All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the measures to protect aluminum profiles against corrosion in harsh industrial environments?

There are several measures that can be taken to protect aluminum profiles against corrosion in harsh industrial environments.

Firstly, applying a protective coating such as anodizing or powder coating can create a barrier between the aluminum surface and the corrosive elements. Anodizing involves immersing the aluminum in an electrolyte bath and passing an electric current through it to form a durable oxide layer. Powder coating involves applying a dry powder to the aluminum surface and then heating it to form a protective coating.

Secondly, using corrosion-resistant alloys or adding alloying elements to the aluminum can enhance its resistance to corrosion. Alloys such as aluminum-magnesium or aluminum-zinc can provide better protection in harsh environments.

Thirdly, proper maintenance and regular cleaning of the aluminum profiles are essential. This includes removing any accumulated dirt, debris, or corrosive substances that may promote corrosion.

Lastly, implementing preventive measures such as installing protective covers, using corrosion inhibitors or applying sealants can further enhance the durability and longevity of aluminum profiles in harsh industrial environments.

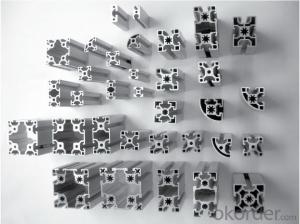

What are the available shapes and sizes for aluminum profiles, and how are they determined?

There is a wide range of shapes and sizes available for aluminum profiles, including rectangular, square, round, T-shaped, I-shaped, and custom profiles. The determination of these shapes and sizes is usually based on the specific application requirements, structural considerations, and design aesthetics. Manufacturers often offer standard profiles with predetermined dimensions, while custom profiles can be created to meet unique specifications. The selection process involves analyzing factors such as load-bearing capacity, functionality, aesthetics, and cost-effectiveness to determine the most suitable shape and size for the intended application.

What is the role of aluminum profiles in the construction of modular structures?

Aluminum profiles play a crucial role in the construction of modular structures as they provide strength, durability, and versatility. These profiles are used for framing, support structures, and connections, allowing for easy assembly and disassembly of modular components. They are lightweight yet sturdy, making them ideal for constructing modular buildings, such as temporary shelters, portable offices, and even off-site housing. Additionally, aluminum profiles offer excellent corrosion resistance, which ensures the longevity of the modular structures in various environments.

Wholesale Aluminum Profiles from supplier in Armenia

Whether you are in need of standard or customized aluminum profiles, we have a wide selection to meet your specific requirements. Our team of experienced professionals is dedicated to providing excellent customer service, ensuring that your procurement process is smooth and efficient.

In addition to supplying aluminum profiles, we also offer competitive pricing to help you optimize your project budget. Our strong partnership with manufacturers allows us to negotiate the best deals, ensuring that you receive high-quality products at the most favorable prices.

Furthermore, our technical support team is available to assist you throughout your project. Whether you have questions about product specifications, installation guidelines, or any other technical matters, our experts are here to provide the necessary guidance and support.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have a solid foundation and resources to fulfill your aluminum profiles needs. Our commitment to excellence and customer satisfaction has earned us a reputation as a reliable and trusted supplier in the industry.

Contact us today to discuss your aluminum profiles requirements in Armenia. We are here to provide you with comprehensive services and support to ensure the success of your projects.

In addition to supplying aluminum profiles, we also offer competitive pricing to help you optimize your project budget. Our strong partnership with manufacturers allows us to negotiate the best deals, ensuring that you receive high-quality products at the most favorable prices.

Furthermore, our technical support team is available to assist you throughout your project. Whether you have questions about product specifications, installation guidelines, or any other technical matters, our experts are here to provide the necessary guidance and support.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have a solid foundation and resources to fulfill your aluminum profiles needs. Our commitment to excellence and customer satisfaction has earned us a reputation as a reliable and trusted supplier in the industry.

Contact us today to discuss your aluminum profiles requirements in Armenia. We are here to provide you with comprehensive services and support to ensure the success of your projects.