All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the differences between hot-dip and pre-painted aluminum coil coatings?

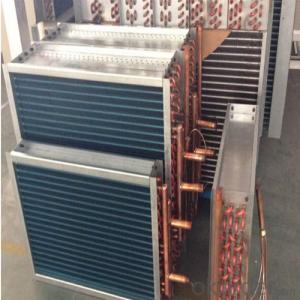

Hot-dip aluminum coil coatings involve the process of immersing the aluminum coil into a bath of molten coating material, which then adheres to the surface of the coil through a chemical reaction. On the other hand, pre-painted aluminum coil coatings are applied to the coil surface using a mechanical or electrostatic method before it is cured in an oven.

The main difference between the two is the application process. Hot-dip coatings provide a thicker and more durable coating, as the molten material fully bonds with the aluminum surface. This results in excellent corrosion resistance and overall durability. Pre-painted coatings, on the other hand, offer a more precise and consistent application, allowing for a wide range of colors and finishes. However, the coating thickness is generally thinner compared to hot-dip coatings, which may affect their long-term durability.

In summary, hot-dip coatings provide superior durability and corrosion resistance, while pre-painted coatings offer a wider range of colors and finishes. The choice between the two depends on the specific requirements of the application, such as the desired appearance, level of corrosion resistance needed, and budget constraints.

What are the methods for coloring aluminum coils?

There are several methods for coloring aluminum coils, including anodizing, powder coating, and coil coating. Anodizing involves creating a protective oxide layer on the surface of the aluminum through an electrolytic process, which can be colored using dyes. Powder coating involves applying a dry powder to the surface of the aluminum, which is then heated to create a durable and colorful coating. Coil coating is a process where the aluminum coil is coated with a liquid paint, which is then cured to create a smooth and long-lasting colored finish.

How are aluminum coils treated to enhance their resistance to UV radiation in outdoor applications?

Aluminum coils are treated with a protective coating or paint containing UV stabilizers to enhance their resistance to UV radiation in outdoor applications. These UV stabilizers act as a barrier, absorbing and reflecting the harmful UV rays, preventing them from penetrating the surface of the aluminum coil. This treatment helps to extend the lifespan of the aluminum coil and maintain its performance and appearance in outdoor environments exposed to sunlight.

Wholesale Aluminum Coils from supplier in America

We understand the importance of timely delivery and consistent quality, which is why we prioritize efficient logistics and ensure that our Aluminum Coils products meet the highest industry standards. Our team of experts is dedicated to providing personalized customer service, assisting you with product selection, customization, and technical specifications.

Whether you are looking for Aluminum Coils for construction, transportation, or any other industry application, we have a wide range of options to meet your specific requirements. Our Aluminum Coils are sourced from trusted manufacturers and undergo strict quality control measures to ensure durability and performance.

In addition to our reliable supply chain, we also offer competitive pricing to help you optimize your procurement costs. We understand the importance of cost-efficiency without compromising on quality, and strive to provide the best value for your investment.

At CNBM, we believe in building long-term partnerships with our clients. We are committed to your success and aim to provide ongoing support throughout your projects. Our knowledgeable team is always available to assist you with any questions or concerns, ensuring a smooth and hassle-free experience.

Choose us as your trusted supplier of Aluminum Coils in America, and experience the difference of working with a reliable and dedicated partner. Contact us today to discuss your Aluminum Coils requirements and let us provide you with the best solutions for your business.

Whether you are looking for Aluminum Coils for construction, transportation, or any other industry application, we have a wide range of options to meet your specific requirements. Our Aluminum Coils are sourced from trusted manufacturers and undergo strict quality control measures to ensure durability and performance.

In addition to our reliable supply chain, we also offer competitive pricing to help you optimize your procurement costs. We understand the importance of cost-efficiency without compromising on quality, and strive to provide the best value for your investment.

At CNBM, we believe in building long-term partnerships with our clients. We are committed to your success and aim to provide ongoing support throughout your projects. Our knowledgeable team is always available to assist you with any questions or concerns, ensuring a smooth and hassle-free experience.

Choose us as your trusted supplier of Aluminum Coils in America, and experience the difference of working with a reliable and dedicated partner. Contact us today to discuss your Aluminum Coils requirements and let us provide you with the best solutions for your business.