All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Aluminum StripsView More

Aluminum SheetsView More

Aluminum CoilsView More

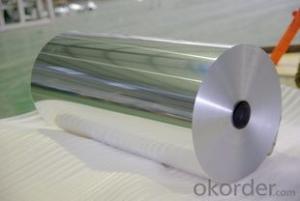

Aluminum FoilsView More

Aluminum ProfilesView More

Q & A

What is the history of aluminum production and use?

Aluminum production and use have a rich history that dates back thousands of years. Although aluminum is one of the most abundant elements on Earth, it was not until the 19th century that a commercially viable method for extracting it was developed. In 1825, Danish chemist Hans Christian Ørsted first isolated aluminum, but it was a costly and time-consuming process.

However, in 1886, Charles Martin Hall, an American chemist, and Paul Héroult, a French engineer, independently discovered the Hall-Héroult process. This revolutionary method involved the electrolysis of aluminum oxide, also known as alumina, to produce pure aluminum. The Hall-Héroult process drastically reduced the cost of aluminum production, making it more accessible and commercially viable.

The early 20th century witnessed a significant increase in aluminum production as it became an essential material for various industries. During World War I, aluminum's lightweight and corrosion-resistant properties made it a crucial material for aircraft manufacturing. The demand for aluminum skyrocketed further during World War II, as it was used in diverse applications such as weapons, vehicles, and aircraft.

Since then, aluminum has continued to be a vital material in industries like construction, transportation, packaging, and electronics. Its low density, high strength, and excellent recyclability have made it a popular choice for products ranging from airplanes and cars to beverage cans and smartphones.

In recent years, there has been a growing emphasis on sustainability and environmental conservation, leading to increased efforts in aluminum recycling. The energy required to recycle aluminum is significantly lower than that needed for primary production, making it an environmentally friendly choice.

Overall, the history of aluminum production and use reflects its transformative impact on various industries and its evolution from a precious metal to a widely available and versatile material.

What are the primary uses of aluminum in modern industry?

The primary uses of aluminum in modern industry include manufacturing of transportation vehicles, construction materials, electrical wiring, packaging materials, and consumer electronics.

Wholesale Aluminum from supplier in Tuvalu

We understand the unique requirements of the Tuvalu market and can offer customized solutions to meet your specific needs. Our wide range of Aluminum products includes aluminum sheets, plates, coils, extrusions, and profiles, all manufactured to the highest quality standards.

In addition to supplying Aluminum products, we also provide sales and technical support services. Our team of experts is well-versed in the technical aspects of Aluminum and can assist you in choosing the right products for your projects. We can provide detailed product information, specifications, and technical advice to ensure you make informed decisions.

Furthermore, we offer competitive pricing and timely delivery to ensure your projects stay on schedule and within budget. We have a strong logistics network and can efficiently handle the transportation of Aluminum products to Tuvalu. Our goal is to provide a hassle-free procurement experience for our customers.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver comprehensive Aluminum procurement services. CNBM is a trusted name in the industry, known for its commitment to quality and customer satisfaction.

Contact us today for all your Aluminum procurement needs in Tuvalu. We are dedicated to providing exceptional service and value to our customers. Let us be your trusted partner in the Aluminum supply chain.

In addition to supplying Aluminum products, we also provide sales and technical support services. Our team of experts is well-versed in the technical aspects of Aluminum and can assist you in choosing the right products for your projects. We can provide detailed product information, specifications, and technical advice to ensure you make informed decisions.

Furthermore, we offer competitive pricing and timely delivery to ensure your projects stay on schedule and within budget. We have a strong logistics network and can efficiently handle the transportation of Aluminum products to Tuvalu. Our goal is to provide a hassle-free procurement experience for our customers.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver comprehensive Aluminum procurement services. CNBM is a trusted name in the industry, known for its commitment to quality and customer satisfaction.

Contact us today for all your Aluminum procurement needs in Tuvalu. We are dedicated to providing exceptional service and value to our customers. Let us be your trusted partner in the Aluminum supply chain.