Aluminum Profiles AA3xxx

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Profiles AA3xxx

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

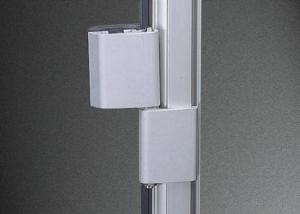

2 Usage/Applications of Aluminum Profiles AA3xxx

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles AA3xxx

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles AA3xxx

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q:Can aluminum profiles be used in green building projects?

- Yes, aluminum profiles can be used in green building projects. Aluminum is a highly sustainable material that has several advantages when it comes to green building. Firstly, aluminum is lightweight, which reduces transportation costs and energy consumption during construction. Additionally, aluminum is 100% recyclable, meaning that it can be reused indefinitely without any degradation in quality. This makes it an excellent choice for green building projects as it contributes to the reduction of waste and promotes a circular economy. Moreover, aluminum has a long lifespan and requires minimal maintenance, which further contributes to its sustainability. It is also worth mentioning that aluminum profiles can be easily integrated with other green building materials such as glass, allowing for energy-efficient designs that maximize natural light and minimize the need for artificial lighting. Overall, aluminum profiles are a sustainable and versatile choice for green building projects.

- Q:Can aluminum profiles be used in agricultural greenhouse manufacturing?

- Yes, aluminum profiles can be used in agricultural greenhouse manufacturing. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for use in greenhouse structures. Aluminum profiles can be used to create the framework of the greenhouse, providing structural support and stability. Additionally, aluminum profiles can be easily customized and assembled, allowing for flexibility in greenhouse design. The use of aluminum profiles in agricultural greenhouse manufacturing helps to ensure a long-lasting and efficient structure for growing plants.

- Q:How can the aluminum profile T6 and T5 be distinguished?

- Hardness is generally measured by a Brinell hardness tester. T5 is subjected to high temperature molding and air cooling quenching in the shortest possible time. The T6 is treated with solid solution after artificial aging. So there is a difference between the two. But from the appearance of it is difficult to judge, experienced hands can be used to swing aluminum, roughly judged

- Q:How do I choose the right aluminum profile for my project?

- When choosing the right aluminum profile for your project, consider factors such as the desired strength and durability, the specific dimensions and shape required, the intended application or purpose, and any particular aesthetic or design preferences. It is also important to evaluate the compatibility of the chosen profile with other components or materials that will be used in your project. Research and consultation with experts or suppliers can provide valuable insights and guidance in making an informed decision.

- Q:How to sell and sell industrial aluminium profiles?

- For the industrial aluminum profile enterprise, this is the most valuable customer resource, and also is the high-quality customer we usually call. Of course, the quality of customer mining, the most important thing is to discuss and communicate with customers. We must start from the position of customers, understand their requirements for products, know what they want to achieve the desired, can use their brains, for them to benefit by mutual discussion, analysis and reflection, so customers are thinking, anxious customers, so in fact, let customers choose our is the logical thing. It should be said that this is the most critical moment in the whole sale, so don't let yourself lose here.

- Q:Can aluminum profiles be used in lightweight construction applications?

- Aluminum profiles are definitely applicable in lightweight construction. They possess a lightweight and versatile nature that brings numerous advantages to construction projects. With a high strength-to-weight ratio, structures can be built with less material yet still maintain strength and durability. This makes aluminum profiles an ideal choice for lightweight construction where weight reduction is crucial. Various construction projects, including building facades, interior partitions, roofing systems, and structural frameworks, commonly utilize aluminum profiles. They are particularly favored in industries such as aerospace, automotive, and marine where reducing weight is of utmost importance. Additionally, aluminum profiles exhibit excellent resistance to corrosion, making them suitable for outdoor and high-moisture environments. Their high malleability allows for easy fabrication into different shapes and sizes, enabling customized designs and simple installation. Moreover, aluminum is an eco-friendly material as it can be recycled infinitely without compromising its properties. To sum up, the widespread use of aluminum profiles in lightweight construction stems from their lightweight nature, strength, durability, corrosion resistance, malleability, and environmental benefits.

- Q:Can aluminum profiles be used for electrical applications?

- Yes, aluminum profiles can be used for electrical applications. Aluminum is a highly conductive material, making it suitable for electrical conductivity. Aluminum profiles are commonly used in electrical applications such as power distribution systems, wiring conduits, and bus bars. They provide a lightweight and cost-effective solution for electrical installations. Additionally, aluminum profiles offer good thermal conductivity, which helps in dissipating heat generated by electrical components. However, it is important to consider the specific requirements of the electrical application and ensure that the aluminum profiles meet the necessary electrical safety standards and regulations.

- Q:Regarding the wall thickness of aluminum alloy profiles, are there any standards in the country?

- < technical specification for glass curtain wall JGJ102-2003> open section bar is not less than 3.0mm. For example, the beams are mostly open and closed at one end with a cover plate. Closed profiles such as stand up, mostly closed type, not less than 2.5mm, these are only the minimum requirements for wall thickness, but also in accordance with the calculation of the book in the calculation of the wall thickness.

- Q:How do you ensure proper electrical grounding with aluminum profiles?

- In order to achieve proper electrical grounding with aluminum profiles, it is necessary to follow a few essential steps. To begin with, it is crucial to ensure the cleanliness and freedom from dirt, dust, or oxidation of all aluminum profiles. This can be accomplished by utilizing an appropriate cleaning agent or solvent to eliminate any contaminants that may impede the grounding process. Subsequently, the utilization of conductive hardware, such as grounding clips or brackets specifically designed for aluminum profiles, can enable the attainment of proper electrical grounding. These hardware components must be securely affixed to the aluminum profiles to establish a dependable electrical connection. Moreover, establishing a robust electrical connection between the aluminum profiles and the grounding system is of utmost importance. This can be accomplished by employing copper or aluminum grounding conductors that are appropriately sized and firmly connected to both the aluminum profiles and the grounding system. Additionally, it is essential to conduct regular inspections of the grounding system to ensure its effectiveness. This may involve scrutinizing for any loose connections, indications of corrosion, or damage to the grounding conductors. Any identified issues should be promptly addressed and repaired to maintain proper electrical grounding. Lastly, it is advisable to consult with a qualified electrician or engineer who specializes in electrical grounding when dealing with aluminum profiles. They can offer specific guidance and guarantee compliance with pertinent electrical codes and standards to ensure the proper and safe grounding of the system.

- Q:Are aluminum profiles suitable for modular office systems?

- Yes, aluminum profiles are suitable for modular office systems. Aluminum profiles are lightweight, durable, and have excellent structural integrity, making them ideal for constructing modular office systems. They are easy to assemble, disassemble, and reconfigure, allowing for flexibility and adaptability in office layouts. Additionally, aluminum profiles can be customized to meet specific design requirements, offering a sleek and modern aesthetic to modular office systems.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Profiles AA3xxx

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords