain in good condition and retain their functionality and aesthetic appeal for an extended period of time.

- Q:What are the advantages of using aluminum profiles in the oil and gas industry?

- There are several advantages of using aluminum profiles in the oil and gas industry. Firstly, aluminum profiles are lightweight yet highly durable, making them ideal for applications that require strength and resistance to harsh environments. Secondly, aluminum profiles have excellent corrosion resistance properties, ensuring their longevity even in corrosive environments found in the oil and gas industry. Additionally, aluminum profiles offer excellent thermal conductivity, allowing for efficient heat transfer and management in various oil and gas processes. Furthermore, aluminum profiles are easy to fabricate and assemble, enabling quick and cost-effective installation. Lastly, aluminum is a recyclable material, aligning with sustainability goals and reducing environmental impact in the oil and gas industry.

- Q:How much is aluminum section ton?

- According to the manufacturer's management costs are not the same as the surface treatment method, the price in the aluminum ingot futures basis price plus 3000-13000 yuan processing fee

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Anodizing for Construction Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords