All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

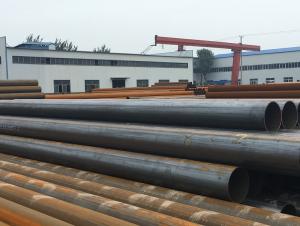

- - Seamless Steel Pipe

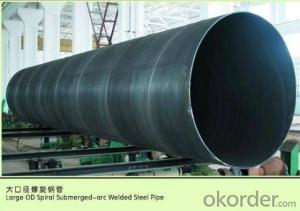

- - Welded Steel Pipe

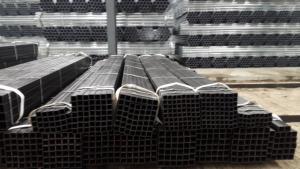

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the different mechanical testing requirements for seamless steel pipe?

The different mechanical testing requirements for seamless steel pipe include tensile testing, hardness testing, impact testing, and bend testing. These tests are conducted to ensure the pipe's strength, durability, and resistance to external forces and impacts. Tensile testing measures the pipe's ability to withstand pulling forces, hardness testing determines its resistance to indentation or scratching, impact testing assesses its toughness under sudden loadings, and bend testing checks its flexibility and ability to withstand bending without cracking or breaking. These tests help ensure the quality and reliability of seamless steel pipes.

What are the different types of corrosion protection for seamless steel pipe?

There are several types of corrosion protection methods for seamless steel pipes, including:

1. Coatings: Applying an anti-corrosion coating, such as epoxy, polyethylene, or fusion-bonded epoxy (FBE), to the surface of the pipe. These coatings act as a barrier between the steel and the corrosive environment.

2. Cathodic Protection: Using an impressed current or sacrificial anode system to provide a protective electrical current that counteracts the corrosion process. This method is particularly effective in underground or submerged environments.

3. Linings: Applying a corrosion-resistant lining, such as cement mortar or polyurethane, on the inner surface of the pipe. This protects the steel from corrosive substances flowing through the pipe.

4. Wrapping: Using corrosion-resistant tapes or wraps, such as polyethylene or polypropylene, to cover the pipe's surface. This provides a physical barrier against moisture and corrosive elements.

It is common to employ a combination of these methods to ensure maximum corrosion protection for seamless steel pipes, depending on the specific application and environmental conditions.

Can seamless steel pipes be used for aerospace manufacturing?

Yes, seamless steel pipes can be used for aerospace manufacturing. They are commonly used in the aerospace industry due to their high strength, durability, and resistance to extreme temperatures and pressures. Seamless steel pipes are often utilized in the construction of aircraft structures, engines, and fuel systems, among other applications.

What are the common uses of seamless steel pipes in the automotive industry?

Seamless steel pipes are commonly used in the automotive industry for various applications such as fuel and hydraulic lines, exhaust systems, chassis components, and structural parts. These pipes provide excellent strength and durability, ensuring efficient performance and safety in vehicles. The seamless construction eliminates the risk of leaks and enhances the overall efficiency of fluid transportation systems in automobiles.

Wholesale Seamless Steel Pipe from supplier in Armenia

Our team of professionals is dedicated to delivering high-quality products and services that meet your specific needs. We understand that each project is unique, and we strive to provide personalized solutions that ensure the success of your ventures.

Whether you require Seamless Steel Pipes for construction projects, industrial applications, or any other purpose, we have the expertise and resources to meet your requirements. Our seamless procurement solutions streamline the purchasing process, saving you time and effort.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. From initial design and planning to installation and maintenance, our team is available to provide guidance and assistance whenever needed.

At our company, we prioritize customer satisfaction above all else. We go above and beyond to ensure that our customers receive the highest level of service and support. We are dedicated to building long-term relationships with our clients and becoming their trusted partner for all their Seamless Steel Pipe needs in Armenia.

Contact us today to discuss your requirements and discover how we can help you achieve your goals. Together, we can create a seamless and successful future for your projects.

Whether you require Seamless Steel Pipes for construction projects, industrial applications, or any other purpose, we have the expertise and resources to meet your requirements. Our seamless procurement solutions streamline the purchasing process, saving you time and effort.

Furthermore, our technical support services are designed to assist you throughout the entire project lifecycle. From initial design and planning to installation and maintenance, our team is available to provide guidance and assistance whenever needed.

At our company, we prioritize customer satisfaction above all else. We go above and beyond to ensure that our customers receive the highest level of service and support. We are dedicated to building long-term relationships with our clients and becoming their trusted partner for all their Seamless Steel Pipe needs in Armenia.

Contact us today to discuss your requirements and discover how we can help you achieve your goals. Together, we can create a seamless and successful future for your projects.