All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

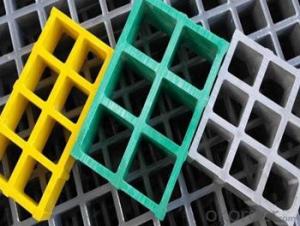

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are FRP pultrusion profiles tested for quality and performance?

FRP pultrusion profiles are tested for quality and performance through various methods such as mechanical testing, dimensional analysis, visual inspection, and chemical resistance evaluation. Mechanical tests involve subjecting the profiles to tension, compression, flexural, and impact tests to assess their strength, stiffness, and durability. Dimensional analysis ensures that the profiles meet the specified size and shape requirements. Visual inspection is carried out to identify any surface defects or imperfections. Additionally, chemical resistance tests assess the profiles' ability to withstand exposure to different chemicals and environments. These comprehensive testing procedures ensure that FRP pultrusion profiles meet the necessary quality and performance standards.

Can FRP pultrusion profiles be used in the construction of utility poles?

Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of utility poles. FRP pultrusion profiles offer several advantages such as being lightweight, corrosion-resistant, and possessing high strength-to-weight ratio, making them suitable for utility pole construction. Additionally, FRP pultrusion profiles are non-conductive, making them ideal for electrical applications where safety is a concern.

Are FRP pultrusion profiles resistant to organic acids?

Yes, FRP pultrusion profiles are generally resistant to organic acids due to their inherent corrosion resistance properties. The combination of reinforcing fibers and resin matrix in FRP pultrusions provide excellent resistance against organic acids, making them suitable for applications where exposure to such chemicals may occur. However, the specific resistance can vary depending on the type and concentration of the organic acid, as well as the specific composition of the FRP profile.

Wholesale FRP Pultrusion Profiles from supplier in Armenia

Our team is highly knowledgeable about FRP Pultrusion Profiles and can assist you in selecting the right profiles for your specific needs. We can provide technical support and guidance throughout the entire process, from product selection to installation. We work closely with our clients to understand their requirements and provide customized solutions that meet their unique project requirements.

Our FRP Pultrusion Profiles are manufactured using high-quality materials and advanced technologies to ensure durability and strength. They are designed to withstand harsh environmental conditions, making them suitable for various applications such as construction, infrastructure, transportation, and more.

In addition to our extensive product range, we also offer competitive pricing and efficient delivery services to ensure that your projects are completed on time and within budget. Our goal is to exceed customer expectations and provide exceptional service from start to finish.

Whether you are a contractor, engineer, or project manager, we are here to support you in all your FRP Pultrusion Profiles needs. Contact us today to discuss your requirements, and let us help you find the best solutions for your projects in Armenia.

Our FRP Pultrusion Profiles are manufactured using high-quality materials and advanced technologies to ensure durability and strength. They are designed to withstand harsh environmental conditions, making them suitable for various applications such as construction, infrastructure, transportation, and more.

In addition to our extensive product range, we also offer competitive pricing and efficient delivery services to ensure that your projects are completed on time and within budget. Our goal is to exceed customer expectations and provide exceptional service from start to finish.

Whether you are a contractor, engineer, or project manager, we are here to support you in all your FRP Pultrusion Profiles needs. Contact us today to discuss your requirements, and let us help you find the best solutions for your projects in Armenia.

Hot Search

- Fiberglass Chopped Strand in Afghanistan

- Fiberglass Mesh Cloth in Rwanda

- Composite Pipes in Mongolia

- FRP Pultrusion Profiles in Sweden

- Fiberglass Mat Tissue in Papua New Guinea

- Fiberglass Fabrics in America

- Fiberglass Mesh in Djibouti

- Composite Tank in Qatar

- Fiberglass Mesh tape in Monaco

- Polymer in Poland